Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor idler roller design

Conveyor Idler Roller Design Key Considerations and Principles

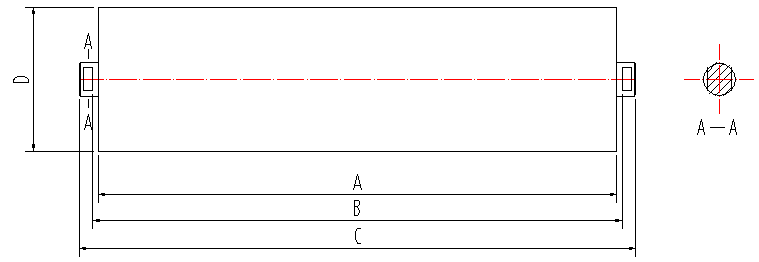

Conveyor systems are integral to many industries, facilitating the efficient movement of materials from one location to another. Among the various components that make up these systems, the conveyor idler roller plays a crucial role in maintaining the efficiency and reliability of material transport. This article will explore the essential aspects of conveyor idler roller design, emphasizing its significance, types, and engineering considerations.

Importance of Conveyor Idler Rollers

Conveyor idler rollers support the conveyor belt and play a pivotal role in ensuring smooth operation. They reduce the friction between the belt and the conveyance system and help in maintaining the correct alignment of the belt. Moreover, properly designed idler rollers minimize wear on the belt, extend its lifespan, and improve energy efficiency by reducing rolling resistance. Ultimately, the design of these rollers impacts the overall performance of the conveyor system and the cost of operations.

Types of Conveyor Idler Rollers

There are several types of conveyor idler rollers, each designed for specific applications

1. Flat Idler Rollers These are the most common type used in standard belt conveyors, providing a flat surface for belt support.

2. Trough Idler Rollers Designed with a slight angle, these rollers support the belt in a trough shape, allowing for the effective transport of bulk materials.

4. Self-Aligning Idler Rollers These rollers minimize belt distortion and ensure the proper tracking of the conveyor belt, which is essential for maintaining operational efficiency.

conveyor idler roller design

5. Return Idler Rollers Positioned on the return side of the conveyor belt, they support the belt as it returns to the loading point, thereby ensuring that the system remains balanced.

Engineering Considerations in Idler Roller Design

Designing effective conveyor idler rollers requires a comprehensive understanding of various engineering principles. Key considerations include

1. Material Selection The choice of materials for idler rollers is critical. Commonly used materials include steel, polyethylene, and rubber. The selected material should offer high strength, resistance to wear, and durability under environmental stressors.

2. Roller Diameter and Width The diameter and width of the roller significantly influence the carrying capacity and the friction of the system. Larger diameters generally reduce rolling resistance, while wider rollers can carry more material.

3. Bearing Configuration Properly designed bearing systems are necessary for minimizing friction and prolonging the lifespan of the rollers. Bearings must be selected based on load requirements and speed of operation.

4. Sealing and Protection Idler rollers should be sealed adequately to prevent contaminants like dust and moisture from entering the bearing housing. Effective sealing ensures longevity and operational reliability.

5. Maintenance and Accessibility A well-designed idler roller system should allow for easy maintenance and inspection. Consideration of access points will facilitate timely interventions, reducing downtime and operational costs.

Conclusion

In conclusion, the design of conveyor idler rollers is a critical aspect of overall conveyor system efficiency and reliability. By considering the types of rollers, material selection, engineering principles, and maintenance accessibility, engineers can create idler roller systems that optimize operations across diverse industrial applications. As technology advances, newer design methodologies and materials will undoubtedly continue to enhance the performance and lifespan of conveyor idler rollers, further supporting the growing demands of modern industry.

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025