Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu feeder idler

Understanding Feeder Idlers Key Components in Material Handling

In the realm of material handling and processing, feeder idlers play a crucial role in ensuring smooth and efficient operations. These devices are often overlooked but are essential in a wide array of industries, including mining, manufacturing, and construction. This article delves into the functional significance of feeder idlers, their designs, and how they contribute to improved productivity and operational efficiency.

What are Feeder Idlers?

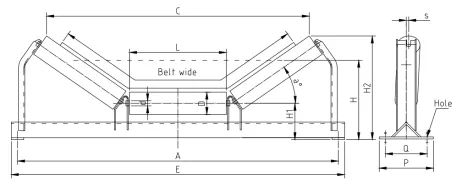

Feeder idlers are cylindrical rollers that support and guide conveyor belts, specifically in applications where materials need to be fed into a system in a controlled manner. They are critical in maintaining the alignment and tension of the belt, which is vital for the efficient movement of materials from one point to another. By ensuring a continuous flow of materials, feeder idlers minimize downtime and enhance the overall throughput of operations.

The Role of Feeder Idlers in Conveyor Systems

Feeder idlers serve several key functions in conveyor systems

1. Material Division and Regulation In many industrial processes, materials must be handled carefully to maintain the integrity of both the product and the equipment. Feeder idlers help regulate the flow of materials onto the conveyor belt, preventing clogs and ensuring that the right amount of product is delivered to subsequent processing stages.

2. Prevention of Slippage Modern feeder idlers are engineered to reduce slippage, which can lead to uneven wear on the conveyor system. By maintaining belt tension and alignment, they contribute to more predictable and reliable materials handling.

3. Support System The structural support provided by feeder idlers is essential in maintaining the longevity of conveyor systems. They assist in distributing the weight of heavy materials evenly across the conveyor, thus preventing premature wear and tear.

4. Vibration Reduction A well-designed feeder idler can absorb and dampen vibrations from the material being loaded onto the conveyor belt. This function helps protect both the belt and the equipment and enhances the overall operational stability of the material handling system.

feeder idler

Design Variations and Their Applications

Feeder idlers come in various designs tailored to meet specific requirements. The choice of design often depends on factors such as the type of material being handled, the speed of the conveyor, and the operating environment. Common types of feeder idlers include

- Trough Idlers These are widely used in bulk material handling applications where they support conveyor belts that transport materials in a 'trough' shape.

- Return Idlers Positioned on the return side of the conveyor belt, these idlers guide the belt back to the loading point and maintain tension.

- Impact Idlers Designed to absorb the energy of falling materials, these idlers protect the conveyor system and ensure a smooth transition of materials into the belt.

Importance of Regular Maintenance

Despite their robust design, feeder idlers require regular maintenance to ensure optimal performance. Lubrication of bearings, checking for wear and tear, and alignment adjustments are critical to preventing breakdowns. Neglecting maintenance can lead to slippage, misalignment, and ultimately, costly downtimes.

Conclusion

Feeder idlers, though relatively simple in design, are vital components in a variety of material handling systems. They play a significant role in the efficiency and reliability of conveyor operations. Understanding their functions and implementing proper maintenance strategies can result in enhanced productivity and reduced operational costs. Whether in a manufacturing plant or a mining site, ensuring the optimal performance of feeder idlers is essential to the smooth flow of materials and the overall success of industrial operations. By investing in quality idlers and regular upkeep, businesses can achieve greater efficiency and reliability in their material handling processes.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025