Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Januari . 26, 2025 01:44

Back to list

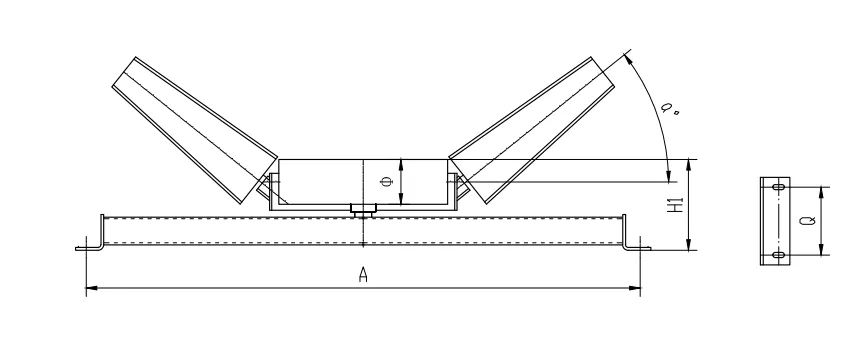

Troughing Roller

In the world of material handling, efficiency and reliability are of utmost importance. Conveyor roller brackets, though often overlooked, play a critical role in ensuring the seamless operation of conveyor systems. Understanding the intricacies of these components can greatly enhance the functionality of your material handling apparatus.

Authority and reliability in the field also stem from adherence to industry standards and certifications. Conveyor roller brackets must comply with established benchmarks such as ISO standards to assure users of their quality, safety, and performance. Trusted manufacturers and suppliers often undergo rigorous testing procedures and quality checks to guarantee that their products perform under every operational condition. Real-world experience resonates with the truth that installation and maintenance are as crucial as selection. Proper installation techniques ensure that the brackets support the conveyor rollers without any misalignments, which could lead to premature wear or system failure. Similarly, regular maintenance and inspections can anticipate potential issues, such as metal fatigue or loosened fastenings, before they result in costly downtimes or safety hazards. It is always advisable to have experienced technicians conduct installation and routine checks, providing peace of mind and operational efficiency. Incorporating conveyor roller brackets into smart systems represents a future-forward approach, blending traditional engineering with modern technology. Implementing smart sensors and automated monitoring can provide real-time data on the functionality of these components, identifying potential weak points before they become critical issues. This advancement not only ensures reliability but also optimizes operational efficiency, reducing maintenance costs and prolonging the lifespan of the entire conveyor system. Trustworthiness in the realm of conveyor components also speaks to the sustainability of chosen solutions. Selecting durable, high-quality materials reduces the need for frequent replacements, thus minimizing operational disruptions and promoting environmentally friendly practices. Opting for suppliers committed to sustainable practices, such as recycling and responsible sourcing of materials, further reinforces the ethical considerations manufacturers and distributors must adopt. In conclusion, conveyor roller brackets, despite their simplicity, are indispensable in the efficient operation of conveyor systems. They must be chosen, installed, and maintained with expertise, authority, and foresight to extend the life of conveyor systems, optimize operations, and ensure safety. The added consideration for smart technology integration and sustainability demonstrates a forward-thinking approach that secures reliability and efficiency in material handling for the future.

Authority and reliability in the field also stem from adherence to industry standards and certifications. Conveyor roller brackets must comply with established benchmarks such as ISO standards to assure users of their quality, safety, and performance. Trusted manufacturers and suppliers often undergo rigorous testing procedures and quality checks to guarantee that their products perform under every operational condition. Real-world experience resonates with the truth that installation and maintenance are as crucial as selection. Proper installation techniques ensure that the brackets support the conveyor rollers without any misalignments, which could lead to premature wear or system failure. Similarly, regular maintenance and inspections can anticipate potential issues, such as metal fatigue or loosened fastenings, before they result in costly downtimes or safety hazards. It is always advisable to have experienced technicians conduct installation and routine checks, providing peace of mind and operational efficiency. Incorporating conveyor roller brackets into smart systems represents a future-forward approach, blending traditional engineering with modern technology. Implementing smart sensors and automated monitoring can provide real-time data on the functionality of these components, identifying potential weak points before they become critical issues. This advancement not only ensures reliability but also optimizes operational efficiency, reducing maintenance costs and prolonging the lifespan of the entire conveyor system. Trustworthiness in the realm of conveyor components also speaks to the sustainability of chosen solutions. Selecting durable, high-quality materials reduces the need for frequent replacements, thus minimizing operational disruptions and promoting environmentally friendly practices. Opting for suppliers committed to sustainable practices, such as recycling and responsible sourcing of materials, further reinforces the ethical considerations manufacturers and distributors must adopt. In conclusion, conveyor roller brackets, despite their simplicity, are indispensable in the efficient operation of conveyor systems. They must be chosen, installed, and maintained with expertise, authority, and foresight to extend the life of conveyor systems, optimize operations, and ensure safety. The added consideration for smart technology integration and sustainability demonstrates a forward-thinking approach that secures reliability and efficiency in material handling for the future.

Next:

Latest news

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025

OUR PRODUCTS