Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu troughing rollers manufacturers

Understanding Troughing Rollers Manufacturers and Their Importance

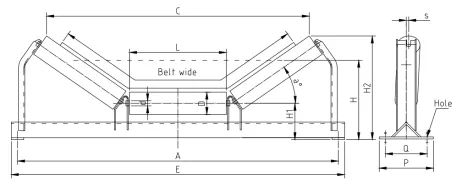

Troughing rollers are essential components in various conveyor systems, particularly in the bulk material handling industry. These rollers are designed to support and guide conveyor belts, allowing them to efficiently transport goods across different terrains and distances. The design features a positive curve that helps in forming a trough, which is crucial for controlling the path of the conveyed materials and minimizing spillage.

The Role of Troughing Rollers

The primary function of troughing rollers is to support the conveyor belt, ensuring that it remains in the correct alignment while facilitating material transfer. By providing a concave shape, these rollers help in maintaining the integrity of the load, reducing the risk of product loss and ensuring a smooth operation. Additionally, troughing rollers help in reducing friction between the belt and the rollers, which ultimately affects energy consumption and operational efficiency.

Manufacturers of Troughing Rollers

The demand for troughing rollers has seen significant growth thanks to the proliferation of industries that utilize conveyor systems, such as mining, agriculture, and packaging. A variety of manufacturers specialize in producing high-quality troughing rollers, and their offerings can significantly influence the performance of conveyor systems. When selecting a manufacturer, several key factors should be considered

1. Quality Standards Reputable manufacturers adhere to stringent quality control measures to ensure that their troughing rollers meet industry standards. Materials used in production must be durable and resistant to wear and tear, as they work in tough environments.

troughing rollers manufacturers

2. Customization Options Different applications require different specifications. Leading manufacturers offer customization services to cater to unique industry needs, allowing clients to specify dimensions, materials, and load capacities for their troughing rollers.

3. Technology and Innovation The best manufacturers invest in the latest technology to produce enhanced conveyor components. Innovative designs can lead to improved efficiency, reduced maintenance costs, and longer service life.

4. Customer Support A reliable manufacturer provides comprehensive customer support, including installation guidance, maintenance services, and after-sales support, ensuring that their products perform optimally throughout their lifespan.

Leading Players in the Market

Some prominent manufacturers of troughing rollers include companies with a global presence and a proven track record. Firms like Martin Engineering and Ashland Conveyor Products are known for their high-quality products and innovative solutions, while smaller, specialized companies often provide tailored services that cater to niche markets.

Conclusion

In conclusion, troughing rollers are vital components of conveyor systems, and selecting the right manufacturer can make a significant difference in operational efficiency and productivity. Industries relying on conveyor systems must carefully evaluate the qualities of their chosen manufacturer to ensure they receive superior products designed to meet their specific needs. By prioritizing quality, customization, and customer support, businesses can select troughing roller manufacturers that will contribute positively to their material handling processes, enhancing overall performance and reliability.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025