Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

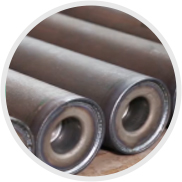

Zulu tail pulley

Understanding Tail Pulleys An Integral Component in Conveyor Systems

In various industries, especially those involving bulk material handling, conveyor systems play a crucial role in facilitating the efficient movement of goods. Among the essential components of these systems is the tail pulley, a part that, while often overlooked, ensures the smooth operation and longevity of the conveyor belt.

What is a Tail Pulley?

A tail pulley, sometimes referred to as a return pulley, is located at the end of a conveyor system. Its primary purpose is to support the conveyor belt as it returns to the head pulley after transporting materials. The tail pulley is essential to maintaining belt tension and alignment, which in turn prevents slippage and extends the lifespan of the conveyor belt.

Importance of Tail Pulleys

1. Belt Tension Maintenance Tail pulleys help in keeping the necessary tension on the conveyor belt. Proper tension is critical to prevent the belt from sagging or becoming misaligned, which can lead to operational inefficiencies and increased wear and tear.

2. Supporting Return Path As the belt traverses around the tail pulley, it enters the return phase. The tail pulley provides the necessary support to keep the belt in place, ensuring smooth movement back to the head pulley. This function is vital for uninterrupted operations in high-volume production settings.

3. Reduction of Wear and Tear The presence of a well-designed tail pulley can significantly minimize abrasion and damage to the conveyor belt. By allowing the belt to navigate smoothly without excessive friction or sharp angles, the tail pulley enhances the durability of the belt and reduces the need for frequent replacements.

4. Facilitating Maintenance Tail pulleys are often constructed to allow easy access for maintenance. Regular inspections and timely servicing of the tail pulley can prevent unexpected breakdowns and costly downtime. Maintenance might include checking for wear, ensuring proper alignment, and lubricating moving parts.

tail pulley

Design and Construction

Tail pulleys are typically made from robust materials such as steel, ensuring they can withstand the heavy loads and rugged conditions common in industrial environments. Their design often incorporates features like rubber lagging, which enhances traction between the belt and the pulley, further minimizing slippage.

In addition, the size and diameter of the tail pulley can vary depending on the specific requirements of the conveyor system. Larger pulleys may be used for high-capacity operations, while smaller ones might suffice for lighter applications.

Challenges and Considerations

While tail pulleys are integral to the smooth operation of conveyor systems, they are not without challenges. Misalignment or wear can lead to serious issues such as belt tracking problems, which can disrupt the entire system. Operators must regularly monitor the condition of tail pulleys to ensure they function optimally.

Furthermore, the environment in which the conveyor operates can impact tail pulley performance. Factors such as temperature, humidity, and exposure to corrosive materials must be considered when selecting materials and designs for tail pulleys.

Conclusion

In conclusion, tail pulleys are a vital component of conveyor systems, playing an essential role in belt maintenance, operational efficiency, and overall system reliability. Understanding their function and importance can lead to better designs, improved maintenance practices, and extended equipment life. As industries continue to evolve and expand, the role of tail pulleys will remain integral to achieving streamlined operations in material handling.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025