Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu industrial conveyor belt rollers

The Importance of Industrial Conveyor Belt Rollers

In modern manufacturing and logistics, efficiency is key to maintaining competitiveness. One critical component often overlooked in the design and implementation of conveyor systems is the conveyor belt roller. These essential parts facilitate the smooth operation of conveyor belts, enabling the transport of goods across various industries.

Understanding Conveyor Belt Rollers

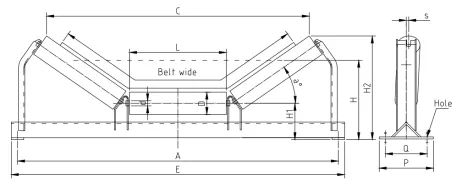

Conveyor belt rollers, also known as conveyor rollers, provide support and facilitate the movement of the conveyor belt, allowing for the effective transportation of materials. These rollers are strategically placed along the length of the conveyor system, assisting in reducing friction and wear on the belt while increasing the overall efficiency of the transport process.

There are several types of conveyor rollers, each designed for specific applications. The most common types include

1. Idler Rollers These are inactive rollers that support the belt and contribute to its tension. They are crucial for maintaining belt alignment and ensuring a smooth flow of materials.

2. Drive Rollers These rollers are connected to the motor and help drive the belt forward. Their design and material are pivotal as they must withstand varying loads and resist wear.

3. Guide Rollers Primarily used to maintain the proper alignment of the belt, guide rollers are imperative for ensuring the longevity of the conveyor system, particularly in industries such as mining and quarrying where materials can be abrasive.

The Role of Conveyor Belt Rollers in Industry

In industries such as manufacturing, warehousing, and mining, conveyor belt rollers play a significant role in enhancing operational efficiency. They reduce manual labor and minimize the time taken to move materials. With the integration of conveyor systems that utilize high-quality rollers, companies can maximize productivity and reduce downtime caused by transportation bottlenecks.

Furthermore, rollers contribute to safety within the workplace. A well-maintained conveyor system minimizes the risk of accidents associated with material handling. Properly functioning rollers help to prevent belt misalignment, which can lead to spills or equipment malfunction. Consequently, this reduces workplace hazards and enhances overall safety for employees.

industrial conveyor belt rollers

Material and Design Considerations

The design of conveyor belt rollers is crucial for their performance and longevity. Rollers are typically made from materials that can withstand harsh environments, including high temperatures, corrosive substances, and heavy loads. Common materials used include

- Steel Known for its strength and durability, steel rollers are ideal for heavy-duty applications. However, they may require protective coatings to prevent rust and corrosion.

- Plastic Lighter and resistant to corrosion, plastic rollers can be advantageous in environments where chemical resistance is needed.

- Aluminum This material offers a good balance between weight and strength, making aluminum rollers suitable for various light to medium-duty applications.

The design of the roller is also important. Features such as diameter, bearing type, and surface finish can significantly affect the roller's performance and lifespan. A thoughtful design helps in minimizing vibrations and noise, contributing to a smoother operational environment.

Maintenance and Longevity

To ensure the longevity of conveyor belt rollers, regular maintenance is essential. This includes checking for wear and tear, lubricating bearings, and ensuring that rollers are properly aligned. Preventative maintenance can significantly reduce downtime and extend the life of both the rollers and the conveyor belt.

Additionally, industries should invest in high-quality rollers from reputable manufacturers. Cost-cutting on these components can lead to frequent replacements and operational inefficiencies.

Conclusion

In conclusion, conveyor belt rollers are a fundamental component of industrial conveyor systems. Their role in supporting the conveyor belt and facilitating material transport cannot be overstated. By understanding the different types of rollers, their materials, and the importance of proper maintenance, industries can enhance their operational efficiency and safety. As technology evolves, ongoing innovation in roller design and materials will continue to shape the future of industrial conveyor systems, ensuring they remain a vital part of manufacturing and logistics challenges. Investing in high-quality conveyor belt rollers is not only a matter of improved performance but also a commitment to safety and sustainability in operations.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025