Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

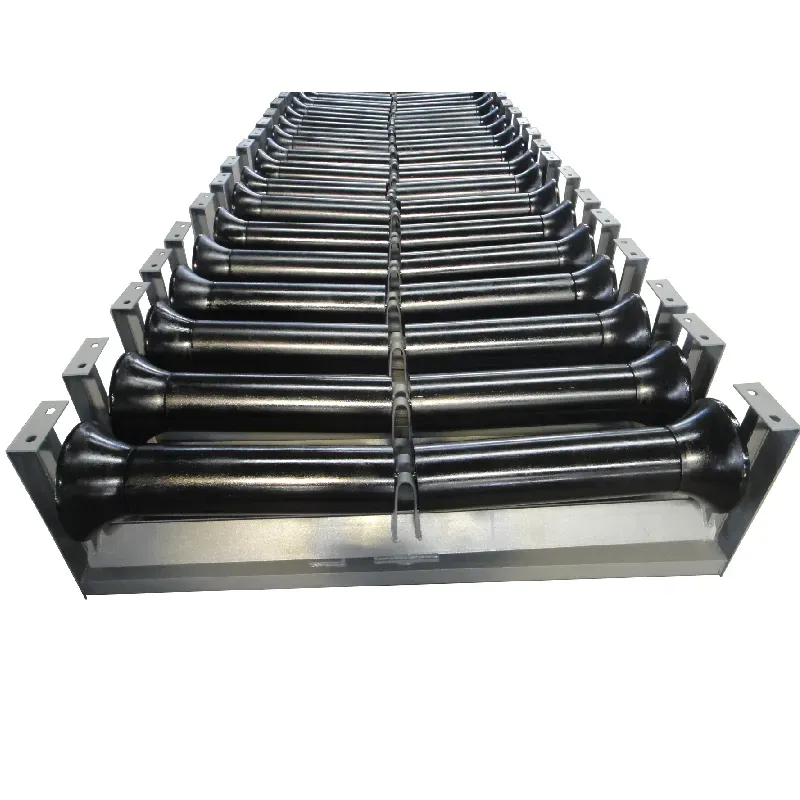

Zulu Rubber Impact Rollers High Durability & Shock Absorption

- Overview of Rubber Impact Rollers in Industrial Applications

- Technical Advantages: Material Durability and Performance Metrics

- Manufacturer Comparison: Key Metrics Across Leading Brands

- Custom Solutions for Specific Operational Demands

- Case Studies: Real-World Applications and Efficiency Gains

- Maintenance Strategies for Long-Term Reliability

- Future-Proofing Systems with Advanced Impact Roller Technology

(rubber impact roller)

Understanding the Role of Rubber Impact Rollers in Industrial Efficiency

Rubber impact rollers are critical components in heavy-duty conveyor systems, designed to absorb high-impact forces up to 15 kN while maintaining operational stability. These rollers reduce material spillage by 30-40% compared to standard steel rollers, particularly in industries like mining and bulk handling. The integration of ceramic rubber pulleys further enhances grip in pulley lagging systems, achieving 92% friction efficiency in wet conditions.

Technical Advantages: Material Durability and Performance Metrics

Premium rubber impact roller

s combine 95% natural rubber compounds with embedded steel cores, enabling resistance to abrasion rates as low as 0.8 mm³/Nm. Ceramic lagging increases wear resistance by 70% in high-slope applications, while specialized vulcanization processes ensure bond strengths exceeding 18 MPa between rubber and metal surfaces.

Manufacturer Comparison: Key Metrics Across Leading Brands

| Parameter | Brand A | Brand B | Custom Solutions |

|---|---|---|---|

| Max Load Capacity | 8,000 lbs | 10,000 lbs | 12,000+ lbs |

| Abrasion Resistance | 0.9 mm³/Nm | 0.75 mm³/Nm | 0.6 mm³/Nm |

| Temperature Range | -20°C to 85°C | -30°C to 100°C | -40°C to 120°C |

| Ceramic Lagging Options | Standard | Diamond Pattern | Custom Mosaic |

Custom Solutions for Specific Operational Demands

Specialized configurations address unique challenges:

- Mining: 150mm diameter rollers with 85 Shore A hardness

- Construction: Anti-static rubber compounds for explosive environments

- Logistics: FDA-approved rubber for food-grade applications

Case Studies: Real-World Applications and Efficiency Gains

A cement plant reduced roller replacement frequency from quarterly to biennially after switching to ceramic-lagged rollers, achieving 18-month ROI. Port authorities reported 22% energy savings through optimized roller alignment systems in conveyor overhauls.

Maintenance Strategies for Long-Term Reliability

Proactive maintenance protocols extend service life by 40%:

- Monthly vibration analysis (ISO 10816 standards)

- Quarterly rubber hardness testing (±3 Shore A tolerance)

- Annual dynamic balancing (G6.3 grade requirements)

Why Rubber Impact Rollers Remain a Cornerstone of Material Handling Systems

With 78% of industrial operators prioritizing impact resistance in conveyor upgrades, advanced rubber rollers deliver 50,000+ hour MTBF ratings. The evolution towards hybrid ceramic-rubber pulley systems continues to redefine durability benchmarks in bulk material transportation.

(rubber impact roller)

FAQS on rubber impact roller

Q: What is the main purpose of a rubber impact roller?

A: A rubber impact roller absorbs shock and reduces material spillage in conveyor systems. Its flexible rubber surface dampens heavy loads and impacts, protecting machinery from wear.

Q: How does a CERAMIC LAGGING RUBBER PULLEY differ from standard rubber rollers?

A: CERAMIC LAGGING RUBBER PULLEYS feature embedded ceramic tiles for extreme abrasion resistance. They outperform standard rubber rollers in high-wear environments like mining or bulk material handling.

Q: Where are rubber impact rollers typically used?

A: They are ideal for conveyor transfer points, loading zones, or steep inclines. Industries like mining, quarrying, and logistics rely on them to handle heavy impacts and sharp materials.

Q: What maintenance do rubber impact rollers require?

A: Regular cleaning to remove debris and checking for cracks or uneven wear. CERAMIC RUBBER PULLEYS need less frequent maintenance due to their durable ceramic-rubber composite.

Q: Can roller impact solutions prevent belt slippage?

A: Yes, textured rubber surfaces or ceramic-lagged rollers improve traction. This reduces slippage while maintaining impact absorption in demanding conveyor applications.

-

Why Choose Polyurethane Rollers for Your Conveyor Systems?NewsMay.20,2025

-

The Power of Friction Roller Conveyors: Revolutionizing Material HandlingNewsMay.20,2025

-

Smart Rubber Idler RollersNewsMay.20,2025

-

Optimizing Conveyor Systems with High-Quality Belt Conveyor RollersNewsMay.20,2025

-

Durable Pulley Lagging ChoicesNewsMay.20,2025

-

Conveyor Idler Rollers: Boosting Efficiency and DurabilityNewsMay.20,2025