Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

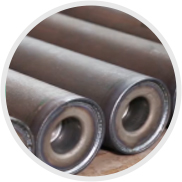

Zulu conveyor pulley types

Understanding Conveyor Pulley Types

Conveyor systems are integral to various industries, facilitating the efficient movement of materials and goods. At the heart of these systems lies the conveyor pulley, a critical component that helps drive and redirect the conveyor belt. Understanding the different types of conveyor pulleys is essential for selecting the right configuration for specific applications, ensuring optimal performance and longevity of the system.

1. Drive Pulley

The drive pulley, often referred to as a motorized pulley, is a primary component in conveyor systems. It is responsible for moving the belt and is typically located at the loading end of the conveyor. This type of pulley is made from sturdy materials designed to withstand high torque and stresses. Drive pulleys can come with different surface textures, including smooth or rubberized finishes, depending on the specific requirements of the application. They are often equipped with a drive mechanism, such as a geared motor, to ensure consistent operation and drive the belt efficiently.

2. Idler Pulley

Idler pulleys are non-powered pulleys used to support and guide the conveyor belt. They are critical for maintaining belt tension and alignment, ensuring smooth operation throughout the system. Idler pulleys can vary in size and shape, with standard configurations including flat, troughing, and impact idlers. Flat idlers are typically used in simpler conveyor configurations, while troughing idlers are designed to support bulk materials, providing additional stability and minimizing spillage. Impact idlers are specifically designed to absorb the impact of heavy loads, protecting the belt and extending its life.

Return pulleys are located at the end of the conveyor system and are specifically designed to maintain belt tension as the material is transported back to the loading point. These pulleys have a vital role in ensuring that the conveyor belt remains properly positioned and that there is minimal wear and tear on the belt itself. Like idler pulleys, return pulleys are typically unpowered and work in conjunction with other pulleys to facilitate the continuous movement of the belt.

conveyor pulley types

4. Snub Pulley

A snub pulley is designed to increase the angle of wrap between the belt and the drive pulley, ensuring better grip and reducing slippage during operation. This pulley is often used in conjunction with the drive pulley to enhance the overall performance of the system, especially in high-tension applications. Snub pulleys can also be useful for redirecting the belt or providing additional support, improving the system's efficiency.

5. Take-Up Pulley

Take-up pulleys are used to adjust and maintain the tension of the conveyor belt. These pulleys are critical for ensuring that the belt operates smoothly and does not slip during operation. Take-up systems come in two main types manual and automatic. Manual take-up systems allow for manual adjustments, while automatic systems use tension sensors to dynamically adjust the belt tension, making them ideal for applications with varying loads.

6. Split Pulley

Split pulleys are engineered for easier maintenance and replacement. This unique design allows users to disassemble the pulley without removing the entire conveyor system, saving time and minimizing downtime. Split pulleys can be configured as drive or idler pulleys, offering flexibility in design and suitability for various materials and environments.

Conclusion

Selecting the appropriate type of conveyor pulley is crucial for ensuring a reliable, efficient, and cost-effective conveyor system. By understanding the specific roles and characteristics of drive, idler, return, snub, take-up, and split pulleys, operators can optimize their conveyor designs for particular materials and applications. Proper selection and maintenance of these pulleys not only enhance system performance but also extend the lifespan of the conveyor belt, leading to significant cost savings in the long run. As industries continue to evolve, so will the technology and innovations surrounding conveyor pulleys, ensuring their relevance and necessity in modern material handling processes.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025