Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu different types of conveyor rollers

Different Types of Conveyor Rollers

Conveyor systems are an essential component of material handling processes in various industries, from manufacturing to distribution. At the heart of these systems are conveyor rollers, which play a pivotal role in transporting materials efficiently. Understanding the different types of conveyor rollers is crucial for selecting the right equipment for specific applications. In this article, we will explore the various types of conveyor rollers, their features, and their applications.

1. Live Roller Conveyors

Live roller conveyors are designed with powered rollers that drive the conveyor belt. They are commonly used in environments where items need to be transported at variable speeds or where accumulation is necessary. The powered rollers can be driven by a motorized belt located underneath the rollers or by direct drive systems. This type of conveyor roller is ideal for moving products like cartons, pallets, and packages, providing an efficient means of transporting goods while allowing for accumulation, merging, and diverting of items.

2. Gravity Roller Conveyors

Gravity roller conveyors utilize the force of gravity to move items down a sloped surface. These conveyors are typically made with a series of parallel rollers that allow products to roll along the surface without the need for power. Gravity roller conveyors are particularly advantageous for applications where loads need to move downhill or where manual loading and unloading are feasible. They are commonly used in warehouses and shipping facilities for sorting and transporting packages.

3. Heavy-Duty Rollers

For transporting heavy loads, heavy-duty conveyor rollers are essential. These rollers are constructed from robust materials like steel and are designed to support a significant weight while maintaining structural integrity. Heavy-duty rollers are typically used in industries such as manufacturing, steel processing, and mining, where large and heavy materials need to be moved. They provide durability and strength, essential for environments with high loads and demanding conditions.

different types of conveyor rollers

Impact rollers are specifically designed to absorb shock and protect the conveyor system from damage during the loading process. They are commonly installed at points where materials are dropped onto the conveyor, such as at feed chutes. Impact rollers are equipped with features like rubber coverings or specialized end caps that cushion the impact of heavy materials, reducing wear and prolonging the life of the conveyor. These rollers are crucial in industries where harsh handling of materials is inevitable.

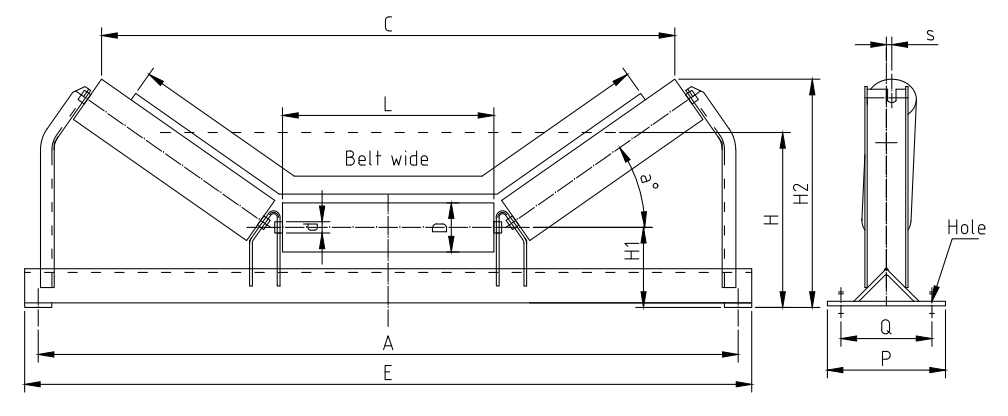

5. Idler Rollers

Idler rollers support the conveyor belt’s movement and help maintain its tension. These rollers are typically not powered but play an essential role in ensuring the smooth operation of the conveyor system. Idler rollers are used in various types of conveyor systems, including belt conveyors, to guide and support the belt as it travels. They are available in various sizes and configurations, depending on the specific requirements of the conveyor system.

6. Roller Bed Conveyors

Roller bed conveyors consist of a series of rollers placed close together, forming a flat surface for items to roll over. This design minimizes friction, making it easier to move heavy loads. Roller bed conveyors are ideal for transporting products over long distances, as they provide a smooth and efficient passage while minimizing wear on the conveyor components. They are commonly used in warehouses, distribution centers, and manufacturing facilities.

7. Specialty Rollers

In addition to standard roller types, there are also specialty rollers designed for specific applications. These include rollers with features such as stainless steel construction for food service environments or rollers with anti-static properties for handling electronic components. Specialty rollers can be customized to meet unique industry demands, ensuring optimal performance in diverse environments.

Conclusion

Understanding the different types of conveyor rollers is essential for optimizing material handling processes. Each type of roller has its unique features and applications, making it important to select the right roller for specific operational needs. By considering factors such as load capacity, material type, and the specific requirements of the conveyor system, businesses can enhance their efficiency and productivity. With the right conveyor roller in place, organizations can ensure smooth and reliable operations, ultimately leading to improved logistics and supply chain management.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025