Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Efficient Solutions for Maintaining Clean Conveyor Scrapers and Enhancing Performance

The Importance of Scraper Belt Cleaners in Industrial Operations

In the realm of industrial operations, maintaining the efficiency of conveyor systems is crucial for productivity and safety. One of the key components in ensuring the longevity and performance of these systems is the scraper belt cleaner. This essential equipment plays a vital role in removing unwanted debris, materials, and contaminants from conveyor belts, thereby preventing operational setbacks and costly downtime.

Understanding Scraper Belt Cleaners

Scraper belt cleaners are devices designed to remove bulk material that adheres to the surface of conveyor belts during transport. These cleaners are typically installed at various points along the conveyor system, particularly at the discharge area where material is dropped off. The primary function of a scraper cleaner is to keep the belt surface clean, ensuring that the system operates smoothly and efficiently.

There are several types of scraper belt cleaners, each designed for specific applications and materials. Primary scrapers remove a substantial amount of carryback right after the material is discharged, while secondary scrapers provide additional cleaning power for any leftover material. These cleaners can be constructed from various materials such as rubber, polyurethane, and metal, each selected based on the type of material being conveyed and the operating conditions.

Benefits of Using Scraper Belt Cleaners

1. Enhanced Efficiency By effectively removing carryback, scraper belt cleaners maintain the integrity of the conveyor system. This allows the conveyor belts to function at optimal levels, reducing the need for frequent repairs or replacements. Consequently, businesses can experience increased throughput and reduced operational costs.

scraper belt cleaner

2. Improved Safety Accumulated materials around conveyor systems can pose significant safety hazards, including slip and trip hazards for personnel. Scraper belt cleaners mitigate these risks by ensuring that surfaces remain clean and free of excess material, thus promoting a safer working environment.

3. Environmental Responsibility Efficient material handling minimizes waste. Cleaning the conveyor belts reduces the amount of fine particles that may escape into the environment, thereby supporting eco-friendly practices within industrial operations. This not only helps in complying with environmental regulations but also enhances the company's reputation.

4. Reduced Maintenance Costs Investing in high-quality scraper belt cleaners can significantly decrease maintenance costs. With a cleaner belt surface, the conveyor systems experience less wear and tear, which translates to fewer breakdowns and a longer lifespan for the equipment.

5. Better Product Quality In industries where product integrity is critical, such as food and pharmaceuticals, maintaining a clean conveyor system ensures that there is no cross-contamination. This is particularly important in preventing defects or issues that could arise from residual materials on the conveyor belts.

Conclusion

In conclusion, scraper belt cleaners are indispensable tools in various industrial applications. Their ability to improve efficiency, enhance safety, and contribute to environmental responsibility makes them a worthy investment for any business relying on conveyor systems. As industries continue to pursue higher operational standards and sustainability, the utilization of scraper belt cleaners will undoubtedly play a critical role in achieving these goals. Therefore, it is essential for companies to consider integrating these cleaners into their operations to ensure optimal performance and a competitive edge in the market.

-

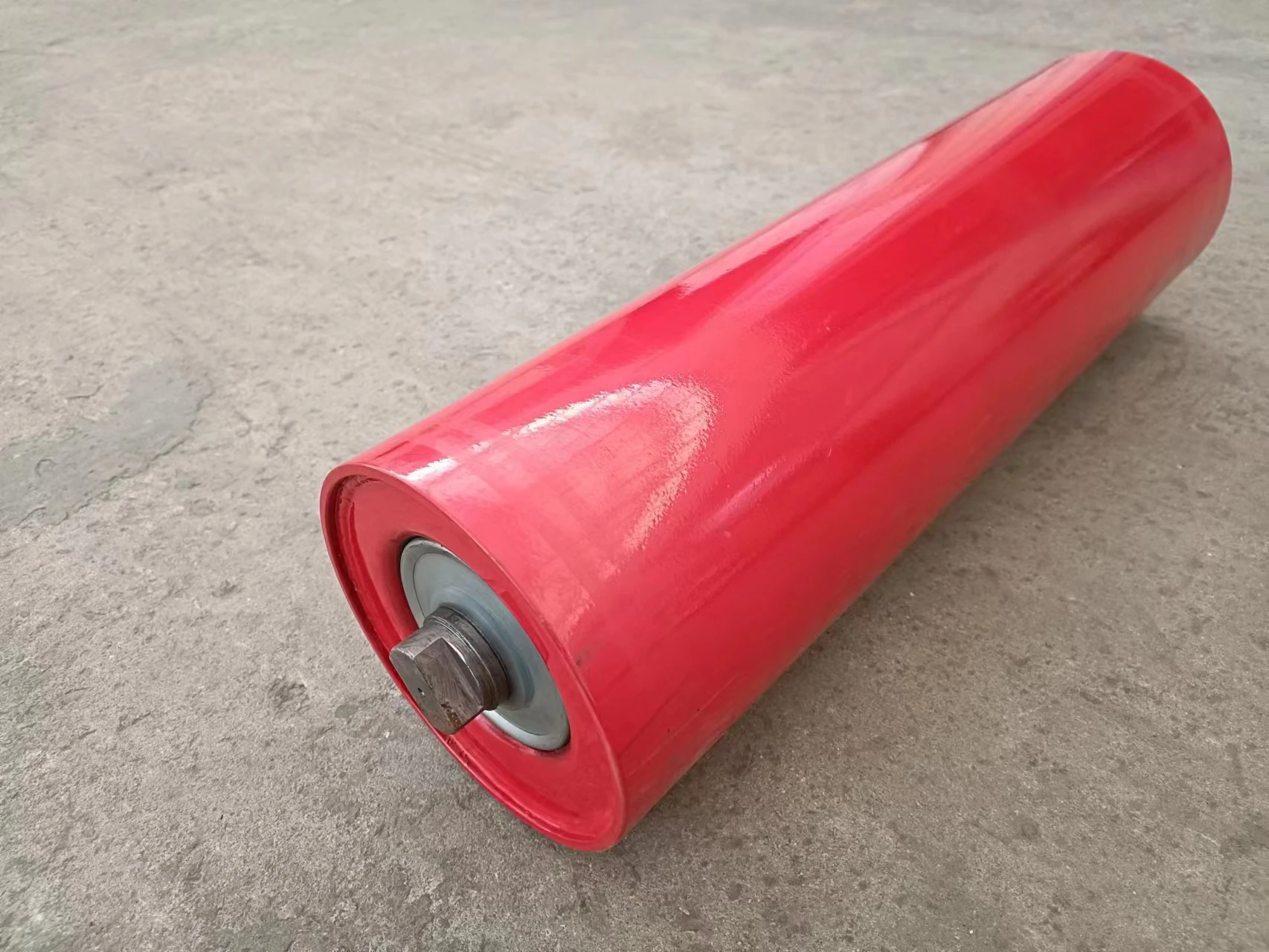

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025