Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

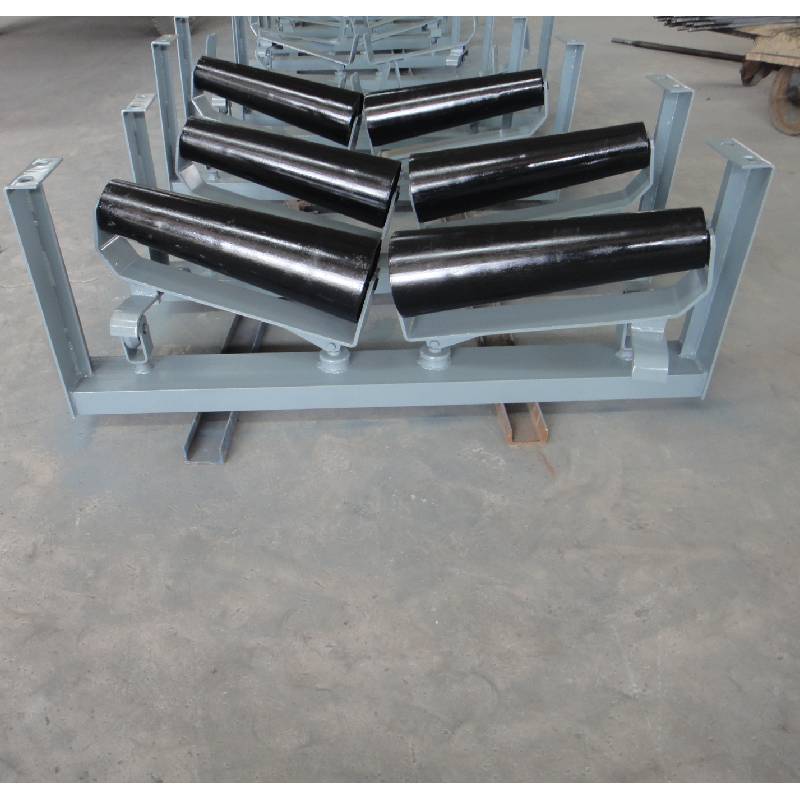

Zulu Rubber Disc Return Idlers for Efficient Conveyor System Performance and Durability

The Importance of Rubber Disc Return Idlers in Conveyor Systems

Conveyor systems play a crucial role in various industries, from manufacturing to mining, ensuring the efficient transport of materials. One critical component of these systems is the return idler, specifically rubber disc return idlers. Understanding their significance, functionality, and advantages can help organizations optimize their operations and enhance productivity.

What Are Rubber Disc Return Idlers?

Rubber disc return idlers are specialized components used in conveyor systems to support the return belt after it has completed its material-carrying phase. Unlike traditional idlers, which may consist of a solid cylindrical design, rubber disc return idlers feature a series of rubber discs that are spaced apart on the shaft. This unique design offers several benefits that make them particularly advantageous for various applications.

Functionality and Design

The primary function of return idlers is to maintain the alignment and tension of the conveyor belt as it returns to the head section. Rubber disc return idlers facilitate this process by providing a cushioning effect and reducing friction between the belt and the idler. Each rubber disc acts semi-independently, allowing for better adaptability to the belt’s movements and minimizing the risk of damage.

The spacing of the rubber discs plays a vital role in enhancing the overall efficiency of the conveyor system. With reduced contact area, the idlers allow for smoother operation, which can lead to lower energy consumption. Additionally, the ability of the rubber discs to flex provides better load distribution, reducing localized wear on the conveyor belt.

Benefits of Using Rubber Disc Return Idlers

rubber disc return idlers

1. Reduced Noise Levels One of the primary advantages of rubber disc return idlers is their capacity to minimize noise. The rubber material absorbs vibrations and shock, leading to quieter operation. This is particularly important in environments where noise control is a priority, such as in urban areas or near sensitive operations.

2. Lower Maintenance Requirements Rubber disc return idlers generally require less maintenance than traditional metal idlers. The cushioning effect of the rubber helps in extending the life of both the idlers and the conveyor belt, reducing the frequency of replacements and repairs.

3. Enhanced Load Support The design of rubber disc return idlers allows them to support heavier loads without compromising the belt's stability. This is particularly beneficial in applications involving moving bulk materials, where the weight can lead to deformation in conventional idlers.

4. Improved Belt Tracking Proper belt alignment is crucial to the efficiency of any conveyor system. Rubber disc return idlers help to ensure correct belt tracking by accommodating slight misalignments and guiding the belt back to its intended path.

5. Adaptability to Various Conditions Rubber disc return idlers are versatile and can be used in a wide range of environments, including those that are wet, dusty, or corrosive. The rubber material is resistant to certain chemicals and moisture, making it suitable for varying industrial contexts.

Conclusion

In summary, rubber disc return idlers offer a combination of advantages that can significantly enhance the performance of conveyor systems. By reducing noise, lowering maintenance needs, and improving load support and belt tracking, these idlers play an essential role in ensuring the longevity and efficiency of conveyor operations. As industries continue to evolve and demand more from their material handling systems, investing in high-quality components like rubber disc return idlers will remain a critical aspect of maintaining competitive edge and operational excellence.

Incorporating these advanced components not only optimizes performance but also contributes to the sustainability of industrial processes, making them an invaluable asset in today’s fast-paced manufacturing and logistics environments.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025