Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

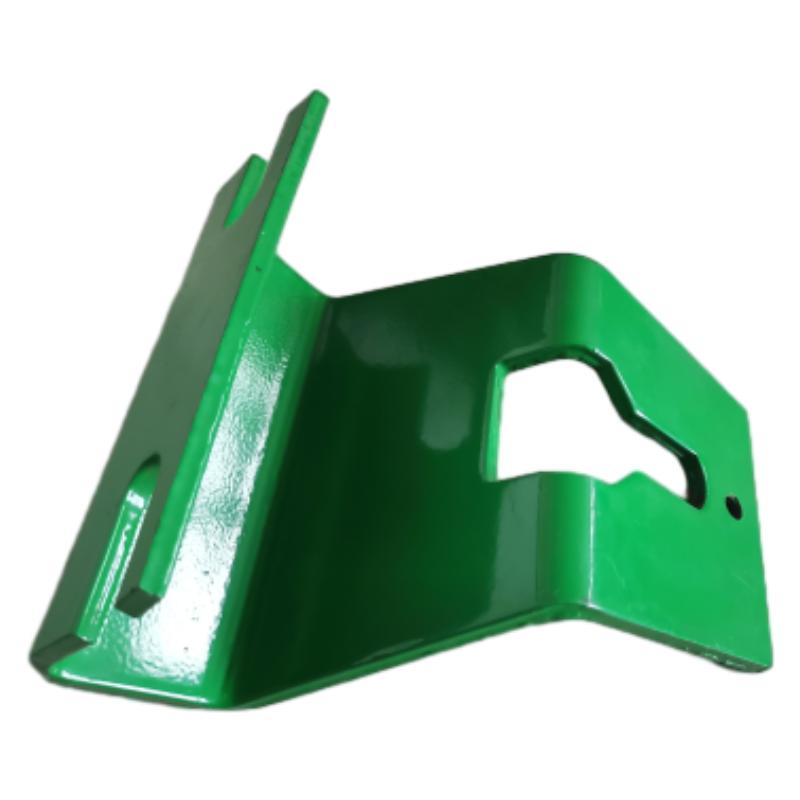

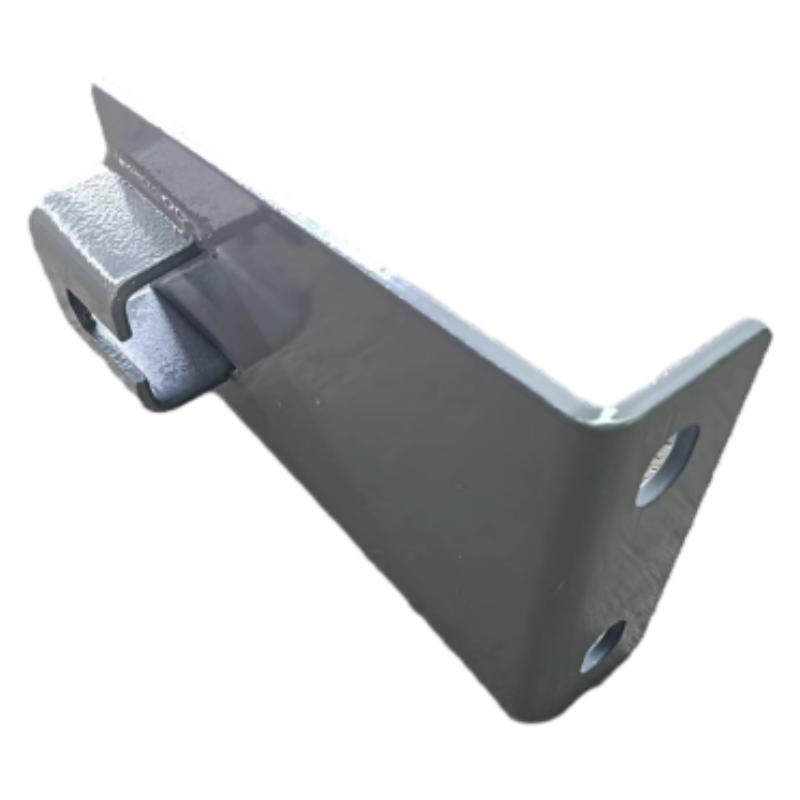

Zulu Durable Return Idler Bracket - Enhanced Belt Tension & Easy Install

In modern materials handling and bulk conveyor systems, the return idler bracket is a crucial component that supports the lower, or "return", belt section of the conveyor. Working hand-in-hand with rollers and brackets, conveyor hangers, and other conveyor roller parts, return idler brackets ensure smooth, low-resistance belt operation, extend belt life, and improve system efficiency.

As global demand for automated, durable, and cost-effective conveyor accessories rises across industries such as mining, petrochemical, metallurgy, and water treatment, idler bracket technology is evolving rapidly.

To maximize both reliability and operational efficiency, selecting the correct return idler bracket requires deep understanding of performance parameters, material grades, and engineering standards.

Below is a technical comparison of standard return idler brackets and related conveyor accessories:

| Parameter | Return Idler Bracket | Conveyor Hanger | Conveyor Roller Parts |

|---|---|---|---|

| Material | Carbon Steel (Q235, 45#), HDG, SS304/316 | Low Carbon Steel, Cast Iron | Polymer, Alloy Steel, Stainless Steel |

| Surface Treatment | HDG, Powder Coated, Epoxy, Dacromet | Galvanized, Painted | Anodization, Rubber Coated |

| Applicable Belt Width | 400–2200 mm | 500–1800 mm | 400–2800 mm |

| Standards | ISO 9001, DIN 22112, ANSI B106.1M | GB/T 10595, ISO 5048 | ISO 1537, CEMA D/E/F |

| Design Life (Avg.) | > 50,000 hours | 30,000 hours | 35,000–60,000 hours |

| Corrosion Resistance | High (Salt Spray ≥ 480h) | Medium | Varies, usually medium |

| Working Temp. | -40°C to +80°C | -20°C to +60°C | -40°C to +120°C |

Key Quality Nodes: Material certification, CNC tolerance control (±0.5mm), weld penetration (≥4mm), and salt spray testing are strictly monitored in accordance with ISO and ANSI conveyor standards for global industry acceptance.

Video illustration: Watch manufacturing process on YouTube (search "idler bracket CNC/galvanizing")

Return idler brackets are seeing major improvements due to:

• Smart design adaptations: 3D parametric design for faster, application-specific customization.

• Enhanced corrosion resistance: Use of HDG and fused epoxy for aggressive chemical exposure scenarios.

• Integration with sensor systems: Newer brackets include mountings for belt misalignment and wear sensors (Smart Conveyors, see BulkInside 2024 Analysis).

• Weight optimization: FE simulation-based design reduces total bracket weight by 12-20% vs. traditional models.

Industry Data: According to Grand View Research, the conveyor components market, including brackets, reached USD 4.95 billion in 2023, with a projected CAGR of 5.7% (2023–2030).

The return idler bracket is widely applied in:

• Mining & Bulk Material Handling: Supports long-belt runs, absorbs vibration. Custom brackets for iron ore, coal, bauxite.

• Petrochemical & Fertilizer: High anti-corrosive surface (epoxy/HDG) ensures durability even with caustic/corrosive transport.

• Water Treatment: Stainless steel brackets are favored for their corrosion resistance.

• Metallurgy: Used in high-temperature, dust-rich environments; brackets featuring special bearings & seals.

Customer Case:

In 2023, a global mining company in Peru (client: Southern Copper Corp.) replaced 1,200 old brackets with RAOHUA’s return idler brackets.

- Belt width: 1600mm

- Bracket material: Q235 HDG (hot-dip galvanized)

- Corrosion resistance increased 3× vs. previous model

- Zero major breakdowns 18 months after installation

Selecting the optimal return idler bracket depends on multiple engineering and operational indicators. Here’s a summary table based on CEMA and ISO guidelines:

| Specification | Typical Value / Range | RAOHUA Model (RH-SG) | Premium Brand A | Premium Brand B |

|---|---|---|---|---|

| Belt Width (mm) | 400-2200 | 400–2000 | 450–1800 | 400–1600 |

| Bracket Thickness (mm) | 6, 8, 10 | 8 | 6 | 8 |

| Surface Treatment | HDG, Powder, Epoxy | HDG, Dacromet | HDG Only | Powder Coating |

| Corrosion Resistance (Salt Spray, h) | ≥480 | ≥720 | 400 | 500 |

| Load Bearing (kg) | 100–220 | 190 | 160 | 170 |

| Industry Certifications | ISO 9001, CE | ISO, ANSI | ISO | ISO, CE |

| Custom Design Availability | Yes | Yes | Partial | No |

RAOHUA delivers OEM/ODM return idler bracket solutions, offering:

- Custom geometry (U-shape, L-shape, reinforced, universal mounting)

- Special coating options (ceramic-filled, epoxy, Poly-Zinc)

- Bracket for high-temp & abrasive applications (fitted for mining, slag, clinker lines)

- Integration with misalignment sensors or monitoring tags (for Smart Plant 4.0 deployment)

- On-site 3D measurement & CAD simulation for retrofit projects

-

Q1: What is the preferred material for high-corrosion environments?

A: For harsh, chemical-rich or coastal applications, SS304/316 stainless steel or heavy-duty hot-dip galvanized (HDG) brackets are recommended due to salt spray resistance & longevity.

-

Q2: What bracket thickness is ideal for mining vs warehouse use?

A: Mining conveyors typically require 8–10 mm thick brackets for impact endurance, while warehouse/conveyance uses 6 mm thickness for cost and weight efficiency.

-

Q3: Which surface treatments exceed 500h salt spray?

A: Hot-dip galvanizing (HDG) generally withstands 480–720h. Epoxy and Dacromet coatings can further enhance to 900h+ in laboratory testing.

-

Q4: What international standards should a quality return idler bracket meet?

A: ISO 9001 (QA), ANSI B106.1M (component spec), DIN 22112 (conveyor component), and CEMA D/E for North America. Compliance ensures global acceptability.

-

Q5: How is custom bracket sizing handled?

A: Most suppliers offer 3D scan or CAD drawing adaptation services. Custom length, height, mounting holes, and surface finish are available—CAD confirmation recommended before mass order.

-

Q6: Are non-destructive tests (NDT) performed?

A: Leading manufacturers implement ultrasonic or magnetic particle NDT on welds and heat-affected zones, verifying strength and absence of hidden defects.

-

Q7: What is typical delivery time for mass production?

A: Normally 10–25 days after drawing confirmation, depending on volume and customizations. Air-freight available for urgent projects, with sea shipping as standard.

| Service | Description |

|---|---|

| Typical Lead Time | 12–25 workdays (custom or bulk orders) |

| Warranty Period | 18–36 months (subject to environment & application) |

| Customer Support | 7 × 24h response, on-site or virtual technical support |

| Quality Commitment | 100% replacement for manufacturing defects within warranty |

| Documentation | Material traceability, inspection certificates, installation guides included |

- The return idler bracket is foundational to modern, reliable, and efficient conveyor systems.

- Material choice, corrosion resistance, and compliance with ISO/ANSI standards are critical for long operational life and project ROI.

- Customization (geometry, coating, load spec) is widely available and recommended for special environments.

- Choose certified suppliers; verify technical data, customer track record, and industry references before purchase.

Bulk-Online Forums: Idler Bracket Discussions

Recent Research: Advances in Conveyor Accessories (ScienceDirect)

CEMA: Belt Conveyors and Components

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025