Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Februari . 19, 2025 09:06

Back to list

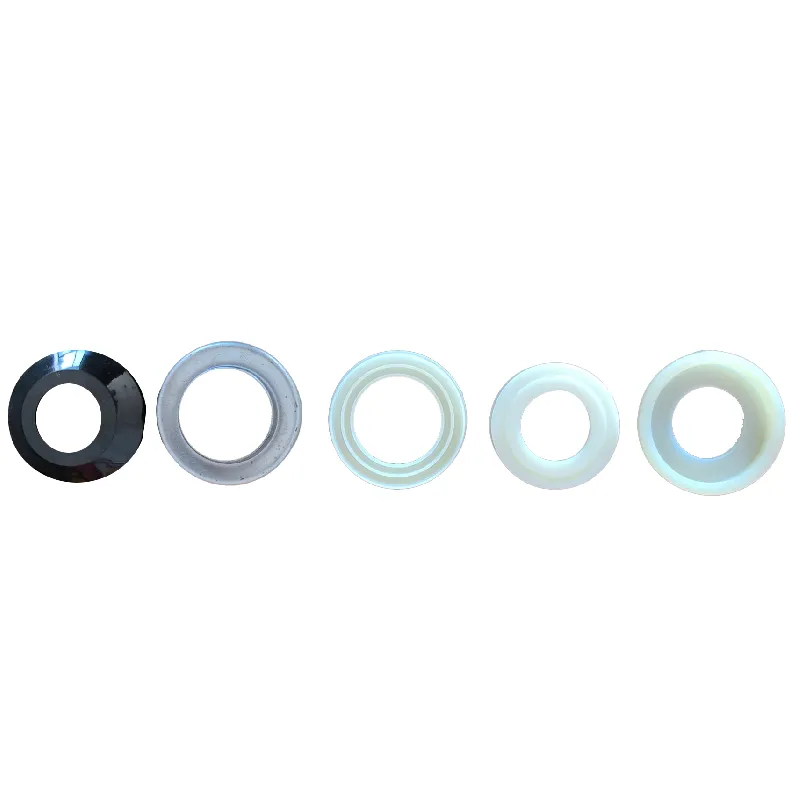

Rubber Lagging Pulley

Pulley Rubber Revolutionizing Modern Machinery

In terms of sustainability, pulley rubber contributes a significant advantage. As industries pivot towards eco-friendly practices, the production and recycling processes of rubber have been optimized to minimize environmental impact. Advances in material science have facilitated the development of recyclable rubber compounds, reducing waste and reinforcing the material's role in a sustainable future. Additionally, when considering the economic implications, pulley rubber provides a cost-effective alternative compared to traditional materials. Its longevity and low maintenance requirements result in reduced operational costs over time. This economic efficiency, paired with high performance, makes it an attractive option for budget-conscious operations aiming to maximize return on investment. Real-world testimonials underscore the efficacy of pulley rubber. In automotive applications, vehicle manufacturers report enhanced performance in drive belts and timing chains, attributing fewer breakdowns and improved fuel efficiency to the material's properties. Similarly, in conveyor system applications, companies acknowledge the reduced need for frequent replacements, citing pulley rubber’s role in enhancing operational continuity and safety. Trustworthiness and authority in the marketplace are solidified through rigorous testing and quality assurance practices that underscore the reliability of pulley rubber. Manufacturers adhere to international standards and certifications, reinforcing customer confidence in product performance. This commitment to excellence reflects in the consistent delivery of high-quality products that meet or exceed industry expectations. In conclusion, pulley rubber stands as a transformative material in the realm of modern machinery. Its blend of durability, adaptability, and environmental consideration positions it as a leader in material innovation. Industries reliant on mechanical operations continue to benefit from its unique characteristics, driving forward efficiency and sustainability in technology and production processes. As a testament to engineering innovation, pulley rubber not only addresses current challenges but also paves the way for future advancements in mechanical applications.

In terms of sustainability, pulley rubber contributes a significant advantage. As industries pivot towards eco-friendly practices, the production and recycling processes of rubber have been optimized to minimize environmental impact. Advances in material science have facilitated the development of recyclable rubber compounds, reducing waste and reinforcing the material's role in a sustainable future. Additionally, when considering the economic implications, pulley rubber provides a cost-effective alternative compared to traditional materials. Its longevity and low maintenance requirements result in reduced operational costs over time. This economic efficiency, paired with high performance, makes it an attractive option for budget-conscious operations aiming to maximize return on investment. Real-world testimonials underscore the efficacy of pulley rubber. In automotive applications, vehicle manufacturers report enhanced performance in drive belts and timing chains, attributing fewer breakdowns and improved fuel efficiency to the material's properties. Similarly, in conveyor system applications, companies acknowledge the reduced need for frequent replacements, citing pulley rubber’s role in enhancing operational continuity and safety. Trustworthiness and authority in the marketplace are solidified through rigorous testing and quality assurance practices that underscore the reliability of pulley rubber. Manufacturers adhere to international standards and certifications, reinforcing customer confidence in product performance. This commitment to excellence reflects in the consistent delivery of high-quality products that meet or exceed industry expectations. In conclusion, pulley rubber stands as a transformative material in the realm of modern machinery. Its blend of durability, adaptability, and environmental consideration positions it as a leader in material innovation. Industries reliant on mechanical operations continue to benefit from its unique characteristics, driving forward efficiency and sustainability in technology and production processes. As a testament to engineering innovation, pulley rubber not only addresses current challenges but also paves the way for future advancements in mechanical applications.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS