Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu rubber disc return idlers

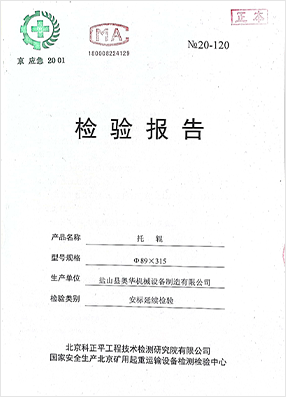

Rubber Disc Return Idlers Efficient Solutions for Conveyor Systems

Rubber disc return idlers play a pivotal role in the smooth and efficient operation of conveyor systems, essential components in various industries ranging from mining to manufacturing. As the backbone of material handling, these idlers ensure that material is transported with minimal friction and wear, enhancing the overall performance of conveyor belts.

The design of rubber disc return idlers is innovative and practical. They consist of a cylindrical body with rubber discs attached to the axis at regular intervals. This configuration allows the idler to reduce the contact area with the conveyor belt, thereby minimizing the friction between the belt and the idler. The use of rubber as a primary material offers several advantages — it is durable, flexible, and capable of absorbing shocks. This characteristic is particularly important in environments where heavy materials are transported or where the conveyor system operates under load variations.

One of the major benefits of rubber disc return idlers is their ability to enhance belt alignment. Misalignment can lead to belt wear, spillage of materials, and increased operational costs. The design of these idlers allows the conveyor belt to maintain better alignment as the discs effectively guide the belt back to its intended path. By minimizing misalignment, rubber disc return idlers not only extend the life of the conveyor belt but also improve the overall efficiency of the material handling process.

rubber disc return idlers

Another noteworthy aspect is the contribution of rubber disc return idlers to noise reduction. Conventional return idlers can produce significant noise due to the constant friction and contact. However, the rubber discs in these idlers create a cushioning effect, resulting in reduced noise levels. This is particularly advantageous in settings where reducing noise pollution is crucial for worker safety and comfort.

Installation and maintenance of rubber disc return idlers are also simplified when compared to traditional idler designs. Their modular design allows for easy assembly and disassembly, which can significantly decrease downtime during maintenance activities. Operators can quickly replace worn-out components, ensuring that the conveyor system remains in optimal operating condition.

In conclusion, rubber disc return idlers offer numerous advantages that make them an excellent choice for conveyor systems. Their ability to reduce friction, enhance belt alignment, decrease noise levels, and simplify maintenance not only improves the efficiency and durability of conveyor systems but also contributes to safer and more sustainable operations. As industries continue to seek innovative solutions for material handling challenges, rubber disc return idlers are poised to play an even more significant role in the advancement of conveyor technology. By investing in such solutions, companies can achieve higher productivity and efficiency, maintaining a competitive edge in the fast-paced industrial landscape.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025