Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor component

Understanding Conveyor Components The Backbone of Efficient Material Handling

In today's fast-paced industrial world, efficiency is a top priority. One of the most vital systems that contribute to operational efficiency across various sectors is the conveyor system. At the heart of this technology are conveyor components, each playing a crucial role in ensuring that materials and products move seamlessly from one point to another. Understanding these components is essential for optimizing performance, enhancing productivity, and maintaining safety in any material handling operation.

What are Conveyor Components?

Conveyor components refer to the various parts that make up a conveyor system. These systems can be divided into several types, including belt conveyors, roller conveyors, modular conveyors, and more, each serving specific needs depending on the application. The primary conveyor components include the following

1. Conveyor Belts The most visible component, conveyor belts transport materials along the system. They can differ in material composition, width, thickness, and length, tailored to the products being carried. Rubber, PVC, and metal are common materials used for belts, selected based on the environmental conditions and the nature of the goods.

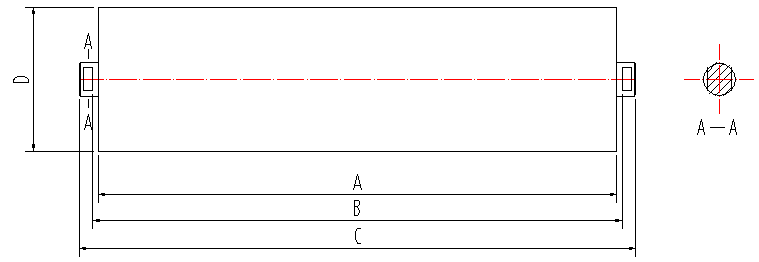

2. Rollers These are cylindrical components that support the conveyor belt. They play a critical role in reducing friction, facilitating smooth movement. Rollers can be either powered or non-powered, with many configurations available, catering to various load types and operational speeds.

3. Drives The drive system consists of motors and gearboxes that provide the necessary power to move the conveyor belt. The choice of drive system is critical, as it needs to accommodate the load requirements and the operational speed desired for the conveyor system.

4. Idlers Often found within the conveyor assembly, idlers support the conveyor belt’s structure and maintain its alignment. Idlers help in reducing the belt's sagging, ensuring proper tension and preventing belt wear.

5. Frames The frame is the backbone of the conveyor system, providing structural support. Typically made from metal or robust plastic, frames are designed to withstand the weights and stresses exerted by moving materials.

6. Sensors and Controls Modern conveyor systems often include advanced sensors and control mechanisms. These components monitor the system's operation, ensuring proper functioning and preventing faults. They can also automate processes, enhancing efficiency and safety.

conveyor component

7. Safety Devices Given the moving parts and operational risks associated with conveyor systems, safety devices are indispensable. These may include emergency stops, safety guards, and sensors that detect blockages or misalignments, ensuring the safety of employees and equipment.

Importance of Conveyor Components

The significance of conveyor components extends beyond mere transportation. A well-designed conveyor system enhances productivity by streamlining the movement of goods, reducing manual handling, and minimizing downtime. By optimizing the selection and integration of conveyor components, businesses can achieve smoother workflows and faster turnaround times.

Moreover, the durability and reliability of conveyor components directly impact the maintenance costs and lifespan of the conveyor system. High-quality components reduce the frequency of repairs and replacements, translating into lower operational costs. Additionally, investing in suited conveyor components tailored to specific operational needs can enhance energy efficiency, contributing to sustainability goals.

Trends and Innovations

The conveyor systems of today are evolving, thanks to continued advancements in technology. Innovations such as smart conveyors equipped with IoT devices enable real-time monitoring and predictive maintenance. This technology allows companies to identify potential failures before they occur, optimizing maintenance schedules and minimizing disruptions.

Furthermore, advancements in materials science have led to the development of lighter yet more durable conveyor components. This reduces energy consumption and enhances the performance of conveyor systems.

Conclusion

Conveyor components are fundamental to the reliable operation of conveyor systems. Understanding their roles and functionalities is vital for anyone involved in material handling operations. As technology continues to evolve, so too will the components that enable these systems, making them more efficient, safer, and more adaptable to diverse industrial needs. Investing time and resources into selecting the right conveyor components can lead to significant improvements in productivity, safety, and overall operational success.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025