Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu pu roller

Understanding PU Rollers A Versatile Solution for Various Industries

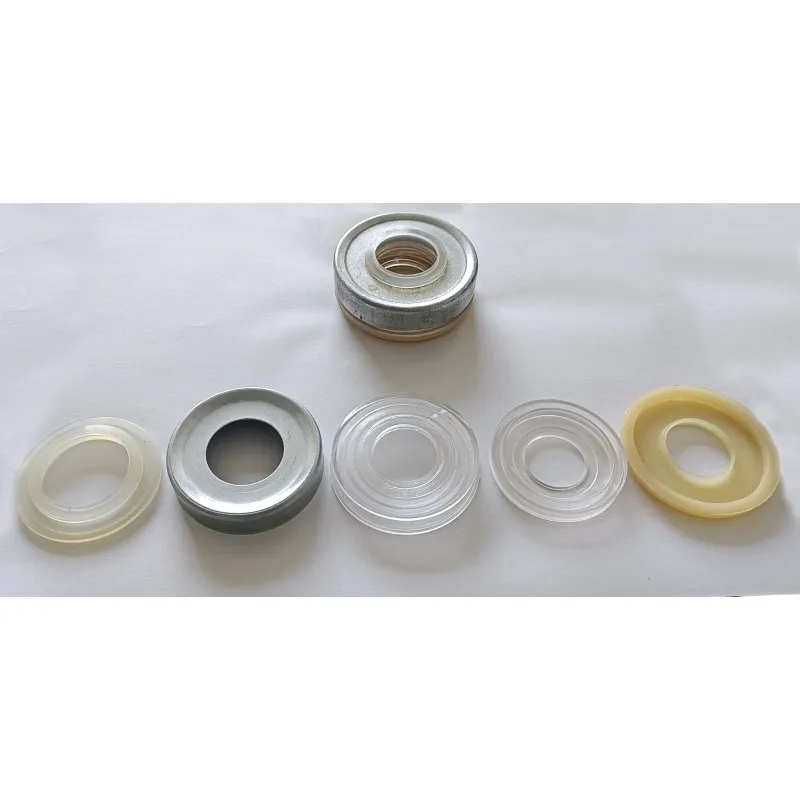

Polyurethane (PU) rollers, also known as PU covered rollers, are essential components in numerous industries due to their durability, flexibility, and resistance to wear and tear. These rollers are made by coating a core material, often steel or aluminum, with a thick layer of polyurethane, providing enhanced performance and longevity compared to traditional rubber rollers. This article will delve into the advantages, applications, and selection criteria for PU rollers.

Advantages of PU Rollers

1. Durability PU rollers are highly resistant to abrasion, making them ideal for applications where wear and tear are frequent. The hardness of the polyurethane can be tailored to meet specific needs, allowing for better performance in heavy-duty environments.

2. Chemical Resistance Polyurethane is less susceptible to degradation from various chemicals compared to rubber. This property makes PU rollers suitable for use in industries such as food processing, where contact with oils and cleaning agents is common.

3. Temperature Resistance PU can withstand a wider temperature range than many other materials. This capability ensures effective operation in environments prone to elevated temperatures, such as manufacturing plants or warehouses.

4. Reduced Noise The elasticity of polyurethane allows for quieter operation during machinery cycles. This characteristic is particularly beneficial in settings where noise reduction is necessary.

5. Versatility PU rollers are customizable in terms of size, hardness, and profile, making them adaptable to different applications across industries.

Applications

PU rollers find use in a variety of sectors, highlighting their versatility

- Manufacturing In conveyor systems, PU rollers facilitate the smooth movement of products, thanks to their low-friction surface. They are commonly employed in assembly lines, packaging machines, and material handling equipment.

- Textiles In the textile industry, PU rollers are used in processes such as printing and dyeing. Their ability to handle delicate materials without causing damage is a significant advantage in this sector.

pu roller

- Food Processing With their chemical resistance and easy cleaning properties, PU rollers are frequently used in food processing equipment, ensuring that products maintain high hygiene standards.

- Printing In printing presses, PU rollers provide consistent pressure and reduce slippage, contributing to high-quality print results.

Selection Criteria

When choosing PU rollers, there are several important factors to consider

1. Load Capacity Assess the weight that the roller will need to support. Overloading can lead to premature failure, so it's crucial to select a roller with an appropriate load capacity.

2. Hardness The hardness of the polyurethane can significantly influence performance. Softer rollers may provide better grip, while harder rollers can withstand heavier loads and resist wear.

3. Diameter and Length Depending on the application, the diameter and length of the roller will vary. It's essential to align these dimensions with the specific needs of the machinery.

4. Environmental Conditions Consider factors such as temperature extremes and exposure to harsh chemicals. Selecting the appropriate PU formulation can help ensure the longevity and effectiveness of the roller.

5. Maintenance Regular maintenance can extend the life of PU rollers. Evaluate how easy it is to clean and maintain the rollers, as this can impact operational efficiency.

Conclusion

PU rollers are a crucial component for many industrial applications, providing an excellent combination of durability, flexibility, and resistance to various environmental factors. Their adaptability to different applications makes them a preferred choice across multiple industries. By understanding their advantages and features, businesses can select the right PU rollers to optimize their operations and enhance productivity.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025