Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Basics of Belt Drive Systems and Their Applications in Mechanical Engineering

Understanding Belt Drive Pulleys Mechanisms and Applications

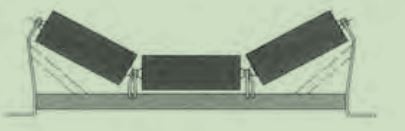

Belt drive pulleys are integral components in mechanical systems that utilize belts to transfer power between rotating shafts. Their design and functionality play a crucial role in various applications, from small domestic devices to large industrial machines. Understanding the principles behind belt drive pulleys helps in optimizing performance and maintenance in various settings.

How Belt Drive Pulleys Work

At its core, a belt drive system consists of two or more pulleys connected by a belt, which can be flat or V-shaped. The basic mechanism relies on friction as one pulley (the driver) rotates, it pulls the belt, which in turn rotates the other pulley (the driven). The interplay of the pulleys and the belt creates a mechanical advantage, allowing a smaller driver pulley to turn a larger driven pulley, or vice versa, effectively changing the speed and torque output of the system.

The arrangement of the pulleys defines the performance characteristics of the belt drive system. For instance, when using a small driver pulley and a larger driven pulley, you can achieve a higher torque at the cost of speed (a reduction gear effect). Conversely, a larger driver pulley and a smaller driven pulley will increase speed but reduce torque. This versatility is one reason why belt drive systems are widely utilized across various industries.

Types of Belt Drive Pulleys

Belt drive pulleys come in several designs

1. V-Pulleys These pulleys have a V-shaped groove, which helps the belt fit snugly and minimizes slippage. V-pulleys are particularly common in applications requiring power transmission at higher speeds or when maintaining tension is critical.

2. Flat Pulleys These have a flat surface and are used with flat belts. They are often found in simple systems where space is a consideration, though slippage can be an issue if inadequate tension is not maintained.

3. Idler Pulleys These pulleys do not transmit power directly but help guide the belt, maintaining proper tension and alignment. They can extend the life of the belt and improve efficiency.

Applications of Belt Drive Pulleys

Belt drive systems using pulleys are ubiquitous across various sectors

belt drive pulley

- Automotive In vehicles, belt drive systems power accessories such as alternators, water pumps, and air conditioning units. Understanding these systems is crucial for maintenance and repair work.

- Manufacturing Conveyor systems often rely on belt drives to move materials through different stages of production. The adaptability of belt drive pulleys allows for the design of efficient layouts that enhance workflow.

- Agriculture Many agricultural machines, including tractors and combines, employ belt drive systems to operate various implements, like harrows and seeders, where reliable power transfer is essential.

- Home Appliances Simple devices like washing machines and lawnmowers often use belt drives for their efficiency and ease of maintenance.

Maintenance and Best Practices

To ensure optimal performance of belt drive pulley systems, regular maintenance is necessary. Here are some best practices

- Tension Checks Regularly check the tension of the belt to prevent slippage and premature wear. Over-tightening can lead to bearing damage in pulleys.

- Alignment Proper alignment of pulleys is critical. Misalignment can lead to increased wear on the belt and pulleys, causing system inefficiency.

- Inspection Regularly inspecting belts for signs of wear, such as fraying or cracking, can prevent costly breakdowns and improve overall reliability.

Conclusion

Belt drive pulleys are essential components in the realm of power transmission. Their simple yet effective design allows for a wide range of applications, providing versatility that few other systems can match. Understanding the principles of belt drive systems, along with proper maintenance practices, can significantly enhance their performance and longevity in any mechanical setup. Whether in an industrial plant or a household appliance, belt drive pulleys continue to play a pivotal role in efficient power transmission.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025