Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Optimal Solutions for Conveyor Bracket Design and Installation Techniques

Understanding Conveyor Brackets Essential Components for Conveyor Systems

Conveyor systems are integral to various industries, ensuring the efficient movement of goods and materials. Among the many components that contribute to the functionality of these systems, conveyor brackets play a crucial role. These brackets serve as support elements that secure and align different parts of the conveyor system, ensuring smooth operation and reliability.

What are Conveyor Brackets?

Conveyor brackets are structural components designed to support and stabilize conveyor belts, rollers, and other crucial elements of a conveyor system. They are typically made from durable materials like steel or aluminum, enabling them to withstand the mechanical stresses involved in transporting heavy loads. These brackets come in various shapes and sizes to fit different conveyor designs and applications.

The Importance of Conveyor Brackets

1. Structural Integrity Conveyor brackets provide the necessary support to maintain the alignment of the conveyor system. Proper alignment is essential to prevent wear and tear, reduce the risk of malfunction, and extend the system's lifespan.

2. Load Distribution By securing different components, brackets help distribute the weight of the materials being transported. This distribution is vital, especially in high-load situations, as it minimizes the risk of sagging or other structural failures that could lead to operational downtime.

3. Ease of Maintenance Well-designed conveyor brackets facilitate easier access to various conveyor components for maintenance and repairs. This aspect is vital for reducing downtime and ensuring that any issues can be addressed swiftly.

4. Versatility Conveyor brackets can be customized or adjusted to fit specific needs. Whether it’s a lightweight conveyor for delicate items or a heavy-duty system for transporting bulk materials, there are brackets available to meet the demands of various applications.

Types of Conveyor Brackets

Conveyor brackets come in different forms, each serving particular functions within the conveyor system

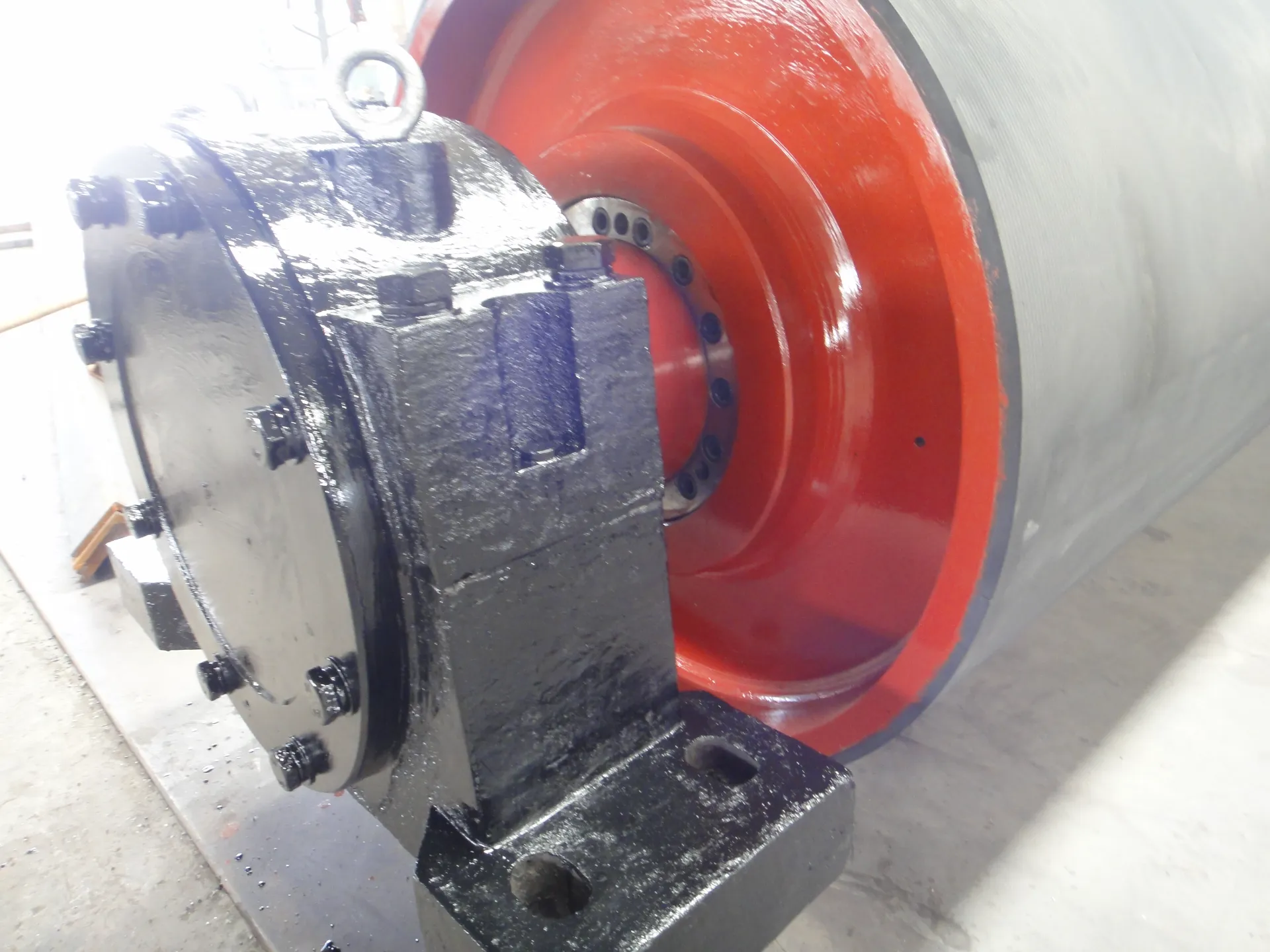

1. Mounting Brackets These brackets support primary components like motors and rollers. They are critical for ensuring that these elements remain securely in place during operation.

conveyor brackets

2. Side Brackets Often used to hold the sides of the conveyor belt in place, side brackets help maintain proper alignment, preventing the belt from drifting.

3. Support Brackets These are used to provide additional support at various points along the conveyor system, particularly in long stretches where sagging is a concern.

4. Adjustable Brackets Designed to provide flexibility, adjustable brackets allow users to modify their positions according to specific load requirements or changes in the conveyor system.

Choosing the Right Conveyor Brackets

When selecting conveyor brackets, several factors must be considered

- Load Capacity Understanding the weight and type of material being transported is crucial. Brackets need to be strong enough to handle the specific loads without bending or breaking.

- Material Compatibility The materials used for brackets should be chemically resistant if transporting corrosive substances or designed to handle specific temperature ranges if working in extreme environments.

- Installation Requirements The ease of installation can significantly impact operational efficiency. Some brackets are designed for quick attachment, while others may require more complex setup.

- Environmental Conditions Depending on the operating environment, brackets may need to resist factors such as moisture, dust, and extreme temperatures. Selecting the right type can enhance performance and longevity.

Conclusion

The role of conveyor brackets in the overall efficiency and reliability of conveyor systems cannot be overstated. They are vital for maintaining structural integrity, optimizing load distribution, and facilitating maintenance. As industries increasingly rely on automated systems for material handling, understanding and choosing the right conveyor brackets will be essential for maximizing efficiency and minimizing disruptions. Investing in high-quality conveyor brackets not only enhances the performance of the conveyor system but also contributes to the long-term success of operational processes. Whether in manufacturing, warehousing, or distribution, conveyor brackets are the unsung heroes that keep the wheels of industry turning smoothly.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025