Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 17, 2025 17:03

Back to list

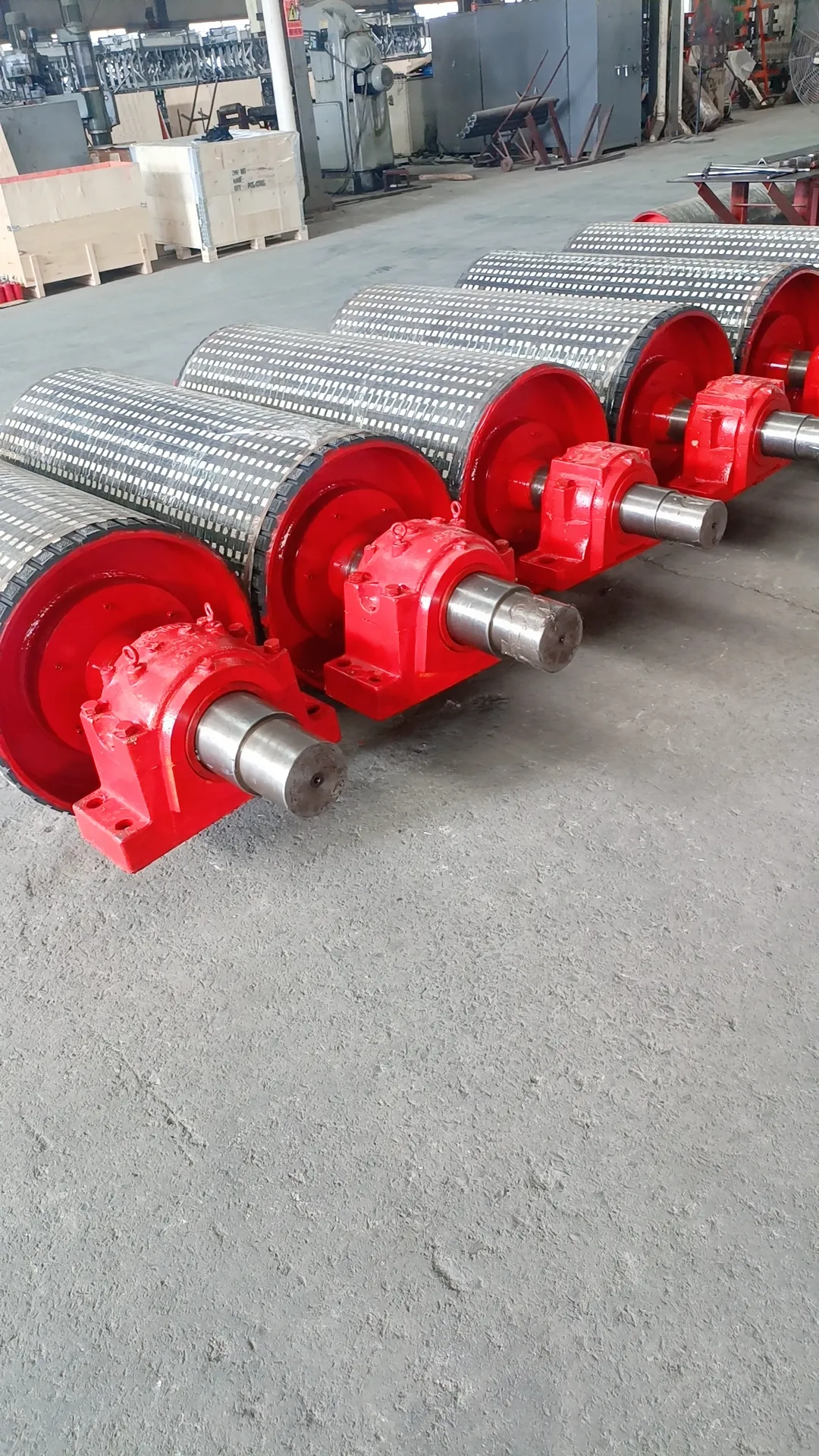

conveyor rollers and idlers

Conveyor rollers and idlers play an indispensable role in the material handling industry, ensuring that products move seamlessly along conveyor systems in various sectors such as mining, manufacturing, and logistics. For businesses looking to optimize efficiency and reliability, understanding the nuances of these components is crucial.

Authority in the domain of conveyor systems is established through decades of research and engineering advancements. Industry leaders continuously innovate to enhance the effectiveness of rollers and idlers. For example, the introduction of self-cleaning idlers has significantly diminished the buildup of material on the roller surface, a problem that previously led to increased maintenance and shortened belt life. This authoritative knowledge is continuously shared across the industry through seminars, technical papers, and collaborations with institutions dedicated to advancing industrial engineering standards. Trustworthiness is built on the consistent performance delivered by well-designed conveyor components. Suppliers with a reputation for producing reliable rollers and idlers often provide comprehensive warranties and customer service, ensuring their clients not only receive high-quality products but also ongoing support. Choosing trusted brands with proven track records can alleviate concerns regarding product performance and longevity. In conclusion, the integration of conveyor rollers and idlers into material handling systems is both an art and a science. It requires a blend of real-world experience, specialized knowledge, authoritative insight, and a commitment to trustworthiness. By focusing on these elements, businesses can ensure the operational efficiency, safety, and sustainability of their conveyor systems, ultimately leading to measurable economic benefits.

Authority in the domain of conveyor systems is established through decades of research and engineering advancements. Industry leaders continuously innovate to enhance the effectiveness of rollers and idlers. For example, the introduction of self-cleaning idlers has significantly diminished the buildup of material on the roller surface, a problem that previously led to increased maintenance and shortened belt life. This authoritative knowledge is continuously shared across the industry through seminars, technical papers, and collaborations with institutions dedicated to advancing industrial engineering standards. Trustworthiness is built on the consistent performance delivered by well-designed conveyor components. Suppliers with a reputation for producing reliable rollers and idlers often provide comprehensive warranties and customer service, ensuring their clients not only receive high-quality products but also ongoing support. Choosing trusted brands with proven track records can alleviate concerns regarding product performance and longevity. In conclusion, the integration of conveyor rollers and idlers into material handling systems is both an art and a science. It requires a blend of real-world experience, specialized knowledge, authoritative insight, and a commitment to trustworthiness. By focusing on these elements, businesses can ensure the operational efficiency, safety, and sustainability of their conveyor systems, ultimately leading to measurable economic benefits.

Latest news

-

The Unrivaled Performance of Polyurethane Pulleys in Industrial ApplicationsNewsAug.25,2025

-

The Critical Role of Drum Lagging in Conveyor SystemsNewsAug.25,2025

-

Navigating Industrial Efficiency: The Critical Role of Conveyor PulleysNewsAug.25,2025

-

InIntroduction to Advanced Pulley Lagging SolutionsNewsAug.25,2025

-

Industry Trends in Pulley Lagging TechnologyNewsAug.25,2025

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

OUR PRODUCTS