Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor belt roll

The Essential Role of Conveyor Belt Rolls in Modern Industry

In the dynamic landscape of modern industrial operations, efficiency and productivity are paramount. Central to achieving these goals is the conveyor belt, a vital component in various sectors ranging from manufacturing to logistics. At the heart of any effective conveyor system lies the conveyor belt roll, a crucial element that significantly influences the performance and reliability of the entire setup.

Understanding Conveyor Belt Rolls

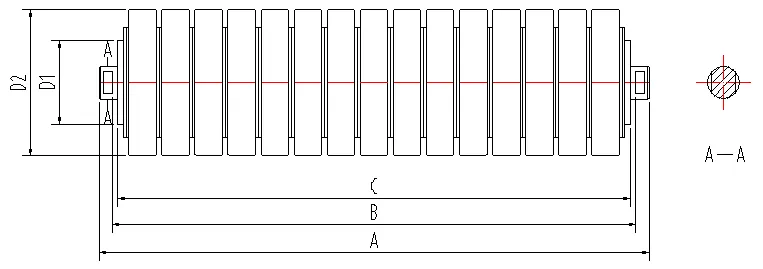

A conveyor belt roll consists of a continuous loop of material that is designed to transport goods from one point to another. This roll is typically made from durable materials such as rubber, plastic, or metal, allowing it to withstand the demands of heavy loads and constant use. The design of the belt can vary greatly depending on the specific application, accommodating various shapes, sizes, and weights of materials being transported.

The mechanism that drives the conveyor belt roll usually includes a series of pulleys and rollers. The belt is anchored to these components, which allow it to move smoothly and efficiently along a predetermined path. This system minimizes friction and wear, extending the lifespan of the conveyor belt and ensuring that it operates effectively over time.

Applications in Various Industries

Conveyor belt rolls are utilized across a wide array of industries. In manufacturing, they transport raw materials to assembly lines, facilitating streamlined production processes. In warehouses and distribution centers, conveyor systems help manage inventory by moving products quickly from storage to shipping areas. Similarly, in the food industry, conveyor belts play a critical role in the processing and packaging of goods, adhering to stringent hygiene and safety standards.

One prominent application is in mining and quarrying, where conveyor belts are essential for moving large volumes of extracted materials, such as coal, minerals, or gravel. The robust nature of these belts enables them to handle abrasive substances over long distances, thereby reducing labor costs and enhancing operational efficiency.

Benefits of Conveyor Belt Rolls

conveyor belt roll

The integration of conveyor belt rolls into industrial operations comes with numerous benefits. One of the most significant advantages is increased efficiency. Conveyor systems streamline the movement of materials, reducing the time and labor required for manual handling. This efficiency not only accelerates production rates but also minimizes the risk of human error and potential workplace injuries.

Another noteworthy benefit is flexibility. Conveyor belt rolls can be designed and configured to meet specific operational requirements. Whether it involves creating inclined, horizontal, or curved paths, the adaptability of conveyor systems allows businesses to optimize their layouts for maximum throughput.

Moreover, the durability of modern conveyor belt materials ensures that they can withstand harsh working conditions, including extreme temperatures, chemical exposure, and heavy loads. This resilience leads to lower maintenance costs and less frequent replacements, ultimately contributing to a more cost-effective operation.

Innovations in Conveyor Belt Technology

As industries continue to evolve, so do the technologies surrounding conveyor belt rolls. Innovations in materials science have led to the development of composite belts that combine the best features of rubber and synthetic materials, offering enhanced strength and flexibility. Smart technologies, such as IoT-enabled sensors, are now being integrated into conveyor systems, allowing for real-time monitoring and predictive maintenance. This proactive approach minimizes downtime and optimizes overall system performance.

Additionally, advancements in automation and robotics are transforming how conveyor belts are used. Automated guided vehicles (AGVs) and robotic arms can work in conjunction with conveyor systems to create seamless workflows, further enhancing productivity and operational efficiency.

Conclusion

In conclusion, conveyor belt rolls play an essential role in the functionality and efficiency of numerous industries. By facilitating the smooth movement of materials, they contribute significantly to productivity and safety in the workplace. As technology advances, the capabilities of conveyor systems will likely expand, providing even more innovative solutions to meet the ever-growing demands of modern industrial operations. Embracing these developments will be crucial for companies looking to maintain a competitive edge in today's fast-paced market.

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025