Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Conveyor System Head Roller Design and Functionality Overview

Understanding the Conveyor Head Roller Essential Component of Material Handling Systems

In the realm of material handling and transportation systems, conveyor belts serve as the backbone for efficient movement of goods. Among the key components of these systems is the conveyor head roller, an often-overlooked element that plays a crucial role in the overall functionality and efficiency of conveyor systems.

What is a Conveyor Head Roller?

The conveyor head roller, also known as the drive roller, is situated at the discharge end of a conveyor belt. Its primary function is to facilitate the movement of the belt by providing the necessary drive mechanism. The head roller is typically powered by an electric motor, either directly or via a series of belts and pulleys, which translates electrical energy into rotational motion. As the roller spins, it drives the conveyor belt forward, enabling the transportation of materials across various distances, from a few feet to several miles depending on the application.

Importance of the Conveyor Head Roller

1. Drive Mechanism As the primary driving force behind the conveyor belt system, the head roller ensures that the belt moves smoothly and consistently. Its effective functioning is vital for maintaining operational efficiency and preventing disruptions in material flow.

2. Load Bearing The head roller must be designed to handle significant loads, depending on the type of materials being transported. It must cope with not only the weight of the goods but also the stresses incurred during startup and operation. Robust construction and durability are essential for ensuring the longevity and reliability of the conveyor system.

3. Alignment and Guidance Proper alignment of the conveyor belt is crucial for avoiding misalignment and slippage during operation. The head roller plays a role in guiding the belt along the intended path. Features such as crowned surfaces or guides can enhance belt tracking, reducing wear and tear.

4. Transfer Points In conveyor systems with multiple belts or transfer points, head rollers can help in the seamless transition of materials from one segment to another. This is essential in applications where materials are moved between different conveyor lines or machinery.

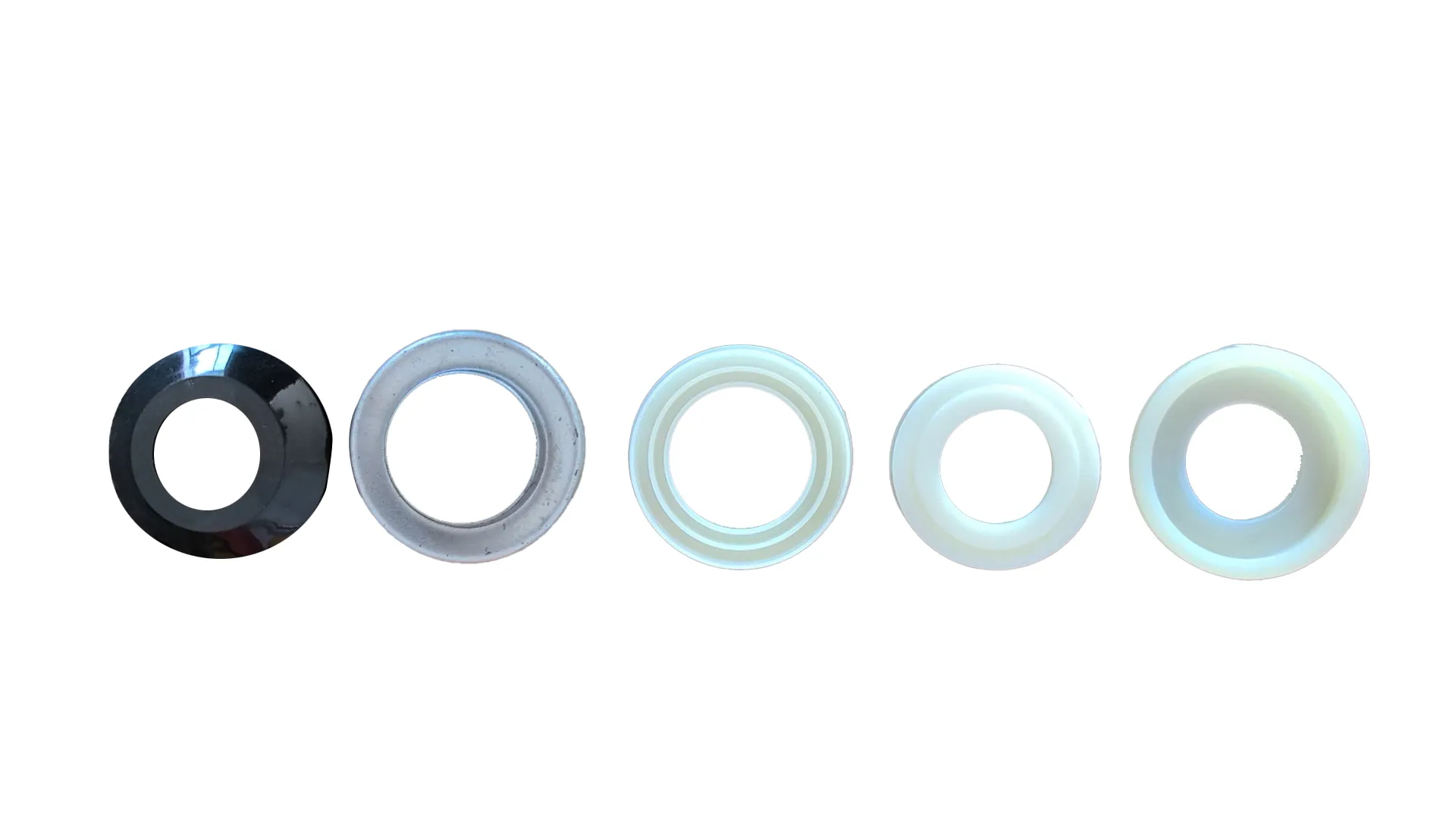

Types of Conveyor Head Rollers

conveyor head roller

Conveyor head rollers come in various designs and configurations, tailored to meet the specific requirements of different applications

. The main types include1. Rubber-Coated Rollers These rollers are often used in applications where grip is essential to prevent slippage, particularly when dealing with heavier loads or incline belts.

2. Crowned Rollers Featuring a slight curvature on the surface, crowned rollers aid in tracking and alignment of the conveyor belt, minimizing the chances of lateral movement.

3. Solid Rollers Made from durable materials like steel, these rollers are designed for heavy-duty applications and can withstand significant stress, making them suitable for tough industrial environments.

4. Lightweight Plastic Rollers Used in smaller conveyors or applications requiring less load capacity, these rollers are lighter and often more economical while still providing adequate performance.

Maintenance of Conveyor Head Rollers

To ensure optimal functionality, regular maintenance of conveyor head rollers is essential. Operators should conduct routine inspections to check for signs of wear, misalignment, or damage. Lubrication of the bearings and ensuring proper tension in the drive system can help prevent failures. Additionally, cleaning the rollers and surrounding areas can help reduce debris buildup, which might interfere with performance.

Conclusion

The conveyor head roller, although small in comparison to the entire system, is a vital component of conveyor belt operations. Its role in driving the belt, bearing loads, and ensuring proper alignment cannot be overstated. In the context of industrial efficiency and reliability, understanding the significance of the head roller and maintaining its performance can lead to smoother operations and reduced downtime. Companies relying on conveyor systems should prioritize the selection and maintenance of their head rollers, recognizing them as integral to their material handling processes. With the right attention and care, these components can significantly enhance productivity and operational success.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025