Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu ਫਰ. . 19, 2025 02:28

Back to list

types of take up pulley

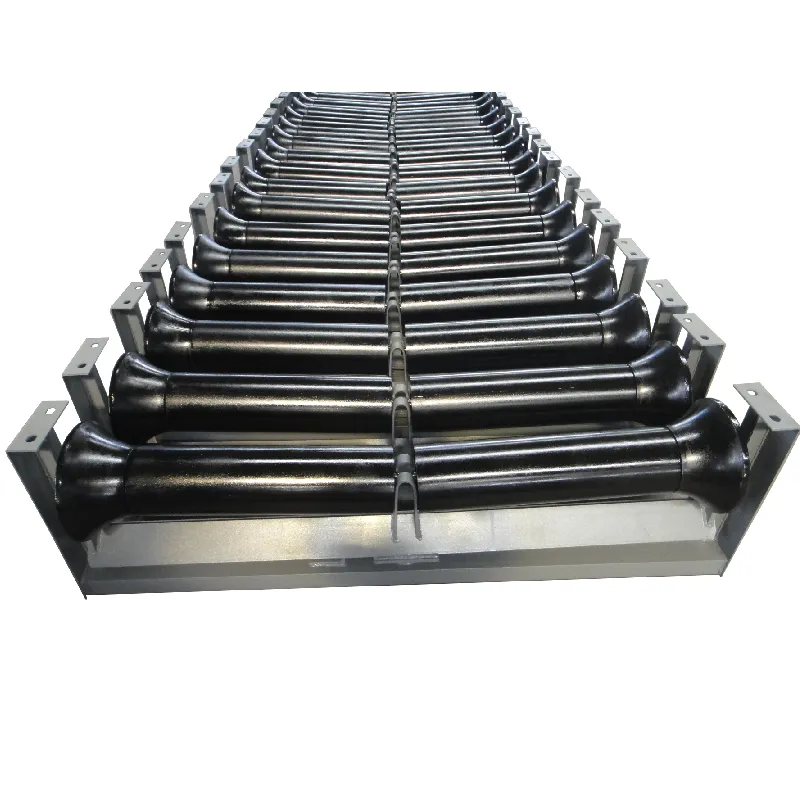

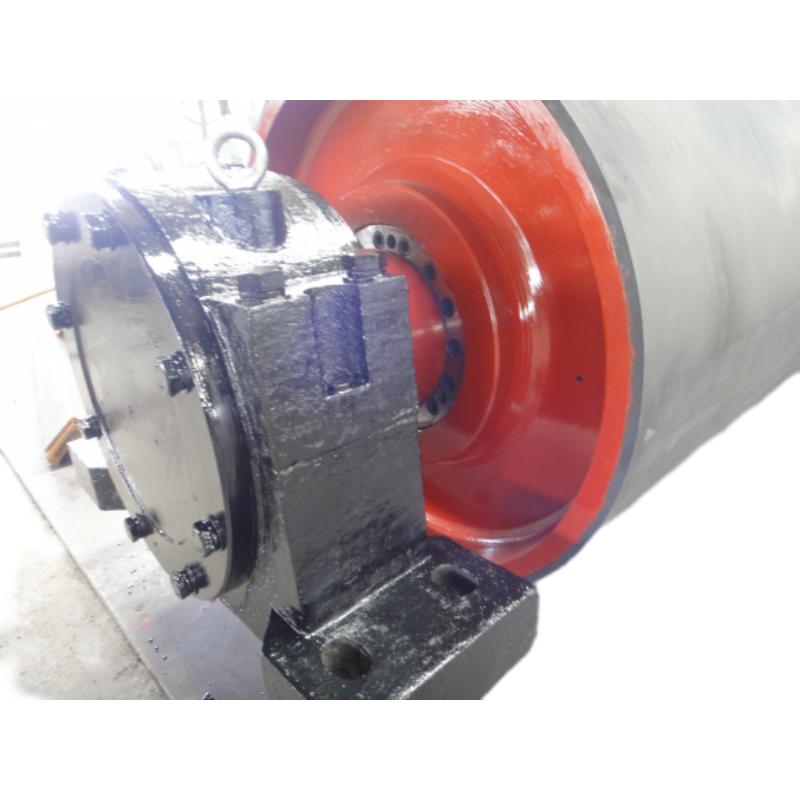

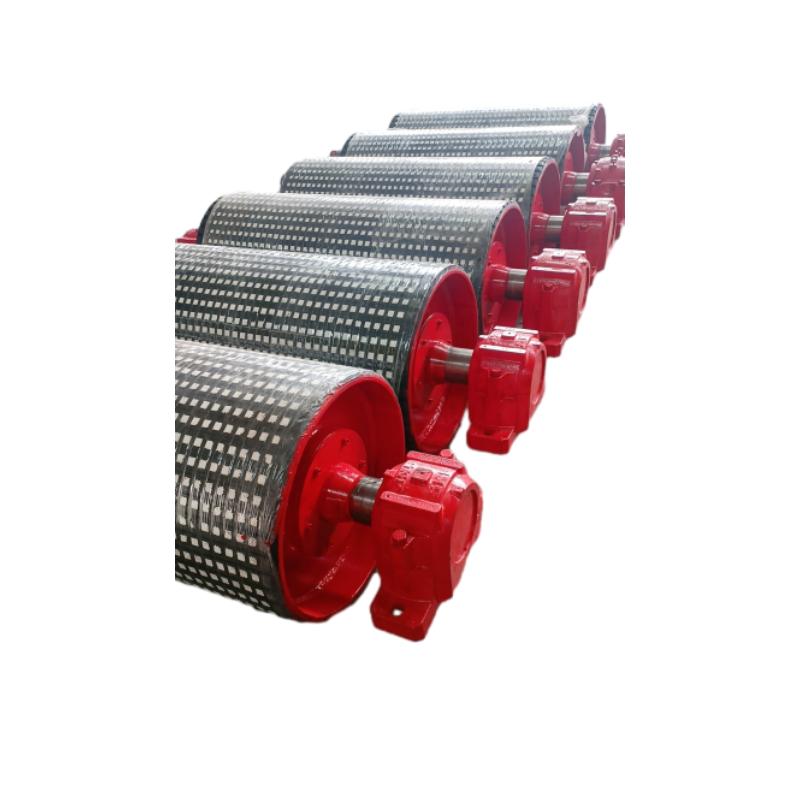

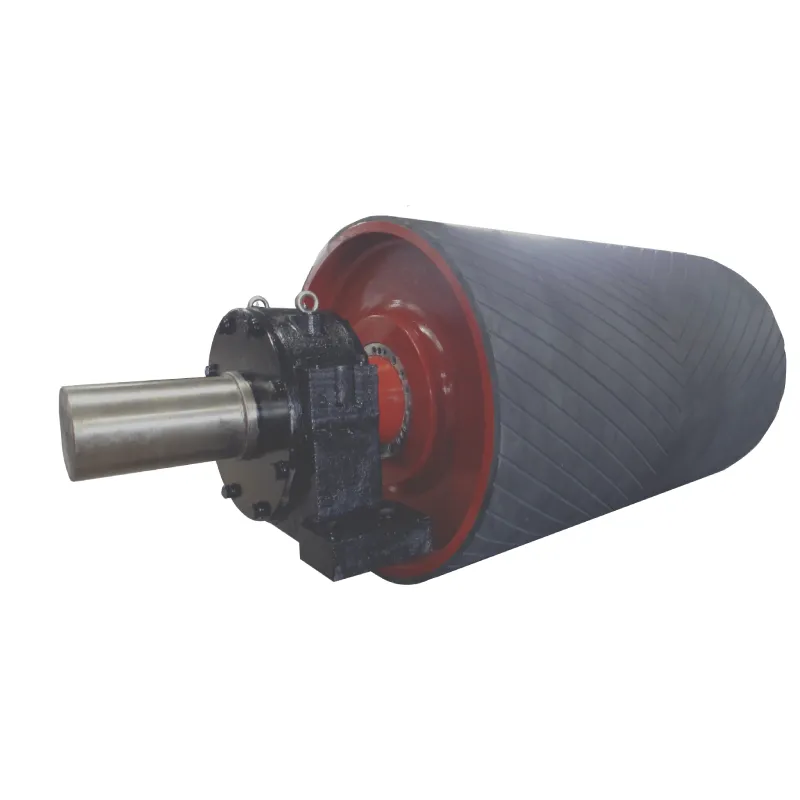

The world of industrial machinery involves intricate systems that must run smoothly to ensure efficiency and productivity. One critical component in various conveyor systems is the take-up pulley. These devices maintain tension within the belt, ensuring it functions correctly over extended periods. Understanding the different types of take-up pulleys available can provide significant advantages in optimizing a system’s performance.

4. Spring-Loaded Take-Up Pulley Systems In this configuration, springs are used to apply tension to the pulley, which then adjusts the belt as needed. The spring mechanism provides automatic tension adjustments, similar to gravity systems, but can be more compact. This system suits environments with limited space or where frequent tension adjustments are necessary. It offers a balance between the simplicity of gravity systems and the precision of screw systems. Selecting the right take-up pulley involves evaluating the operational demands of the system, the maintenance resources available, and the desired level of automation. Each type of system has its advantages and disadvantages, and the choice may ultimately come down to specific operational criteria and environmental conditions. Maintaining the right tension in a conveyor belt is crucial not just for the efficiency of operations but also for the safety of the system. Proper tension avoids problems such as slippage, excessive wear, and misalignment, which can lead to costly downtime and repairs. Integrating the right take-up pulley system can dramatically improve the performance and reliability of your conveying equipment. When considering upgrades or new installations, consulting with industry experts can ensure that you select a system that optimally balances efficiency and cost-effectiveness, aligning with your operational goals.

4. Spring-Loaded Take-Up Pulley Systems In this configuration, springs are used to apply tension to the pulley, which then adjusts the belt as needed. The spring mechanism provides automatic tension adjustments, similar to gravity systems, but can be more compact. This system suits environments with limited space or where frequent tension adjustments are necessary. It offers a balance between the simplicity of gravity systems and the precision of screw systems. Selecting the right take-up pulley involves evaluating the operational demands of the system, the maintenance resources available, and the desired level of automation. Each type of system has its advantages and disadvantages, and the choice may ultimately come down to specific operational criteria and environmental conditions. Maintaining the right tension in a conveyor belt is crucial not just for the efficiency of operations but also for the safety of the system. Proper tension avoids problems such as slippage, excessive wear, and misalignment, which can lead to costly downtime and repairs. Integrating the right take-up pulley system can dramatically improve the performance and reliability of your conveying equipment. When considering upgrades or new installations, consulting with industry experts can ensure that you select a system that optimally balances efficiency and cost-effectiveness, aligning with your operational goals.

Next:

Latest news

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025

OUR PRODUCTS