Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Julai . 10, 2024 20:25

Back to list

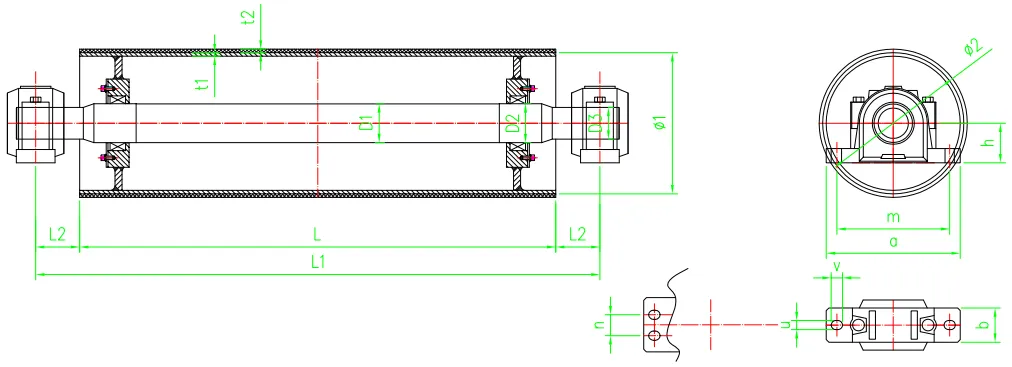

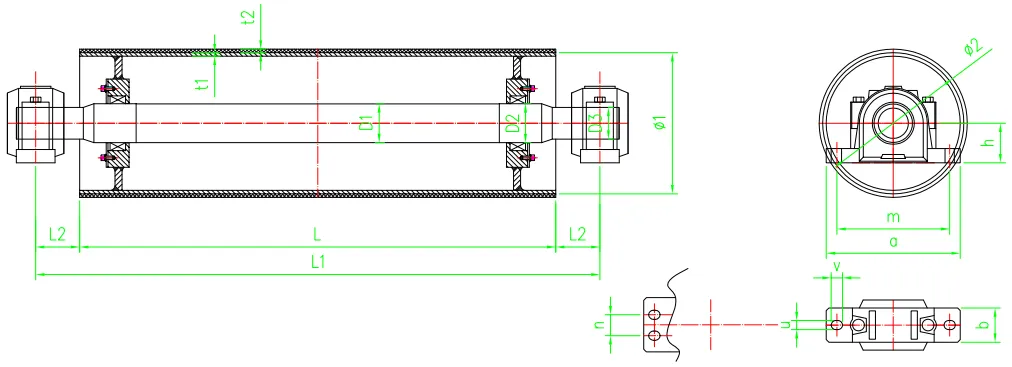

Assembly of Conveyor Rollers Step-by-Step Guide for Efficient Installation and Operation.

Conveyor Roller Assembly What You Need to Know

Conveyor roller assembly plays a crucial role in the smooth operation of conveyor systems in various industries. From manufacturing plants to distribution centers, conveyor rollers are essential components that help move products along the production line.

The conveyor roller assembly consists of several key elements that work together to ensure efficient and reliable transportation of goods. These elements include the roller tube, bearings, shaft, and housing. Let's take a closer look at each of these components

1. Roller Tube The roller tube is the main body of the conveyor roller and is typically made of materials like steel, aluminum, or plastic. The tube is responsible for supporting the weight of the products being transported and ensuring smooth movement along the conveyor system.

2. Bearings Bearings are crucial components that allow the conveyor roller to rotate smoothly. They reduce friction and enable the roller to move freely, even under heavy loads. Bearings come in various types, including ball bearings and roller bearings, and must be properly lubricated to ensure longevity and performance.

3. Shaft The shaft is the central support structure that runs through the roller tube and connects to the bearings

conveyor roller assembly. The shaft provides stability and ensures proper alignment of the roller, allowing it to spin without wobbling or getting stuck. Shafts are typically made of durable materials like steel or stainless steel to withstand the demands of continuous operation. 4. Housing The housing is the outer covering that encases the roller assembly and provides protection against dust, debris, and other contaminants. The housing also helps to maintain the alignment of the roller components and prevent them from coming loose or dislodging during operation. Proper assembly and maintenance of conveyor rollers are essential to ensure optimal performance and longevity. Regular inspection and lubrication of bearings, alignment of shafts, and cleaning of roller tubes are crucial tasks that help prevent costly downtime and repairs. It is also important to choose the right type of conveyor roller assembly for your specific application. Factors such as load capacity, conveyor speed, product size, and environmental conditions should be taken into consideration when selecting the appropriate roller components. In conclusion, conveyor roller assembly is a critical component of conveyor systems that enable the efficient movement of products in various industries. By understanding the key elements of a conveyor roller assembly and following proper maintenance practices, businesses can ensure smooth operation and maximize the lifespan of their conveyor systems.

conveyor roller assembly. The shaft provides stability and ensures proper alignment of the roller, allowing it to spin without wobbling or getting stuck. Shafts are typically made of durable materials like steel or stainless steel to withstand the demands of continuous operation. 4. Housing The housing is the outer covering that encases the roller assembly and provides protection against dust, debris, and other contaminants. The housing also helps to maintain the alignment of the roller components and prevent them from coming loose or dislodging during operation. Proper assembly and maintenance of conveyor rollers are essential to ensure optimal performance and longevity. Regular inspection and lubrication of bearings, alignment of shafts, and cleaning of roller tubes are crucial tasks that help prevent costly downtime and repairs. It is also important to choose the right type of conveyor roller assembly for your specific application. Factors such as load capacity, conveyor speed, product size, and environmental conditions should be taken into consideration when selecting the appropriate roller components. In conclusion, conveyor roller assembly is a critical component of conveyor systems that enable the efficient movement of products in various industries. By understanding the key elements of a conveyor roller assembly and following proper maintenance practices, businesses can ensure smooth operation and maximize the lifespan of their conveyor systems.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS