Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu idlers and rollers

Idlers and Rollers The Unsung Heroes of Machinery

In the world of machinery and industrial engineering, the significance of idlers and rollers often goes unnoticed. Yet, these simple yet crucial components play a vital role in various applications, ensuring efficiency and smooth operation across countless systems. From conveyor belts to construction equipment, understanding the functions and benefits of idlers and rollers can shed light on their importance in modern industry.

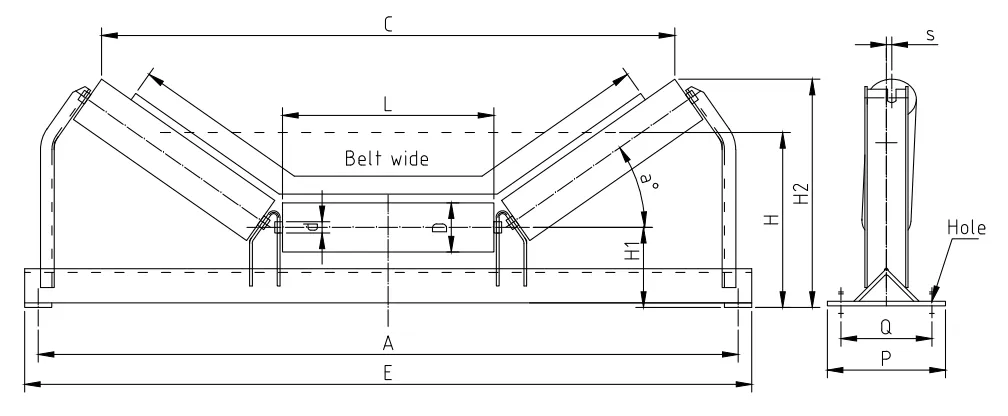

Idlers are defined as rotating components that support a belt or chain within conveyor systems. They do not contribute to the actual propulsion of the material being transported but are essential for maintaining tension and alignment. By supporting the belt, idlers help to minimize wear and tear, thereby extending the lifespan of the conveyor system. This support also prevents slippage, which can lead to downtime and increased operational costs.

On the other hand, rollers serve a similar purpose but often come into play in different contexts. These cylindrical components enable smooth movement across surfaces, reducing friction as materials are moved from one point to another. Rollers are found in various applications, such as in roller coasters, gym equipment, and heavy machinery. Their ability to decrease friction and support heavy loads makes them indispensable in sectors ranging from manufacturing to entertainment.

idlers and rollers

One of the most significant benefits of idlers and rollers is their contribution to energy efficiency. By minimizing friction and optimizing movement, these components allow machines to operate more smoothly, requiring less energy to perform the same task. This energy efficiency not only contributes to lower operational costs but also aligns with the growing emphasis on sustainability in industrial practices. Companies that utilize efficient machinery can significantly reduce their carbon footprint, contributing positively to environmental preservation.

Moreover, the technological advancements in the design and manufacture of idlers and rollers have enhanced their performance and durability. With innovations such as self-lubricating materials and advanced seal designs, modern idlers and rollers are more reliable than ever. These improvements reduce maintenance requirements and downtime, allowing businesses to focus on productivity rather than repair and replacement.

Additionally, the versatility of idlers and rollers makes them suitable for a wide array of applications. In the mining industry, for example, they are fundamental in conveyor systems that transport ores and minerals over long distances. In agriculture, they facilitate the movement of harvested crops from the field to processing facilities. The versatility of these components means that they adapt well to various environmental conditions, ensuring consistent performance across different sectors.

In conclusion, while idlers and rollers may not be the most glamorous components of machinery, their role in enhancing efficiency and operational effectiveness cannot be overstated. As industries continue to evolve and prioritize sustainable practices, the importance of these unsung heroes will only grow. By investing in high-quality idlers and rollers, companies not only enhance their machinery's performance but also contribute to a more sustainable future. Thus, acknowledging the importance of these components is essential for any business looking to optimize its operations and contribute positively to the environment.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025