Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor drum

The Importance of Conveyor Drums in Industrial Operations

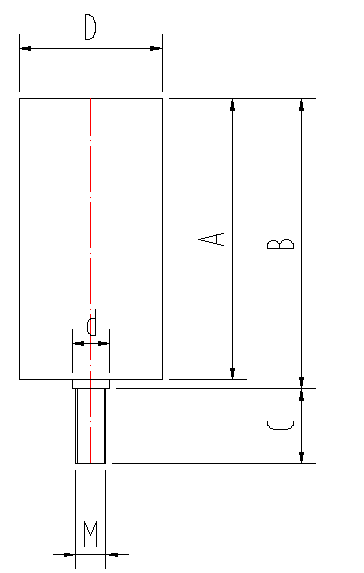

Conveyor systems play a pivotal role in various industrial sectors, facilitating the efficient movement of materials over short or long distances. At the heart of these systems lies a crucial component known as the conveyor drum. Conveyor drums, also referred to as pulleys, are cylindrical devices that help in driving the belt of a conveyor system, ensuring smooth and continuous operation.

The primary function of a conveyor drum is to provide the necessary tension and support for the conveyor belt. They work in conjunction with other components such as idlers, rollers, and the belt itself, forming a cohesive unit that aids in transporting goods. The drums are typically placed at both the beginning and the end of the conveyor system, with one drum serving as the drive pulley and the other as the tail pulley.

The design and materials used in manufacturing conveyor drums are critical to their performance and longevity

. Commonly made from steel, aluminum, or rubber, these materials are selected based on factors such as load capacity, environmental conditions, and specific application requirements. For instance, rubber-coated drums offer better grip and reduce slippage, making them ideal for steep inclines or heavy loads. In contrast, steel drums are favored for their strength and durability in harsh environments.conveyor drum

One of the key considerations in the design of conveyor drums is their ability to withstand wear and tear. As the conveyor belt moves, it creates friction against the drum surface, which can lead to degradation over time. Therefore, it is essential to employ high-quality materials and innovative engineering solutions to enhance the lifespan of these components. Regular maintenance, including inspections and timely replacements, can also help prolong the life of conveyor drums and ensure optimal system performance.

Another significant aspect of conveyor drums is their role in enhancing energy efficiency. Properly aligned and calibrated drums minimize friction and energy consumption, allowing the conveyor system to operate smoothly without unnecessary power expenditure. Additionally, well-maintained drums contribute to reduced operational costs by limiting wear on the conveyor belt itself, resulting in fewer replacements and downtime.

In conclusion, conveyor drums are integral to the effective functioning of conveyor systems across various industries. Their design, material composition, and maintenance protocols are all crucial for guaranteeing reliability and efficiency. As industries continue to evolve and demand more sophisticated material handling solutions, the importance of high-quality conveyor drums will remain paramount. Investing in advanced drum technology not only enhances operational efficiency but also supports sustainable practices by reducing energy consumption and waste.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025