Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor belt return rollers

Understanding Conveyor Belt Return Rollers Essential Components for Efficient Material Handling

Conveyor belt systems play a crucial role in various industries, from manufacturing and mining to logistics and distribution. Among the many essential components that ensure the smooth operation of these systems, return rollers are often overlooked yet fundamental to maintaining efficiency and stability. In this article, we will delve into the function, types, and importance of conveyor belt return rollers.

What Are Conveyor Belt Return Rollers?

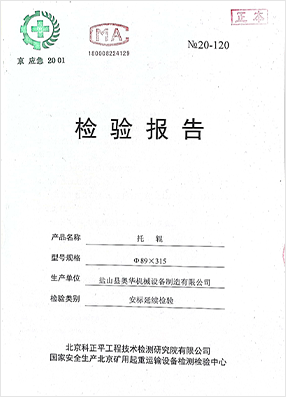

Return rollers are cylindrical components positioned underneath the conveyor belt, serving the primary purpose of supporting the belt as it returns to the starting point. Unlike the carrying rollers, which support the loaded portion of the belt, return rollers are designed to handle the weight of the belt while it is empty. This role is critical as it aids in minimizing friction and wear on the conveyor system.

Functions of Return Rollers

1. Support and Stability Return rollers provide the necessary support for the belt during its return journey. By maintaining proper tension and alignment, they help prevent sagging and misalignment, which can lead to increased wear and tear on both the belt and the rollers.

2. Reduction of Friction Efficient material handling requires the smooth operation of conveyor belts. Return rollers contribute to this by reducing friction between the belt and the conveyor frame, ensuring that the belt moves freely. Decreasing friction not only improves efficiency but also extends the lifespan of both the conveyor system and its components.

3. Belt Cleaning Some return rollers are designed with features that aid in the cleaning of the conveyor belt as it passes over them. This is particularly beneficial in applications involving sticky materials, as it helps prevent the accumulation of debris that can affect the performance of the system.

4. Safety By providing stability and support, return rollers play a significant role in the overall safety of the conveyor system. Properly functioning rollers reduce the risk of belt slippage or breakdowns, which can pose hazards in an industrial environment.

Types of Return Rollers

conveyor belt return rollers

Return rollers come in various designs to cater to different applications and conveyor configurations

. The most common types include1. Flat Return Rollers These are the standard rollers used in most conveyor systems. They feature a smooth, cylindrical surface that allows the belt to glide back without much friction.

2. Crowned Return Rollers With a slightly raised center, crowned return rollers help keep the belt centered on the roller, thus preventing misalignment and guiding it back effectively.

3. Rubber-Coated Return Rollers These rollers come with a layer of rubber that provides enhanced grip and further reduces friction, which is particularly useful in heavy-duty applications.

4. Self-Cleaning Return Rollers Designed with specific shapes or grooves, these rollers help dislodge material that may stick to the belt, promoting better cleanliness and functionality.

Importance of Regular Maintenance

Despite their robust design, conveyor belt return rollers require regular maintenance to ensure optimal performance. Periodic inspection and lubrication help prevent rust and corrosion, while cleaning them from accumulated debris ensures that they work effectively. Neglecting maintenance can lead to premature wear and costly downtime.

Conclusion

Conveyor belt return rollers are vital components within material handling systems, providing essential support, reducing friction, and maintaining safety and efficiency. Understanding their crucial role and the different types available helps industries make informed decisions about their conveyor systems. By prioritizing regular maintenance, businesses can ensure the longevity and reliability of their conveyor systems, leading to smoother operations and enhanced productivity.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025