Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu spiral return idler

Understanding Spiral Return Idlers Importance and Applications

In the world of conveyor systems, components play a crucial role in ensuring smooth and efficient operations. One such essential component is the spiral return idler. Designed specifically to support and facilitate the return of conveyor belts, spiral return idlers contribute significantly to the overall performance and longevity of conveyor systems.

What is a Spiral Return Idler?

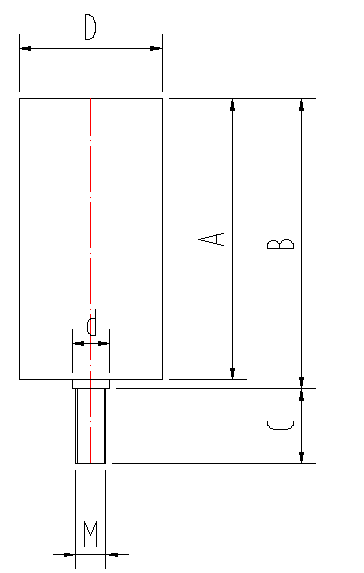

A spiral return idler is a type of conveyor idler characterized by the helical arrangement of its rollers. These idlers are typically used in conveyor systems that transport bulk materials, such as minerals, grains, and other industrial products. The design allows for effective belt support while minimizing the wear and tear that can result from belt misalignment or friction against the frame. Unlike traditional flat return idlers, spiral return idlers provide a more efficient path for the return conveyor belt, helping to reduce material accumulation and maintenance issues.

Key Features and Benefits

One of the primary advantages of using spiral return idlers is their ability to enhance the performance of the conveyor system. The spiral design allows the idler to support the belt in a way that reduces friction between the belt and the idler. This results not only in lower energy consumption but also in less stress on the conveyor components, extending their operational life.

spiral return idler

Another notable feature is the idler's ability to effectively handle the return path of the belt, minimizing the chances of belt sagging or misalignment. This ensures that the conveyor operates smoothly, reduces the risks of unexpected downtimes, and improves efficiency. Additionally, spiral return idlers can also help in the dispersion of materials on the return belt, minimizing blockages or buildup that can disrupt operations.

Applications of Spiral Return Idlers

Spiral return idlers find utility in various industries, particularly those that rely heavily on bulk material handling. They are commonly used in sectors such as mining, agriculture, construction, and power generation. In mining operations, for example, they support long conveyor systems that transport ores and minerals, ensuring consistent material flow while minimizing wear on the equipment.

In agricultural settings, spiral return idlers can be found in grain handling systems, where they facilitate the efficient transport of grains from one point to another. Similarly, in construction, these idlers are used in conveyor systems that move sand, gravel, or other bulk materials, ensuring that operations run smoothly.

Conclusion

In summary, spiral return idlers play a vital role in the effective operation of conveyor systems across a multitude of industries. Their unique design not only supports the return path of the conveyor belt but also enhances efficiency, reduces maintenance costs, and extends the lifespan of conveyor components. Understanding the significance of spiral return idlers can help businesses optimize their material handling processes, ultimately leading to improved productivity and reduced operational costs. As technology advances, the design and materials used in these components are likely to evolve, further enhancing their effectiveness and efficiency in various applications.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025