Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

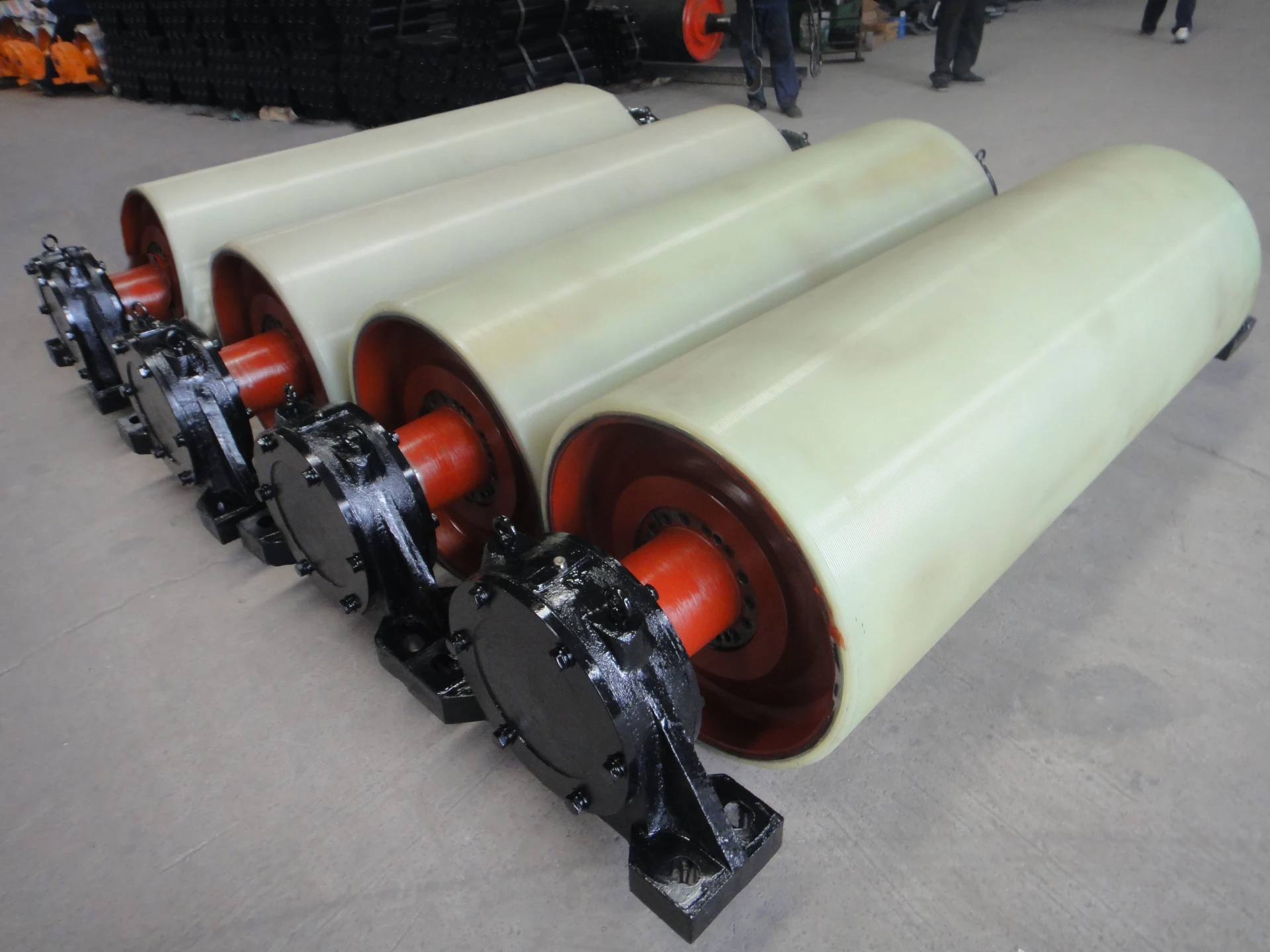

Zulu Rubber Conveyor Belt Rollers for Efficient Material Handling Solutions

Understanding Rubber Conveyor Belt Rollers Essential Components for Efficient Material Handling

Rubber conveyor belt rollers play a crucial role in the transportation of goods across various industries, including mining, manufacturing, and logistics. These rollers are integral components of conveyor systems, helps facilitate the smooth movement of materials while reducing friction and wear, thereby enhancing operational efficiency. This article will explore the significance, types, maintenance, and innovations related to rubber conveyor belt rollers.

Importance of Rubber Conveyor Belt Rollers

Conveyor belt rollers serve multiple functions in a conveyor system. Primarily, they support the weight of the conveyor belt and the materials being transported, ensuring that the entire assembly operates effectively. By distributing the weight evenly, these rollers minimize strain on other components, promoting longevity and reliability. Moreover, they help maintain proper tension and alignment of the conveyor belt, which is essential for preventing misalignment and operational breakdowns.

Types of Rubber Conveyor Belt Rollers

Rubber conveyor belt rollers come in various types, each designed for specific applications and environments. Here are a few common types

1. Idler Rollers These rollers support the belt and maintain its tension. They are vital for ensuring that the belt remains in position as it transports materials.

2. Drive Rollers Located at the conveyor's end, these rollers provide the necessary power to move the belt. They are usually equipped with a motor to facilitate movement.

3. Return Rollers Positioned on the underside of the conveyor system, return rollers help guide the belt back to its starting point after it has offloaded its materials. This helps maintain an uninterrupted flow of materials.

4. Impact Rollers These rollers are designed to handle the shock of heavy loads, especially when materials are dropped onto the conveyor belt. Their padded surfaces absorb impact, preventing damage to the belt and rollers.

5. Self-Cleaning Rollers Equipped with mechanisms to remove debris and materials that may adhere to them, self-cleaning rollers are an innovative solution to minimize maintenance and enhance efficiency.

Maintenance of Rubber Conveyor Belt Rollers

rubber conveyor belt rollers

Maintaining rubber conveyor belt rollers is essential for ensuring the longevity and efficiency of the conveyor system. Regular inspection and proactive maintenance practices can prevent costly downtime and repairs. Here are several maintenance tips

- Routine Inspections Regularly check for signs of wear and tear, such as cracks, warping, or misalignment. Addressing these issues early can prevent equipment failure.

- Lubrication Ensure that the bearings of the rollers are adequately lubricated to reduce friction and wear. This will prolong the life of both the rollers and the conveyor belt.

- Replacement of Damaged Rollers Any roller that shows extensive damage should be replaced immediately to avoid impacting the overall conveyor system performance.

- Cleaning Keep the rollers clean from dust, debris, and leftover materials. A clean roller is less likely to experience issues with operational efficiency.

Innovations in Rubber Conveyor Belt Rollers

Technology continues to advance, leading to the development of innovative roller designs. Current trends include

- Lightweight Materials Some manufacturers are now using advanced composites that reduce the weight of rollers while retaining strength, making them easier to install and maintain.

- Enhanced Durability New rubber compounds and materials are being formulated to enhance resistance to wear, chemicals, and extreme temperatures, thus extending the life of conveyor belt rollers.

- Smart Technology The integration of sensors and smart technology in rollers is emerging. These systems can monitor conditions in real time, allowing for predictive maintenance and minimizing unplanned downtime.

Conclusion

Rubber conveyor belt rollers are essential components that significantly affect the efficiency and reliability of conveyor systems. Understanding their types, maintenance requirements, and the latest innovations can help industries optimize their operations and prolong the life of their equipment. By investing in high-quality rollers and adhering to a regular maintenance routine, businesses can ensure a smooth and seamless material handling process.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025