Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor belt parts and functions

Understanding Conveyor Belt Parts and Their Functions

Conveyor belts are essential components of various industries, facilitating the smooth and efficient movement of goods and materials

. Understanding the parts of a conveyor belt and their functions can provide insight into how these systems operate and their importance in manufacturing, warehousing, and logistics.1. Belt The belt itself is the most recognizable component of a conveyor system. Typically made from rubber, fabric, or metal, the conveyor belt transports materials from one point to another. The choice of material depends on the product being moved and the environment it operates in. For example, heavy-duty belts are used for transporting bulk materials, while lighter belts suit smaller packages.

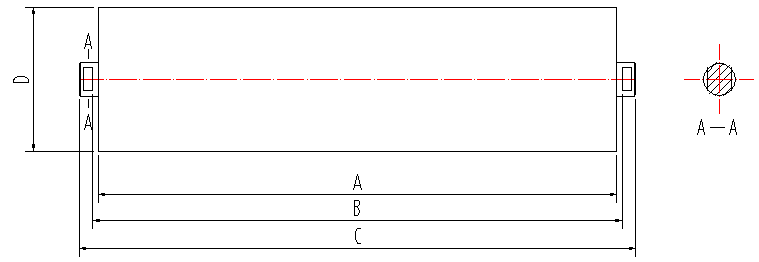

2. Rollers Rollers are cylindrical components that support and guide the belt. They are strategically placed along the conveyor line. The primary functions of rollers include reducing friction, providing a surface for the belt to run on, and supporting the weight of the materials being transported. There are different types of rollers, such as idler rollers, which keep the belt aligned, and drive rollers, which are powered by motors to move the belt.

3. Frame The frame is the structural backbone of the conveyor system. It provides stability and support for all other components. Frames can vary in design, including fixed frameworks or adjustable ones to accommodate different conveyor lengths. Materials used for the frame may include steel or aluminum, chosen based on the required strength and weight capacity.

conveyor belt parts and functions

4. Drive system The drive system powers the conveyor belt. It typically consists of a motor, gear box, and pulley. The motor provides the necessary force to move the belt, while the gear box helps control the speed. The pulleys, often located at both ends of the conveyor, are crucial for maintaining tension on the belt and facilitating movement.

5. Tensioning device A tensioning device is responsible for maintaining the proper tension on the conveyor belt. Adequate tension is crucial to prevent slippage and ensure smooth operation. The tension can be adjusted using devices such as take-up units, which allow for the belt's length to be altered as it stretches over time.

6. Safety features Safety features, including emergency stop buttons and guards, are integral to conveyor systems. These components ensure safe operation, protecting both the equipment and personnel working nearby.

In conclusion, understanding the various parts of a conveyor belt and their functions is vital for anyone involved in industries that rely on these systems. From the belt and rollers to the drive system and safety features, each component plays a crucial role in ensuring efficient and safe operations, making conveyor belts an indispensable part of modern manufacturing and logistics.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025