Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Function and Design of Conveyor Head Rollers in Material Handling Systems

The Importance of Conveyor Head Rollers in Material Handling Systems

Conveyor systems have become an integral part of modern industries, providing a seamless solution for transporting materials across various stages of production and logistics. Among the critical components of a conveyor system is the head roller, also known as the drive roller. This component plays a pivotal role in ensuring the effective operation of the conveyor belt, impacting overall efficiency and productivity.

Understanding Conveyor Head Rollers

A conveyor head roller is typically located at the discharge end of a conveyor. It is responsible for driving the belt, facilitating the movement of materials from one location to another. The head roller is equipped with a motor that generates the necessary power to move the belt, enabling goods to be transferred smoothly and efficiently.

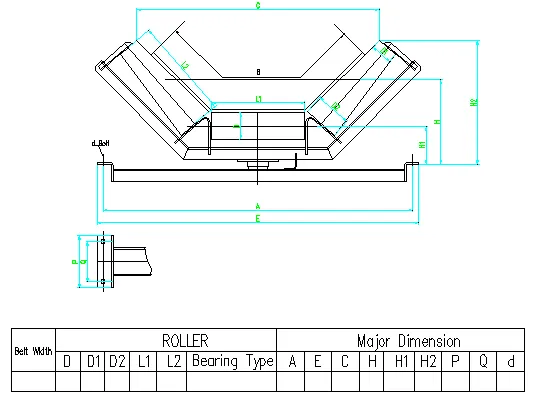

These rollers are designed to withstand significant wear and tear, given their constant exposure to heavy loads and various environmental conditions. They are typically made from high-quality materials, such as steel or rubber, to ensure durability and long-lasting performance. Additionally, they can vary in size and configuration, depending on the specific application and the type of material being transported.

Key Functions of Head Rollers

1. Belt Drive Mechanism The primary function of the head roller is to drive the conveyor belt. The motorized roller rotates and creates tension on the belt, which pulls it forward. The efficiency of this mechanism directly affects the speed and reliability of the material handling process.

2. Support for Material Transfer The head roller provides essential support for the belt, helping to maintain its stability and alignment during operation. Proper alignment is crucial in preventing belt misalignment, which can lead to material spillage and system downtime.

3. Load Distribution As materials are transferred onto the conveyor system, the head roller helps in evenly distributing the load across the belt. This distribution is vital for ensuring that the belt does not sag or become overwhelmed, thus reducing the risk of belt failure.

conveyor head roller

Maintenance Considerations

Maintaining the conveyor head roller is essential for ensuring the longevity and efficiency of the conveyor system. Regular inspection and maintenance can prevent common issues such as wear and tear, misalignment, and bearing failure. Here are some key maintenance practices

- Lubrication Regularly lubricating the roller bearings helps reduce friction and wear, prolonging the lifespan of the head roller. - Alignment Checks Ensuring that the head roller is correctly aligned with the rest of the conveyor system helps maintain smooth belt operation and prevents unnecessary wear. - Belt Tension Monitoring Proper tensioning of the conveyer belt is crucial. Regular checks should be conducted to ensure that the belt is neither too loose nor too tight, which can lead to operational inefficiencies.

Innovations and Advancements

Recent advancements in technology have also led to the development of improved head roller designs that enhance performance and efficiency. For instance, some modern head rollers incorporate features such as variable speed drives, allowing for more precise control over belt movement. Additionally, advances in materials science have led to the creation of more durable roller components that can withstand harsher operating conditions.

Furthermore, the integration of sensors and IoT technology allows for real-time monitoring of the head roller's performance. This capability enables proactive maintenance, reducing the risk of unexpected breakdowns and enhancing overall system reliability.

Conclusion

In conclusion, conveyor head rollers are crucial components in any material handling system. Their role as the driving force behind conveyor belts underscores their significance in various industries, from manufacturing to logistics. By understanding their functions, maintaining their efficiency, and leveraging technological advancements, businesses can optimize their operations, improve productivity, and reduce operational costs. As industries continue to evolve and grow, the importance of reliable conveyor head rollers will remain a cornerstone of effective material handling solutions.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025