Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor bearing housing

The Importance of Conveyor Bearing Housing in Material Handling Systems

In the realm of material handling, efficient and reliable systems are paramount to ensuring smooth operations in industries ranging from manufacturing to logistics. One of the critical components that contribute to the overall efficiency of conveyor systems is the conveyor bearing housing. This seemingly simple structure plays a significant role in supporting and protecting the bearings that allow conveyors to operate effectively.

Understanding Conveyor Bearing Housing

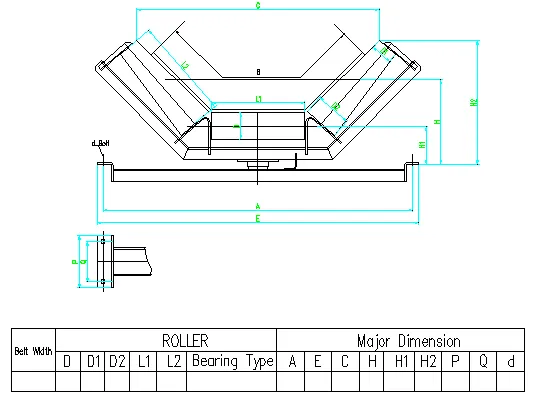

Conveyor bearing housing is designed to house bearings that facilitate the movement of conveyor belts. These housings are typically constructed from durable materials such as cast iron, aluminum, or plastic, depending on the application and environmental conditions. The purpose of the bearing housing is twofold it provides structural support to the bearings and ensures that they remain positioned correctly throughout the operation.

The importance of maintaining the correct alignment and support for bearings cannot be overstated. Misaligned or poorly supported bearings can lead to increased friction, excessive wear, and ultimately, premature failure of the conveyor system. This can result in costly downtime, reduced efficiency, and increased maintenance expenses.

Key Features of Conveyor Bearing Housing

1. Material Durability The choice of material for bearing housings is crucial. Cast iron is often used for its exceptional strength and shock-absorbing capabilities, while aluminum offers a lighter, corrosion-resistant alternative. Plastic housings are also available, particularly in environments where weight reduction is a priority and exposure to harsh chemicals is a concern.

2. Sealing Mechanisms Conveyor bearing housings are equipped with sealing mechanisms that protect the bearings from dust, debris, and moisture. These seals help maintain the integrity of the lubricant inside the housing, reducing friction and wear over time.

3. Accessibility Many modern bearing housings are designed with accessibility in mind. Features such as removable covers and easy-to-replace bearings allow maintenance personnel to conduct inspections and repairs without extensive disassembly of the conveyor system.

conveyor bearing housing

4. Design Flexibility Conveyor systems come in various shapes and sizes, and bearing housings are often customized to fit specific applications. This flexibility allows for optimal integration into existing systems, ensuring that all components work together seamlessly.

Maintenance and Care

To maximize the longevity and efficiency of conveyor bearing housing, regular maintenance is essential. Operators should develop a routine inspection schedule to look for signs of wear, misalignment, and contamination. Here are some best practices for maintaining conveyor bearing housings

- Regular Lubrication Proper lubrication helps reduce friction and prevents overheating. Ensure that the bearings are adequately lubricated according to the manufacturer’s specifications.

- Temperature Monitoring Keep an eye on the temperature of the bearings and housing during operation. Unusual temperature spikes can indicate potential issues that need to be addressed before they lead to failure.

- Visual Inspections Conduct regular visual inspections to identify any signs of wear or damage. Look for cracks or deformities in the housing and check the seals for signs of deterioration.

- Alignment Checks Ensure that the conveyor system is properly aligned. Misalignment can lead to uneven wear on the bearings and premature failure of the housing.

Conclusion

In summary, conveyor bearing housing is a vital component in the efficiency and reliability of conveyor systems. Its ability to protect and support bearings means that it directly influences the overall performance and durability of material handling operations. By investing in quality bearing housings and implementing a proactive maintenance strategy, organizations can minimize downtime, reduce operational costs, and enhance productivity. As industries continue to evolve and demand more from their material handling systems, the importance of conveyor bearing housing will only continue to grow. Ensuring the optimal performance of these components is essential for maintaining a competitive edge in today’s market.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025