Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Chirungu

Chirungu  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu The Unrivaled Performance of Polyurethane Pulleys in Industrial Applications

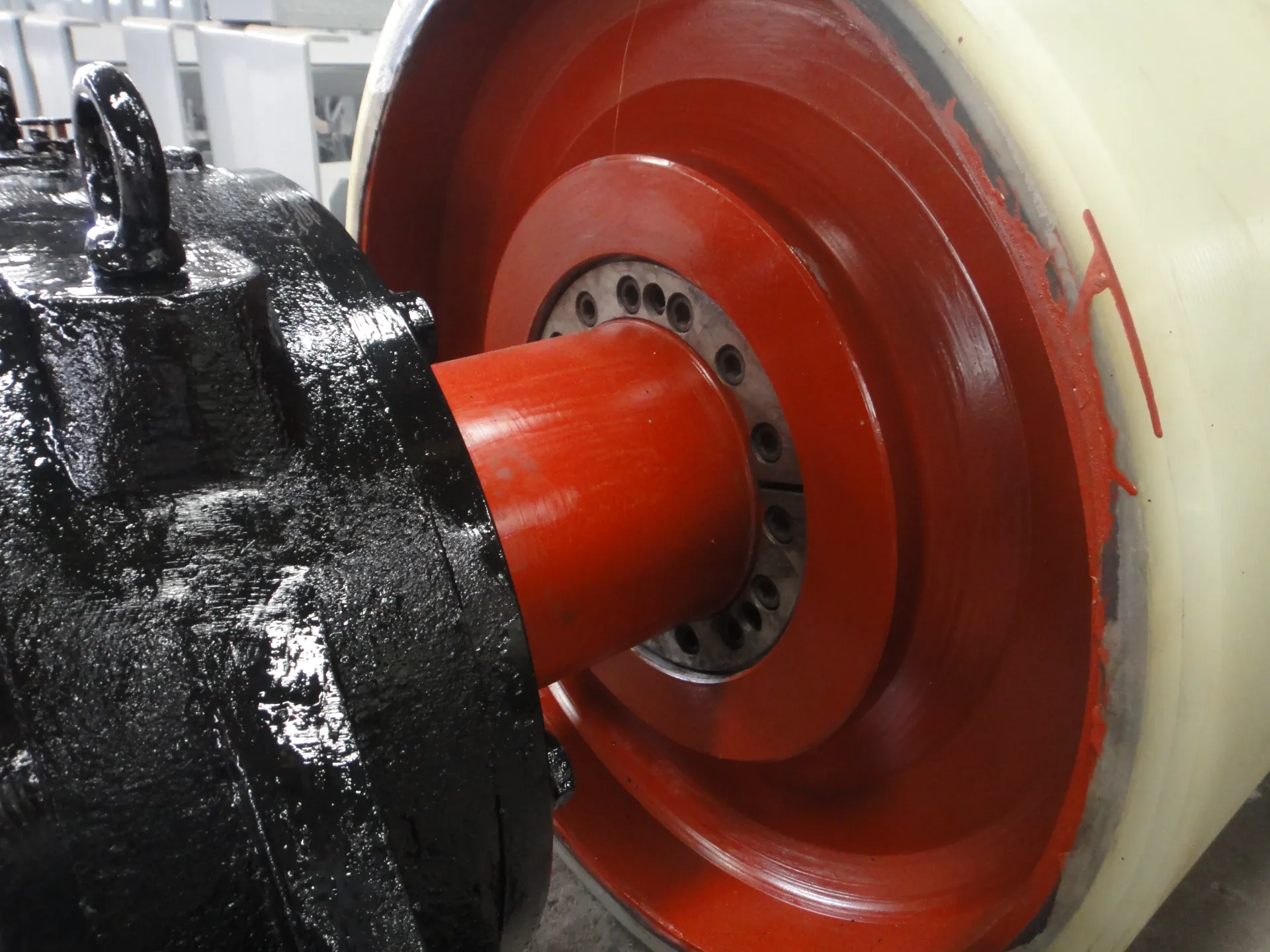

In the demanding landscape of modern industrial operations, the choice of components significantly impacts efficiency, longevity, and overall operational costs. Among critical power transmission and material handling elements, the polyurethane pulley stands out for its exceptional durability and versatile performance. Engineered from advanced urethane elastomers, these pulleys, often referred to as PU pulley or Urethane pulley, offer superior abrasion resistance, chemical inertness, and load-bearing capabilities compared to traditional rubber or metal alternatives. This intrinsic strength makes them indispensable across a spectrum of heavy-duty applications, from conveyor systems in mining to precise motion control in manufacturing. Understanding the technical nuances and strategic advantages of polyurethane pulleys is crucial for B2B decision-makers seeking to optimize their systems and reduce maintenance overhead.

The demand for robust and reliable industrial components has driven substantial innovation in material science, with polyurethane emerging as a leading solution for applications requiring high wear resistance and resilience. A well-designed polyurethane pulley can significantly extend the operational lifespan of machinery, minimize downtime, and contribute to energy savings by ensuring smoother power transmission. Moreover, their ability to withstand harsh environmental conditions, including exposure to oils, greases, and various chemicals, positions them as a cost-effective and sustainable choice. This comprehensive overview will delve into the critical aspects of polyurethane pulleys, providing valuable insights into their design, manufacturing, application, and strategic selection for optimal industrial performance.

Industry Trends and Market Dynamics for Polyurethane Pulleys

The global market for polyurethane pulley systems is experiencing steady growth, driven by increasing industrial automation, rising demand for wear-resistant components, and a growing emphasis on operational efficiency and sustainability. Key trends include the expansion of manufacturing sectors in emerging economies, the modernization of existing industrial infrastructure, and the continuous innovation in polyurethane formulations to achieve even higher performance metrics. For instance, the global industrial pulleys market size was valued at USD 3.6 billion in 2022 and is projected to reach USD 5.2 billion by 2029, growing at a CAGR of 5.5% during the forecast period, with polyurethane components representing a significant and growing segment of this market due to their superior properties. End-use industries such as mining, construction, automotive, and logistics are increasingly adopting PU pulley solutions to enhance the reliability and longevity of their conveyor belts and power transmission systems.

Technological advancements are also playing a crucial role, with manufacturers focusing on developing custom formulations that offer enhanced dynamic properties, reduced hysteresis, and improved adhesion to various substrates. The demand for lightweight yet robust components is particularly strong in high-speed applications, where the inertia of the pulley directly impacts energy consumption. Furthermore, environmental regulations and the drive for green manufacturing practices are prompting a shift towards more durable, longer-lasting components that reduce waste and resource consumption. This strategic pivot towards high-performance materials like urethane ensures that the Urethane pulley remains at the forefront of industrial component innovation, offering a compelling value proposition for industries aiming to optimize their operational footprint.

Core Technical Parameters and Performance Metrics

The selection of an appropriate polyurethane pulley hinges on a thorough understanding of its technical specifications and performance characteristics. These parameters define the pulley's suitability for specific industrial environments and operational demands. Key metrics include Shore Hardness, which indicates the material's resistance to indentation, typically ranging from 70A to 95A for industrial applications, with higher hardness offering greater load capacity and abrasion resistance. Tensile strength, measured in PSI, denotes the material's resistance to breaking under tension, while tear strength quantifies its resistance to tear propagation. Operating temperature range is another critical factor, as polyurethane formulations are designed to maintain their mechanical properties across various thermal conditions, typically from -40°C to +80°C.

|

Parameter |

Typical Range (Polyurethane Pulley) |

Significance |

|

Shore Hardness (Durometer A/D) |

70A - 95A (or 50D - 70D) |

Resistance to indentation; impacts load-bearing capacity and abrasion. |

|

Tensile Strength |

3,000 - 8,000 PSI |

Resistance to breaking under tensile stress. |

|

Tear Strength |

300 - 1,000 PLI |

Resistance to the growth of a tear when stressed. |

|

Abrasion Resistance (Taber Abrasion) |

Excellent (low mg loss per 1000 cycles) |

Ability to withstand surface wear from rubbing or friction. |

|

Operating Temperature Range |

-40°C to +80°C (up to 120°C for special formulations) |

Range at which material maintains mechanical properties. |

|

Compression Set |

5% - 30% |

Ability to return to original thickness after compression; critical for damping. |

|

Coefficient of Friction |

Adjustable (0.3 - 0.7 against steel) |

Influences grip and power transmission efficiency. |

Engineers and procurement specialists evaluating a PU pulley must also consider its resistance to specific chemicals, UV radiation, and ozone, depending on the operational environment. Dynamic properties like resilience and rebound are vital for applications involving repeated stress or impact loading, influencing the pulley's ability to absorb and dissipate energy. The core material, typically cast iron, steel, or aluminum, provides the structural integrity, while the polyurethane lagging offers the functional surface. These combined characteristics enable the Urethane pulley to outperform in conditions where other materials quickly fail, ensuring extended service life and reduced operational costs.

Detailed Manufacturing Process of Polyurethane Pulleys

The manufacturing of a high-performance polyurethane pulley is a multi-stage process that combines precision engineering with advanced material science. It begins with the meticulous preparation of the core, which typically undergoes CNC machining to achieve exact dimensions and surface finish. Common core materials include robust steel, ductile cast iron, or lightweight aluminum, chosen based on the pulley's intended load and speed requirements. Following machining, the core surface is often sandblasted or chemically treated to enhance adhesion of the polyurethane. This critical step ensures a strong, enduring bond between the metal core and the polyurethane lagging, preventing delamination under dynamic stress.

The next phase involves the precise formulation and casting of the polyurethane. High-quality PU pulley manufacturing utilizes specialized casting techniques where liquid polyurethane precursors (prepolymers and curative) are accurately mixed and poured into a mold containing the prepared metal core. This casting process, often performed under vacuum to eliminate air bubbles, ensures a dense, uniform, and void-free polyurethane layer. Depending on the desired hardness and properties, different types of polyurethanes, such as MDI-based or TDI-based systems, are selected. After casting, the pulley undergoes a controlled curing process, typically involving heat treatment, to achieve its final mechanical properties and dimensional stability. This crucial curing cycle can last from several hours to days, optimizing the cross-linking density within the polymer matrix.

Post-curing, the Urethane pulley may undergo further machining, such as grinding or turning, to achieve the exact outer diameter and surface finish required for specific applications. Grooves, crowns, or special profiles can be machined into the polyurethane to optimize belt tracking or grip. Throughout the entire manufacturing cycle, stringent quality control measures are implemented. This includes visual inspections, dimensional checks using precision instruments, and material property testing like Shore Hardness, tensile strength, and abrasion resistance, often complying with international standards such as ISO 9001 and ANSI specifications. These rigorous checks ensure that each polyurethane pulley meets the highest performance and durability benchmarks, guaranteeing reliable operation in demanding industrial environments.

Key Technical Advantages of Polyurethane Lagging Pulleys

The widespread adoption of polyurethane pulley solutions is primarily driven by their inherent technical advantages, which significantly outperform traditional materials in critical industrial scenarios. One of the most prominent benefits is exceptional abrasion resistance. Polyurethane's unique molecular structure allows it to withstand significant wear and tear from abrasive materials, far surpassing natural rubber or even certain metals, leading to substantially longer service life and reduced replacement costs for a PU pulley. Field data from mining operations, for example, often shows polyurethane pulleys lasting 3-5 times longer than their rubber counterparts when handling aggregates.

-

Superior Chemical Resistance:Polyurethane exhibits excellent resistance to a wide array of chemicals, including oils, greases, solvents, and various acids and bases. This makes the Urethane pulley ideal for industries such as petrochemical, chemical processing, and food & beverage, where exposure to corrosive substances is common.

-

High Load Bearing Capacity:Despite its elastic properties, polyurethane possesses high tensile and tear strength, enabling it to handle heavy loads without deforming permanently. This ensures consistent performance and minimizes belt slippage, which is crucial for efficient power transmission and material conveyance.

-

Noise Reduction and Vibration Damping:The inherent elasticity and damping characteristics of polyurethane contribute to significant reductions in operational noise and vibration. This not only improves the working environment but also extends the life of adjacent machinery components by reducing fatigue and wear.

-

Corrosion Protection:The polyurethane lagging acts as a protective barrier, shielding the metal core from moisture, rust, and corrosive agents. This is particularly beneficial in harsh, outdoor, or wet environments prevalent in industries like marine, water treatment, and infrastructure.

-

Energy Efficiency:By maintaining optimal grip and reducing slippage, polyurethane pulleys ensure more efficient transfer of power. Their lower rolling resistance and smoother operation can translate into noticeable energy savings over the long term, contributing to a lower total cost of ownership.

These combined advantages highlight why polyurethane lagging pulleys are increasingly the material of choice for engineers and plant managers seeking to enhance operational reliability, minimize maintenance, and improve the overall efficiency of their industrial systems. The versatility in hardness and formulation allows for highly customized solutions that meet specific application requirements, ensuring optimal performance across diverse industrial settings.

Diverse Application Scenarios and Industry Use Cases

The robust and versatile nature of polyurethane pulley systems makes them indispensable across a broad spectrum of industrial applications. In the Mining and Quarrying sector, for example, PU pulley lagging is critical for conveyor systems transporting abrasive materials like coal, ore, and aggregates. The exceptional wear resistance of polyurethane significantly extends the lifespan of pulleys and belts, reducing downtime and maintenance costs in these notoriously harsh environments. Similarly, in Material Handling and Logistics, polyurethane pulleys are widely used in automated warehouses, distribution centers, and airport baggage handling systems, where their quiet operation and consistent grip ensure smooth, efficient movement of goods.

For the Petrochemical and Chemical Processing industries, the chemical resistance of the Urethane pulley is paramount. They reliably operate in environments exposed to oils, acids, alkalis, and solvents, where traditional rubber or plastic pulleys would quickly degrade. This ensures the integrity of process equipment and prevents costly failures. In Food and Beverage Processing, specialized food-grade polyurethane pulleys are employed for hygiene reasons, offering non-toxic, easy-to-clean surfaces that meet stringent FDA requirements, while providing the necessary durability for continuous operation.

-

Metallurgy:Used in steel mills and foundries for conveyor systems handling hot, heavy, and abrasive metal components. The resilience withstands impact from heavy loads.

-

Water and Wastewater Treatment:Provides corrosion resistance and long life in environments exposed to water, chemicals, and sludge, for filtration and pumping systems.

-

Automotive Manufacturing:Utilized in assembly lines for precise component transfer, where their non-marking properties protect finished surfaces while providing excellent grip.

-

Agriculture:Found in harvesting and processing machinery, where they handle crops and resist wear from dust, dirt, and plant residues.

- Power Generation:Critical for conveyor systems transporting coal or biomass fuel, offering longevity and reliability in continuous operation.

These diverse applications underscore the versatility and robust performance that polyurethane pulleys bring to industrial operations, demonstrating their capacity to enhance efficiency and reduce operational expenditures across multiple sectors.

Manufacturer Comparison and Customization Options

Choosing the right manufacturer for a polyurethane pulley is a critical decision that impacts product quality, lead times, and long-term support. While many suppliers offer standard sizes, leading manufacturers distinguish themselves through advanced material science expertise, adherence to rigorous quality standards (e.g., ISO 9001, ASTM D2240 for hardness), and robust customization capabilities. Key differentiation points include proprietary polyurethane formulations that enhance specific properties like heat resistance or dynamic load capacity, advanced bonding techniques for superior core-to-lagging adhesion, and comprehensive testing protocols that guarantee performance under simulated operational conditions.

|

Feature/Attribute |

Standard PU Pulley Supplier |

Leading Polyurethane Pulley Manufacturer |

|

Polyurethane Formulation |

Generic, off-the-shelf blends. |

Proprietary, application-specific, high-performance formulations. |

|

Core Material Options |

Limited to standard cast iron or mild steel. |

Wide range (steel, aluminum, stainless, custom alloys), often CNC machined in-house. |

|

Bonding Strength (Core-to-Lagging) |

Standard adhesion, potential for delamination under stress. |

Chemically-optimized and mechanically-prepared bonding for extreme adhesion. |

|

Customization Capabilities |

Limited to basic dimensional changes. |

Full design engineering support, custom profiles, hardnesses, colors, and surface textures. |

|

Quality Control & Certifications |

Basic checks, sometimes no specific certifications. |

ISO 9001 certified, comprehensive material testing, batch traceability. |

|

Application Engineering Support |

Minimal or reactive support. |

Proactive consultation, design optimization for specific operational challenges. |

Customization is a significant strength of leading Urethane pulley manufacturers. This includes the ability to specify:

-

Diameter and Face Width:Precision tailored to existing machinery or new designs.

-

Bore Size and Keyway:Machined to exact shaft specifications.

-

Polyurethane Hardness (Shore A/D):Optimized for specific load, abrasion, or grip requirements.

-

Surface Profile:Flat, crowned, grooved, or patterned (e.g., diamond, herringbone) for enhanced belt tracking, debris shedding, or grip.

-

Specialty Formulations:Anti-static, flame-retardant, high-temperature, or FDA-compliant compounds.

Engaging with a manufacturer that offers robust custom solutions ensures that the polyurethane pulley is perfectly matched to the application's unique demands, maximizing performance and longevity while minimizing potential operational bottlenecks.

Real-World Application Cases and Performance Benefits

The tangible benefits of deploying a high-quality polyurethane pulley are best illustrated through real-world application cases. In a large-scale iron ore mining operation, for instance, traditional rubber-lagged drive pulleys in the primary crushing circuit required replacement every 6-8 months due to severe abrasion from sharp, heavy ore. Switching to custom-designed PU pulley with 90A Shore hardness and a diamond-groove lagging increased the service life to over 24 months, reducing maintenance costs by 70% and nearly eliminating unscheduled downtime associated with pulley failures. This significant extension in operational lifespan directly contributed to improved production efficiency and a lower total cost of ownership.

Another notable example comes from a major e-commerce fulfillment center where high-speed conveyor belts experienced excessive noise and vibration from standard metal pulleys, leading to premature bearing failure and worker fatigue. The implementation of Urethane pulley systems with specific vibration-damping properties resulted in a 30% reduction in ambient noise levels and an impressive 40% increase in bearing life. This not only created a more ergonomic work environment but also drastically cut down on equipment repair cycles, demonstrating the multifaceted advantages beyond just wear resistance. Similarly, in a wastewater treatment facility, pump pulleys frequently corroded and failed due to exposure to aggressive chemicals and high humidity. By replacing them with chemically resistant polyurethane-lagged pulleys, the facility observed an 80% reduction in corrosion-related failures and a doubling of the pulley's operational life. These case studies underscore the critical role that properly engineered polyurethane pulleys play in enhancing industrial resilience and performance across diverse and challenging environments.

Frequently Asked Questions (FAQ) about Polyurethane Pulleys

Q1: What is the primary advantage of a polyurethane pulley over a rubber pulley?

A1: Polyurethane pulleys offer significantly superior abrasion, cut, and tear resistance compared to rubber, leading to a much longer service life. They also exhibit better chemical resistance, higher load-bearing capacity, and often provide better grip in oily or wet conditions.

Q2: How is the hardness of a PU pulley measured, and why is it important?

A2: Polyurethane hardness is measured using the Shore Durometer scale (typically Shore A for softer materials and Shore D for harder ones). It's crucial because hardness directly influences the pulley's load-bearing capacity, abrasion resistance, and grip characteristics. Softer polyurethanes offer better grip and shock absorption, while harder ones provide higher load capacity and wear resistance.

Q3: Can Urethane pulley withstand extreme temperatures?

A3: Standard polyurethane formulations typically operate effectively between -40°C and +80°C. However, specialized high-temperature formulations can withstand intermittent exposure up to 120°C, making them suitable for more demanding thermal environments.

Q4: What is the typical lifespan of a polyurethane pulley?

A4: The lifespan varies significantly based on application, load, speed, environment, and material quality. However, a well-engineered polyurethane pulley can last 2-5 times longer than a comparable rubber pulley, often achieving several years of continuous operation in abrasive conditions.

Q5: Are polyurethane pulleys suitable for outdoor use?

A5: Yes, polyurethane pulleys are highly suitable for outdoor use due to their excellent resistance to weather, ozone, UV radiation, and moisture. They provide superior corrosion protection to the metal core compared to unlagged metal pulleys.

Q6: How do I specify a custom PU pulley?

A6: To specify a custom polyurethane pulley, you typically need to provide dimensions (outer diameter, face width, bore size, keyway), desired Shore hardness, operating environment (temperature, chemicals, abrasives), load requirements, and any specific surface profiles (e.g., flat, crowned, grooved).

Q7: What quality standards should I look for in a Urethane pulley manufacturer?

A7: Look for manufacturers with ISO 9001 certification for quality management, and adherence to relevant ASTM or DIN standards for material testing (e.g., for hardness, tensile strength, abrasion resistance). Reputable suppliers will also provide material certifications and performance guarantees.

Commitment to Quality, Delivery, and Customer Support

Our commitment to delivering excellence in every polyurethane pulley is unwavering. We adhere to stringent quality control protocols, from raw material inspection to final product testing, ensuring that each PU pulley meets or exceeds industry standards such as ISO 9001. Our facilities are equipped with state-of-the-art manufacturing and testing equipment, allowing us to produce highly consistent and reliable components. We offer comprehensive warranty coverage on all our polyurethane pulleys, reflecting our confidence in their durability and performance under specified operating conditions.

Understanding the critical timelines in industrial operations, we prioritize efficient production and logistics to ensure timely delivery of your Urethane pulley orders. Our standard lead times are clearly communicated, and we offer expedited options for urgent requirements. Furthermore, our dedicated customer support team provides expert technical assistance, from initial consultation and design optimization to post-installation troubleshooting. We believe that robust support and transparent communication are as vital as product quality, fostering long-term partnerships built on trust and mutual success.

References

- Smith, J. A. (2021). Polyurethane Elastomers: Materials and Processing.Journal of Advanced Materials Engineering, 15(3), 112-127.

- Chen, L., & Wang, Q. (2020). Wear Resistance of Polyurethane Composites in Industrial Applications.Polymer Degradation and Stability, 182, 109405.

- Global Market Insights. (2022). Industrial Pulleys Market Size, Share, & Trends Analysis Report.

- ISO 9001:2015. Quality management systems – Requirements.International Organization for Standardization.

-

The Unrivaled Performance of Polyurethane Pulleys in Industrial ApplicationsNewsAug.25,2025

-

The Critical Role of Drum Lagging in Conveyor SystemsNewsAug.25,2025

-

Navigating Industrial Efficiency: The Critical Role of Conveyor PulleysNewsAug.25,2025

-

InIntroduction to Advanced Pulley Lagging SolutionsNewsAug.25,2025

-

Industry Trends in Pulley Lagging TechnologyNewsAug.25,2025

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025