Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring Various Conveyor Roller Types and Their Applications in Industry

Different Types of Conveyor Rollers A Comprehensive Overview

Conveyor rollers play a crucial role in material handling systems across various industries. These cylindrical components are designed to facilitate the movement of goods, from heavy pallets in warehouses to delicate products in manufacturing processes. The effectiveness and efficiency of a conveyor system often hinge on the choice of rollers. In this article, we will explore the different types of conveyor rollers and their applications.

1. Standard Rollers

Standard rollers are the most commonly used type in conveyor systems. Typically made from steel or plastic, they are designed to support the weight of the conveyed materials while allowing for smooth movement along the conveyor belt. Standard rollers can be either straight or tapered, depending on the application. They are widely used in industries such as warehousing, packaging, and general manufacturing due to their versatility.

2. Impact Rollers

Impact rollers are designed to handle heavy loads and severe conditions, particularly at loading zones. Constructed with a thicker and more robust design than standard rollers, they are equipped with a rubber cover that helps absorb shock and reduce wear and tear. This makes them ideal for operations that involve heavy machinery or the frequent transfer of bulky items. Their durability promotes longevity and reduced maintenance costs, making them a valuable asset in any heavy-duty conveyor system.

Guide rollers help to keep the conveyor belt aligned as it traverses from one point to another. They are essential for preventing misalignment and ensuring that products move smoothly along the conveyor system. Guide rollers can be adjustable and are typically used in curves, inclines, and declines within conveyors. By maintaining proper alignment, they contribute to the overall efficiency of the material handling process.

different types of conveyor rollers

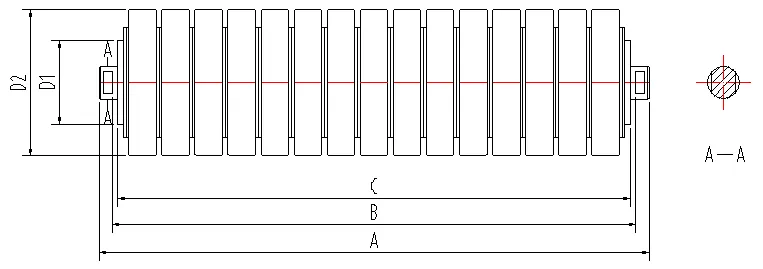

4. Idler Rollers

Idler rollers are typically used to support the conveyor belt and maintain its tension. These rollers do not receive any drive power but are crucial for maintaining the proper shape and alignment of the belt. Idler rollers come in various designs, including flat and grooved profiles. They can also vary in material, with options ranging from metal to plastic, depending on the specific requirements of the application.

5. Driven Rollers

Driven rollers are powered rollers that receive energy from a motor or drive system. They are used in powered roller conveyors where the movement of goods occurs through the rollers themselves rather than through a belt. Driven rollers can be controlled independently, allowing for more flexible system design and layout. They are prevalent in applications that require controlled movement, such as sorting systems or automated assembly lines.

6. Specialty Rollers

Specialty rollers are designed for specific applications and may have unique properties. Examples include stainless steel rollers for food processing industries, anti-static rollers for handling electronic components, and friction rollers that provide added grip for specific items. These rollers are engineered to meet unique operational challenges and ensure the safe and efficient transport of goods.

Conclusion

The selection of the appropriate type of conveyor roller is essential for optimizing operational efficiency, reducing downtime, and maximizing productivity in material handling systems. Understanding the differences among standard, impact, guide, idler, driven, and specialty rollers allows businesses to make informed decisions that meet their specific needs. As technology evolves, so too will the designs and materials used in conveyor rollers, further enhancing their capabilities and applications across diverse industries. Choosing the right roller not only facilitates effective movement but also ensures the longevity and reliability of the entire conveyor system.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025