Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor idler specifications

Understanding Conveyor Idler Specifications Essential Insights for Efficient Material Handling

Conveyor systems are a vital component in various industries, facilitating the smooth movement of materials across different processes. One of the key elements within these systems is the conveyor idler. These components play a crucial role in supporting the conveyor belt, helping to maintain its alignment, and reducing friction as materials are transported. Understanding conveyor idler specifications is critical for optimizing operational efficiency and ensuring long-term reliability.

What Are Conveyor Idlers?

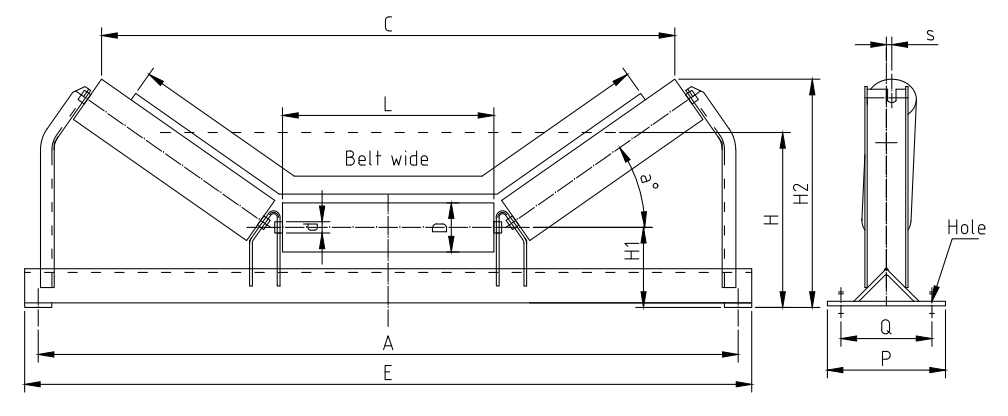

Conveyor idlers are cylindrical components that are mounted on frames, typically aligned parallel to the conveyor belt. They serve multiple functions, such as supporting the weight of the belt and its load, guiding the belt and preventing sagging, and minimizing belt wear through friction reduction. Idlers come in various configurations, depending on their application and the type of materials being transported.

Key Specifications

1. Idler Types Idlers can be classified into several types, including flat, trough, and return idlers. Flat idlers are primarily used for light-duty applications, while trough idlers are designed to carry bulk materials and provide better load containment. Return idlers serve the purpose of guiding the belt as it returns to the loading point.

2. Roll Diameter The diameter of the idler roll significantly affects the performance of the conveyor system. Standard diameters range from 4 inches to 8 inches, with larger diameters generally being more effective for heavy loads. A larger diameter reduces the bending stress on the belt and provides better support for the conveyed materials.

conveyor idler specifications

3. Roll Length The width of the idler roll should match the width of the conveyor belt to ensure proper loading and to prevent spillage of materials. Idler lengths typically range from 20 inches to over 60 inches, with longer rolls used for wider belts. Proper selection of roll length is crucial for maintaining belt alignment and preventing uneven wear.

4. Material and Construction Idlers are usually constructed from steel, although plastic and rubber materials may also be used for specific applications. Steel idlers are durable and suitable for heavy loads, while plastic idlers may be better for environments where corrosion is a concern. The construction must ensure strength and resistance to wear and tear under various operating conditions.

5. Bearing Types The bearings used in idlers can be either standard or sealed. Standard bearings require regular maintenance and lubrication, which can be time-consuming. Sealed bearings, on the other hand, are maintenance-free and last longer, making them a popular choice for many applications.

6. Frame and Mounting The frame that supports the idler must be robust enough to handle the loads and stresses exerted on it during operation. Proper mounting of the idler is also critical to ensure that the conveyor belt maintains optimal alignment and tension.

Importance of Specifications

Selecting the right conveyor idler specifications is essential for maximizing the efficiency and lifespan of a conveyor system. Properly configured idlers reduce operational costs by minimizing wear on the belt and decreasing energy consumption. Additionally, understanding the specifications helps in achieving better material flow and reducing downtime for maintenance.

In conclusion, comprehensive knowledge of conveyor idler specifications—including type, roll diameter, roll length, material, bearing type, and mounting—is vital for anyone involved in material handling. By choosing the right idlers tailored to specific operational needs, companies can enhance productivity, minimize costs, and ensure a smooth and reliable material handling process. Making informed decisions about idler specifications is not just an engineering concern; it is a strategic approach to achieving operational excellence in any industrial setting.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025