Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Februari . 14, 2025 07:41

Back to list

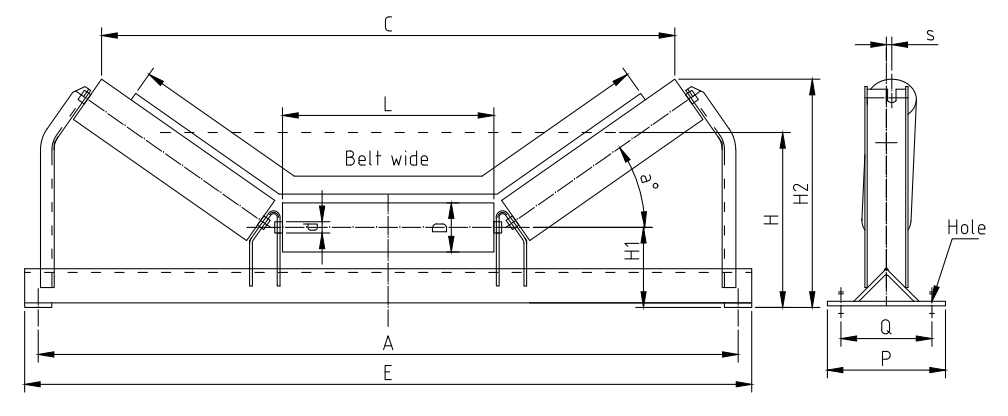

return roller

The return roller, an often overlooked component of conveyor systems, plays a vital role in the efficiency and reliability of industrial operations. These rollers are not only about providing return support to the empty belt before it re-engages with bulk material but are fundamental to ensuring smooth operation, minimizing downtime, and enhancing the overall productivity of conveyor systems across various industries.

Trustworthiness of return rollers is further augmented by their role in maintaining the structural integrity of conveyor systems. A reliable return roller can prevent issues such as conveyor belt misalignment and excessive wear, which are not only costly in terms of repairs but can also pose safety hazards. This makes choosing the right roller essential for maintaining not only operational efficiency but also workplace safety. The trust in these components is often evidenced by the long-term partnerships between renowned roller manufacturers and large-scale industrial players. In the realm of return rollers, product specialization caters to diverse industrial needs. For instance, industries involved in handling bulk materials like coal or minerals may opt for impact-resistant rollers to better handle the stresses of high-volume, high-speed conveyor operations. Conversely, industries dealing with delicate or light goods may prioritize rollers that provide smoother transit to prevent product damage. Ultimately, the role of return rollers extends beyond their mechanical function. They embody the convergence of engineering prowess, user experience, and industry trust, making them pivotal in the operational stability of conveyor systems. Investing in high-quality return rollers not only supports immediate operational needs but also contributes to the longevity and reliability of industrial infrastructure, ensuring a continuous and efficient flow of business activities. As industries continue to innovate, the evolution of return roller technology will undoubtedly keep pace, constantly improving to meet the ever-growing demands of efficiency and reliability in the industrial sector.

Trustworthiness of return rollers is further augmented by their role in maintaining the structural integrity of conveyor systems. A reliable return roller can prevent issues such as conveyor belt misalignment and excessive wear, which are not only costly in terms of repairs but can also pose safety hazards. This makes choosing the right roller essential for maintaining not only operational efficiency but also workplace safety. The trust in these components is often evidenced by the long-term partnerships between renowned roller manufacturers and large-scale industrial players. In the realm of return rollers, product specialization caters to diverse industrial needs. For instance, industries involved in handling bulk materials like coal or minerals may opt for impact-resistant rollers to better handle the stresses of high-volume, high-speed conveyor operations. Conversely, industries dealing with delicate or light goods may prioritize rollers that provide smoother transit to prevent product damage. Ultimately, the role of return rollers extends beyond their mechanical function. They embody the convergence of engineering prowess, user experience, and industry trust, making them pivotal in the operational stability of conveyor systems. Investing in high-quality return rollers not only supports immediate operational needs but also contributes to the longevity and reliability of industrial infrastructure, ensuring a continuous and efficient flow of business activities. As industries continue to innovate, the evolution of return roller technology will undoubtedly keep pace, constantly improving to meet the ever-growing demands of efficiency and reliability in the industrial sector.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS