Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Engleză

Engleză  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Outstanding Features Of Polyurethane Pulleys

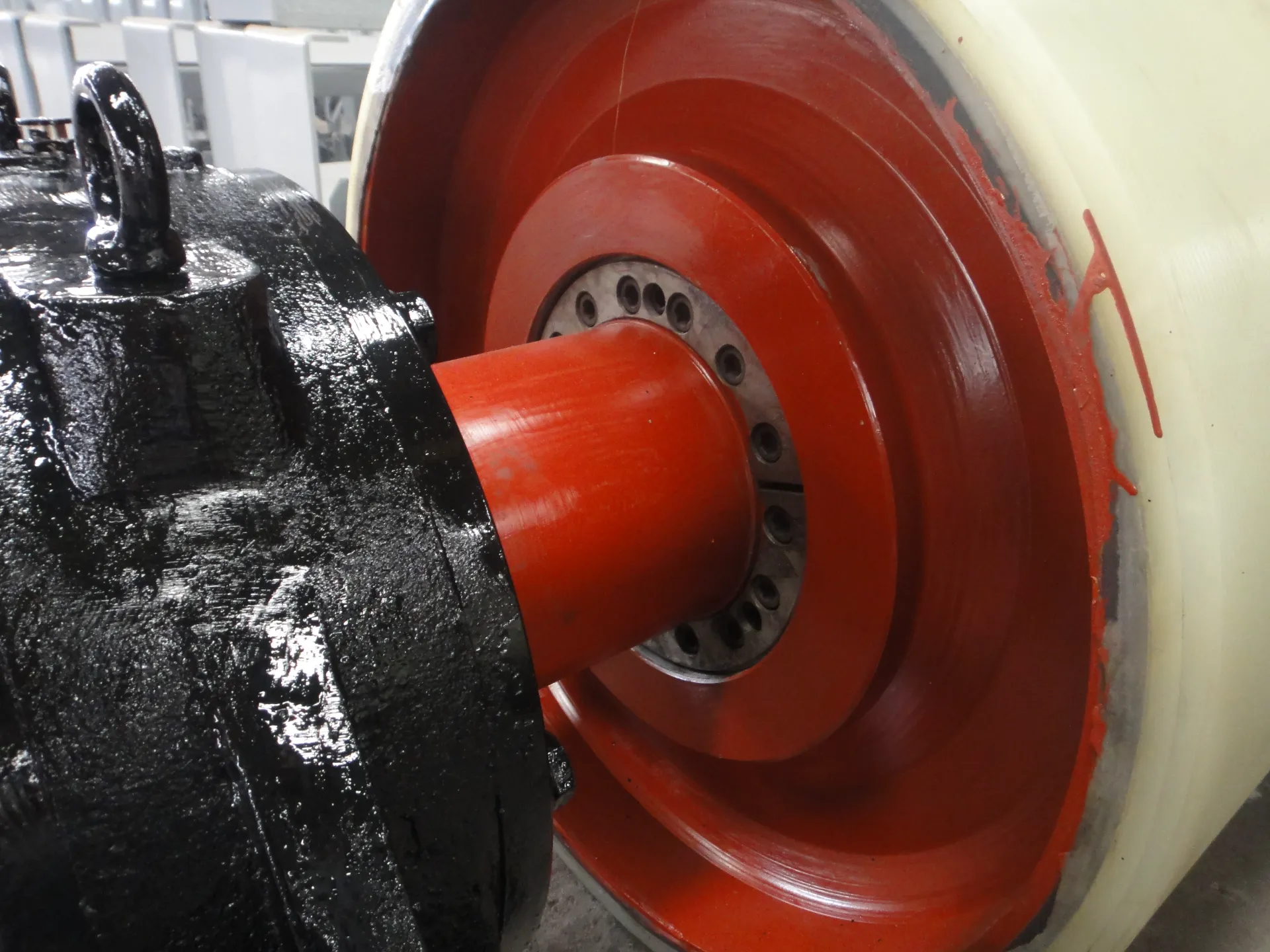

Polyurethane pulley, also known as PU pulley or polyurethane lagging pulley, is widely used in modern industry. This pulley has become the only choice for many mechanical equipment and transmission systems with its excellent physical properties and durability. Polyurethane material is a polymer material with excellent physical properties. Its unique chemical structure makes it particularly outstanding in terms of wear resistance, corrosion resistance, and aging resistance.

Advantages of polyurethane pulleys

First, the outstanding feature of polyurethane pulleys is their high wear resistance. In the long-term use process, the pulleys of mechanical equipment often face wear problems, and the high wear resistance of polyurethane materials enables it to maintain its structural integrity and normal function under high load and high frequency conditions. In addition, PU pulleys have excellent elasticity and toughness, which enables them to reduce friction and impact when carrying high-intensity work, thereby extending the service life of the equipment. Compared with traditional metal pulleys, the lightweight design of polyurethane pulleys also effectively reduces the overall weight of the equipment, improves energy efficiency and work efficiency.

Secondly, polyurethane lagging pulleys have excellent chemical corrosion resistance. In the industrial production process, pulleys may come into contact with various chemicals, such as acids, alkalis, solvents, etc. The insolubility and stability of polyurethane materials enable it to maintain its physical properties unchanged in harsh chemical environments. In addition, PU pulleys also have good anti-aging properties and are not easily degraded by external environmental factors such as sunlight and oxidation. These characteristics make polyurethane lagging pulleys particularly suitable for work situations that require high standards of chemical resistance and anti-aging performance.

Application of polyurethane pulleys

In specific applications, polyurethane pulleys are widely used in various transmission systems and conveying equipment. For example, in mining machinery, cranes, elevators and conveyor belt systems, polyurethane pulleys play a vital role. These equipment usually operate in high-intensity and high-frequency working environments, which places high demands on the durability and reliability of pulleys. The application of polyurethane pulleys not only improves the overall performance of the equipment, but also effectively reduces maintenance costs. In addition, in some machinery that requires precise operation and high-precision transmission, such as medical equipment and precision instruments, the high stability and low noise characteristics of polyurethane pulleys have also been widely recognized.

With the continuous advancement of technology, the production process and material formulation of polyurethane pulleys are also constantly improving. For example, by adjusting the molecular structure of polyurethane materials, their wear resistance and impact resistance can be further improved. At the same time, the use of advanced processing technology, such as injection molding, extrusion molding, etc., can produce polyurethane pulleys of different specifications and shapes to meet the specific needs of different industries. In addition, the comprehensive performance of polyurethane pulleys can be further enhanced by adding nanomaterials or other high-performance fillers. These technological advances have not only improved the market competitiveness of polyurethane pulleys, but also promoted their application in more fields.

Prospects of polyurethane pulleys

In the future, with the in-depth development of industrial automation and intelligent manufacturing, the demand for high-performance pulleys will continue to increase. Polyurethane pulleys are expected to be used in more industrial fields due to their outstanding comprehensive performance. For example, in emerging technology fields such as robotics, automated production lines, and intelligent logistics systems, polyurethane pulleys can play their outstanding performance advantages. At the same time, as the concepts of environmental protection and sustainable development are deeply rooted in the hearts of the people, the environmental protection characteristics of polyurethane materials, such as recyclability and low pollution, will also become an important driving force for their widespread application. Therefore, the market prospects of polyurethane pulleys are very broad, and their application potential in various industries is also worth looking forward to.

In summary, polyurethane pulleys have become an ideal choice for many industrial equipment and transmission systems due to their excellent wear resistance, chemical corrosion resistance and good physical properties. Its wide application and evolving technology have made it an important player in modern industry. With the continuous advancement of technology and the rapid development of emerging fields, polyurethane pulleys will demonstrate their unique advantages in more industries and application scenarios. We have reason to believe that the future of polyurethane pulleys will be brighter, and its innovation and development will bring more possibilities and convenience to industrial production.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysȘtiriJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsȘtiriJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesȘtiriJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysȘtiriJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerȘtiriJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersȘtiriJul.22,2025