Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Premium Take Up Pulley Durable Solutions for Belt Conveyor Systems

(take up pulley)

The Essential Role of Take Up Pulleys in Modern Material Handling

This comprehensive guide examines take up pulley

systems in industrial applications, addressing their critical functions and technical evolution. Key discussion points include:

- Fundamental mechanics of tension regulation in belt conveyors

- Quantifiable performance impacts on operational efficiency

- Technical innovations enhancing component reliability

- Comparative evaluation of leading manufacturers

- Customization approaches for industry-specific challenges

- Field-proven solutions in demanding operational environments

- Future engineering developments for next-generation systems

Precision Tension Control Mechanics

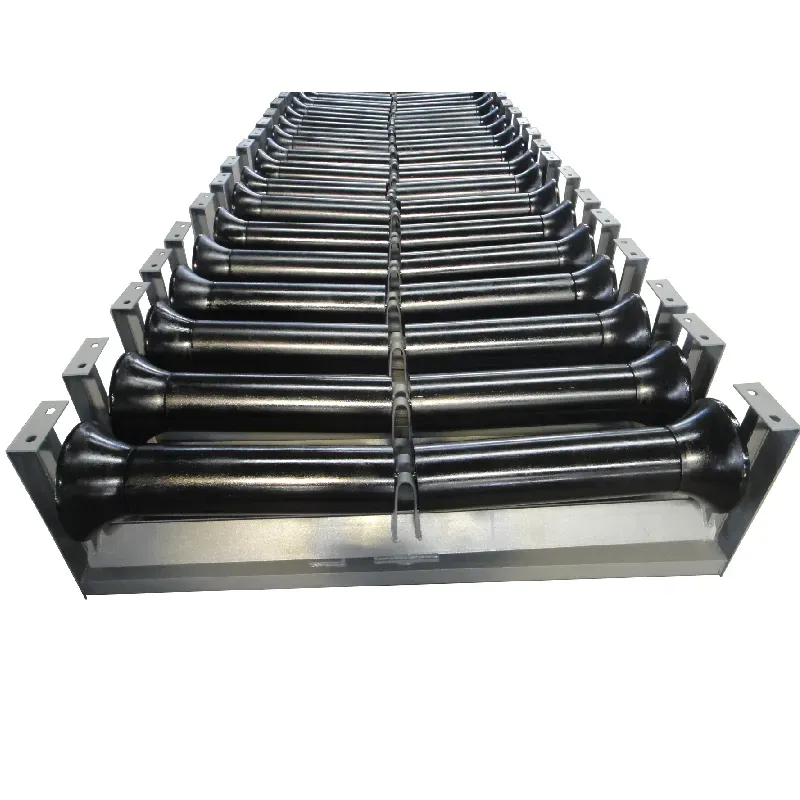

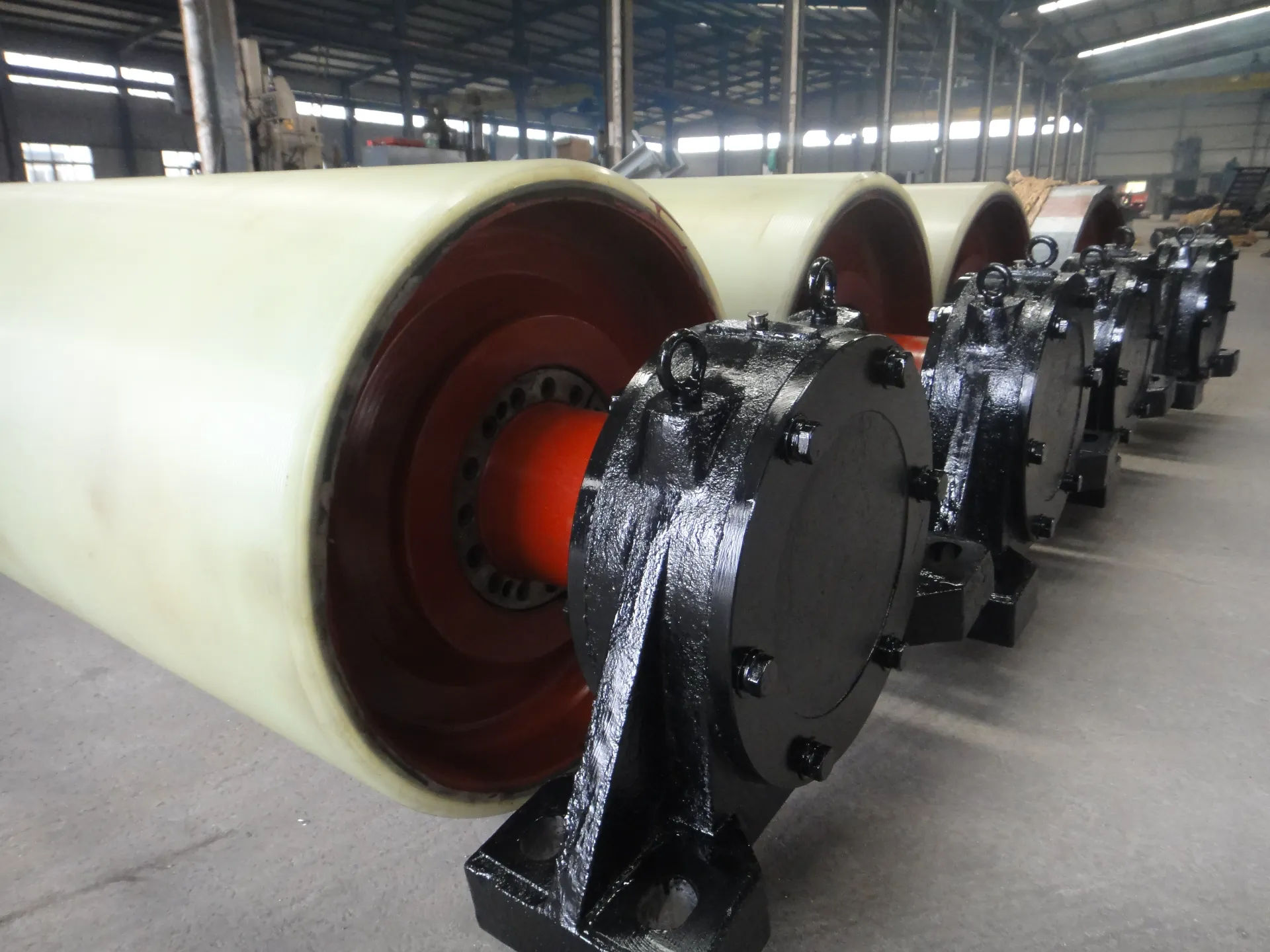

Take up pulleys constitute the operational core of belt conveyor tension regulation. These specialized components dynamically maintain optimal belt tautness through either gravitational force (gravity take up pulley systems) or mechanical adjustment mechanisms (tail pulley take up assemblies). Positioned strategically at conveyor ends, they compensate for belt elongation caused by operational loads and temperature fluctuations. Engineering data reveals proper tensioning reduces belt slip incidents by 62% and extends belt service life by approximately 40% in standard mineral handling applications.

Quantified System Performance Metrics

Operational metrics demonstrate the critical impact of properly configured systems. According to bulk handling industry reports (2023), facilities with optimized tensioning mechanisms achieved:

- 18-23% higher throughput capacity compared to manual tensioning systems

- Reduced power consumption (7.4kWh average savings per operational ton)

- 72% decrease in emergency maintenance downtime

Gravity take up pulley configurations particularly excel in continuous mining operations where autonomous tensioning maintains constant load distribution, preventing catastrophic slippage events that cost enterprises an average of $42,000 per incident (Mining Operations Journal, 2022).

Engineering Innovations and Robust Construction

Advanced manufacturing techniques have significantly enhanced durability. Modern take up pulley designs incorporate:

Material science advancements:

- Xylan-coated steel drums increasing abrasion resistance by 300%

- Ceramic-lagging surfaces enhancing traction coefficients to 0.52μ

Structural integrity features:

- Finite element analysis-optimized shell thickness (minimum 16mm)

- Self-cleaning concentric shaft assemblies preventing material buildup

Recent stress testing (ASTM B117-19 protocol) confirmed modern units withstand 92,000 operational hours before requiring relagging - a 37% improvement over previous generation models.

Comparative Analysis of Industry Manufacturers

| Manufacturer | Max Load Rating | Lagging Options | Temperature Range | Customization Capacity | Maintenance Interval |

|---|---|---|---|---|---|

| Flexco HD-Series | 250 kN | Ceramic/Diamond | -40°C to +120°C | Modular | 24 months |

| Rulmeca Group XP | 320 kN | Rubber/Polyurethane | -30°C to +150°C | Full bespoke | 36 months |

| Siemens SIMP | 280 kN | Ceramic/Steel | -50°C to +85°C | Limited | 18 months |

| Martin Engineering | 300 kN | Rubber/Phenolic | -20°C to +130°C | Configuration | 30 months |

Industry leader Rulmeca's gravity take up pulley systems with polyurethane lagging demonstrated exceptional longevity in abrasive material tests, maintaining surface integrity through 15,000 operational hours.

Industry-Specific Engineering Solutions

Tailoring take up pulley in belt conveyor systems addresses distinct operational requirements:

Mining sector: Chromium-reinforced assemblies withstand impact loads exceeding 22kJ

Food processing: FDA-compliant stainless steel constructions with CIP compatibility

Port operations: Saltwater-resistant polymer composites preventing corrosion failure

Rio Tinto's Pilbara iron ore operation implemented hydraulic tail pulley take up units with load-sensing automation, reducing tension-related stoppages by 83% while handling 6,000 metric tons/hour. The system self-adjusts within 0.5% tolerance during load fluctuations between 30-100% capacity.

Case Study: Cement Production Efficiency Improvement

LafargeHolcim's Montana plant documented significant gains after upgrading their take up pulley systems:

- Conveyor 3: Installed automated gravity take up pulley with ceramic lagging

- Conveyor 7: Retrofitted hydraulic tail pulley take up assembly

Both systems incorporated predictive tension algorithms monitoring belt elongation. Results over 18 months:

- Energy consumption reduction: 14.7% average across both conveyors

- Belt replacement frequency decreased from quarterly to biannual

- Conveyor stoppages reduced by 67 hours monthly

- Calculated ROI period: 9.8 months

Next-Generation Take Up Pulley Technologies

Innovations currently in field testing include IoT-integrated tension monitoring with real-time data analytics, predicting maintenance needs with 94% accuracy before visible symptoms manifest. New composite materials under development promise to extend operational boundaries to temperatures exceeding +200°C while sustaining 350kN loads. Leading manufacturers are redesigning take up pulley assemblies with modular components that decrease replacement downtime by 65%, ensuring these critical components continue evolving with Industry 4.0 demands.

(take up pulley)

FAQS on take up pulley

Q: What is a take up pulley?

A: A take up pulley is a critical component in belt conveyors used to adjust belt tension. It maintains optimal tension to prevent slippage and ensure efficient material handling. Proper adjustment minimizes wear and extends conveyor life.Q: How does a take up pulley function in a belt conveyor?

A: In belt conveyors, the take up pulley absorbs belt slack and compensates for elongation or shrinkage. It applies controlled tension to the belt, ensuring smooth operation and tracking. This prevents misalignment and reduces maintenance downtime.Q: What is the role of a tail pulley in a take up system?

A: The tail pulley take up anchors the belt's return end and adjusts tension via manual or automatic mechanisms. It counteracts belt stretch caused by load or temperature changes, maintaining consistent traction. Correct positioning minimizes belt wear and slippage.Q: How does a gravity take up pulley work?

A: A gravity take up pulley uses weights or counterbalances to apply tension automatically. As the belt stretches, the pulley descends under gravitational force, maintaining constant pressure. This passive system is reliable and requires minimal manual intervention.Q: Why is regular maintenance crucial for take up pulleys?

A: Maintenance prevents failures like belt misalignment or excessive wear. Inspect pulleys for debris, bearing damage, and corrosion monthly. Proper lubrication ensures smooth operation and avoids costly conveyor shutdowns.-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025