Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu v plow belt scraper

Understanding the Functionality and Importance of V Plow Belt Scrapers

In the realm of conveyor systems, efficient material handling is crucial for improving productivity and reducing operational costs. One critical component that plays a significant role in maintaining the effectiveness of conveyor belts is the V plow belt scraper. This device is essential for ensuring that the surface of the conveyor belt remains clean, which can significantly enhance the overall performance and longevity of the system.

What is a V Plow Belt Scraper?

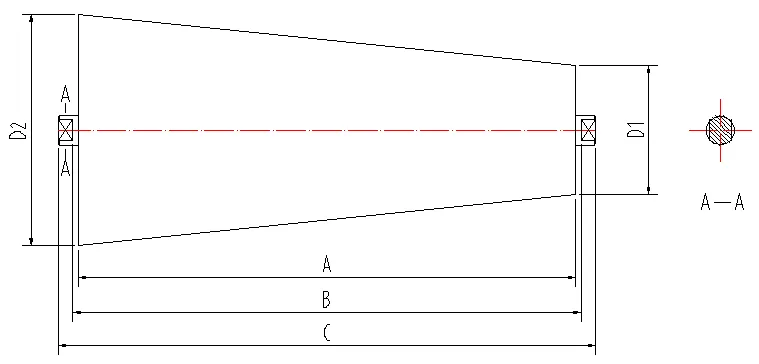

A V plow belt scraper, also known simply as a plow scraper, is a mechanical component designed to remove material that accumulates on the surface of a conveyor belt during operation. The V shape refers to the design of the blade, which is typically angled to optimize the scraping action. Positioned at an appropriate angle, this scraper can effectively dislodge and remove sticky materials, debris, and other contaminants that may hinder the smooth operation of the conveyor system.

How Does It Work?

The V plow scraper operates by leveraging gravity and the movement of the conveyor belt itself. As the belt moves, the scraper’s blade engages with the surface, effectively pushing off any adhered materials. The design of the V plow allows for efficient removal of materials without causing excessive friction or wear on the belt. By maintaining a clean belt surface, the scraper helps prevent spillage, which can lead to operational inefficiencies and increased safety risks in the workplace.

Benefits of Using V Plow Belt Scrapers

1. Increased Efficiency By keeping the conveyor belt free of obstructions, the V plow scraper helps maintain the belt's operational efficiency. This leads to reduced downtime associated with manual cleaning, allowing for a smoother workflow.

v plow belt scraper

2. Enhanced Safety A clean conveyor belt minimizes the risk of slipping hazards caused by spilled materials. This contributes to a safer working environment for employees who interact with the conveyor systems.

3. Extended Equipment Life Regular use of a V plow belt scraper can prolong the life of the conveyor belt. By preventing the accumulation of debris, the scraper helps reduce wear and tear, thereby decreasing the frequency of replacements and repairs.

4. Cost-Effectiveness While there is a cost associated with acquiring and maintaining V plow belt scrapers, the long-term savings from reduced maintenance, fewer repairs, and increased efficiency can be substantial.

Installation and Maintenance

Installing a V plow belt scraper is a straightforward process, but it is essential to ensure that it is positioned correctly to achieve optimal performance. Installation typically involves mounting the scraper on a framework adjacent to the conveyor system, adjusting it to the appropriate angle, and ensuring it is securely fastened to prevent any movement during operation.

Routine maintenance is also critical for ensuring the longevity and effectiveness of the scraper. Regular inspections should be conducted to check for wear and tear on the blades, as well as to ensure that the scraper remains aligned with the conveyor belt. Replacing worn blades promptly is necessary to maintain effective scraping action.

Conclusion

In conclusion, V plow belt scrapers are an indispensable part of many conveyor systems across various industries. They play a vital role in keeping conveyor belts clean, thereby enhancing efficiency, safety, and the lifespan of the equipment. As organizations seek to optimize their operations and minimize costs, investing in high-quality belt scrapers can yield significant returns. Ensuring proper installation and maintenance of these devices will not only improve material handling processes but also provide a safer and more productive work environment. As we continue to innovate and enhance industrial practices, the significance of these simple yet effective tools cannot be overstated.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025