Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu V-Belt Idler Pulleys Selection Guide Based on Size and Application Needs

Understanding V-Belt Idler Pulleys by Size

V-belt idler pulleys are integral components in various mechanical systems, commonly found in cars, agricultural machinery, and industrial equipment. Their primary purpose is to guide and maintain tension on the V-belts, which transmit power between different parts of machinery. V-belts are generally characterized by their trapezoidal cross-section that fits snugly into the grooves of the pulleys, enabling efficient power transfer. Understanding the role and selection of V-belt idler pulleys by size is essential for optimizing performance and longevity in various applications.

The Importance of Idler Pulleys

Idler pulleys play a crucial role in a mechanical system for several reasons. First, they help maintain the correct tension on the V-belt, ensuring that the belt remains in contact with the drive pulleys. This contact is vital for effective power transmission. Second, idler pulleys redirect the V-belt’s path to ensure that it operates smoothly, preventing slippage and reducing wear and tear. Lastly, proper alignment and sizing of idler pulleys can reduce the mechanical load on other components, prolonging the life of the entire system.

Sizing of Idler Pulleys

When selecting idler pulleys, size is one of the most critical factors to consider. The size of an idler pulley is determined by its diameter, width, and the groove profile that matches the corresponding V-belt. An appropriate size ensures maximum contact area with the belt, which is essential for effective energy transfer and minimal slippage.

1. Diameter The diameter of the idler pulley affects the belt's tension and the overall speed of rotation. Generally, a larger pulley will create less tension on the belt but may lead to increased inertia. Conversely, a smaller pulley can maintain higher tension but may lead to increased wear on the belt. Thus, selecting the right diameter is a balancing act that depends on the requirements of the specific application.

2. Width The width of the idler pulley should match the width of the V-belt being used. If the width is too narrow, the belt may displace off the pulley, leading to slippage. However, if the pulley is too wide, it can create excessive friction and heat, which may cause premature failure of the belt.

v belt idler pulleys by size

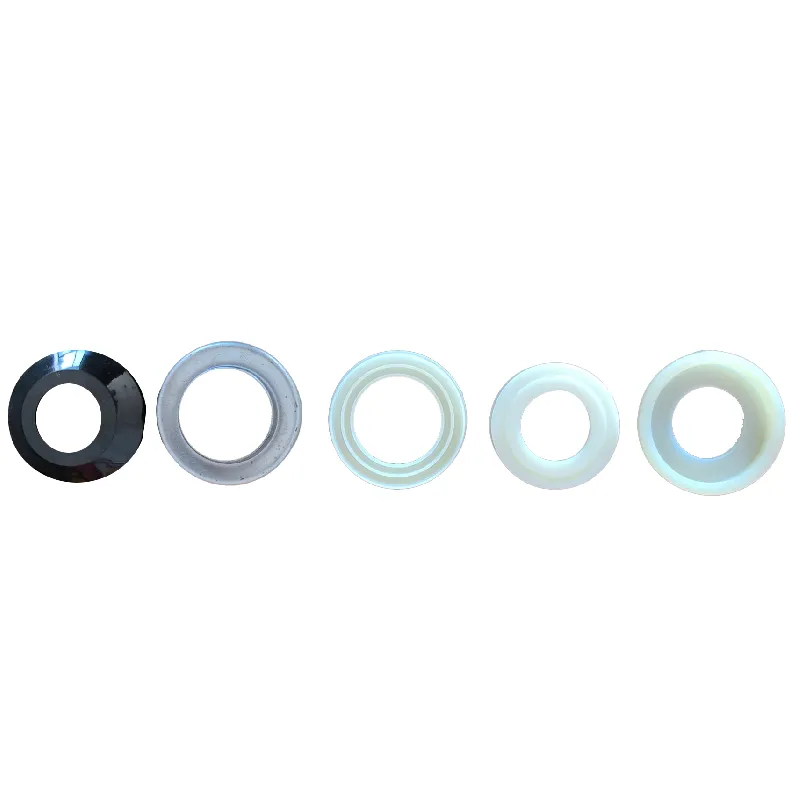

3. Groove Profile The groove profile on the idler pulley must match the V-belt's design. There are various profiles, including classical, narrow, or wedge styles, which correspond to different belt types. Ensuring compatibility prevents unnecessary wear and enhances performance.

Material Considerations

The material of the idler pulley is another important aspect that can affect its performance. Common materials used for idler pulleys include plastic, aluminum, and steel. Each material has its advantages and disadvantages; for instance, plastic pulleys are lightweight and resistant to corrosion but may not endure heavy loads as well as metal pulleys. On the other hand, steel pulleys are robust and suitable for high-load applications but may require regular maintenance to prevent rust and wear.

Maintenance and Replacement

To ensure the longevity of idler pulleys, regular maintenance is essential. This includes checking for any signs of wear, such as cracks or wear marks on the pulley and the belt. Any noticeable damage indicates that it’s time for a replacement. Ignoring these signs can lead to failure of the pulley or the belt, resulting in costly downtime and repairs.

Conclusion

In summary, V-belt idler pulleys are critical components that require careful consideration regarding size, material, and maintenance. Proper sizing ensures optimal tension and alignment, leading to improved efficiency and longevity of the mechanical system. Understanding the specific needs of your application will guide you in selecting the right idler pulleys, ultimately contributing to the reliability and performance of your machinery. Regular inspection and maintenance will further enhance these benefits, providing peace of mind as you ensure smooth operation in your equipment.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025