Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

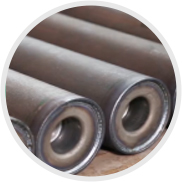

Zulu polyurethane v roller

The Advantages of Polyurethane V Rollers

Polyurethane V rollers are essential components in various industrial applications, known for their durability, versatility, and performance. This article explores the benefits of polyurethane V rollers, their applications, and why they have become a preferred choice over traditional materials.

Durability and Longevity

One of the standout features of polyurethane V rollers is their exceptional durability. Polyurethane is a synthetic material known for its impressive resistance to wear and tear, making it ideal for high-load and high-friction environments. These rollers can withstand harsh conditions, including extreme temperatures, UV exposure, and chemical agents, which often cause traditional rubber or plastic rollers to degrade rapidly. This resilience means that industries can reduce maintenance costs and downtime, as polyurethane V rollers last significantly longer than their counterparts.

Reduced Noise Levels

In many industrial settings, noise pollution can be a significant concern. Polyurethane rollers are designed to operate quietly, offering a smoother and more pleasant working environment. Their ability to absorb shocks and vibrations significantly reduces noise levels during operation. This characteristic is particularly beneficial in manufacturing facilities, warehouses, and distribution centers where excessive noise can lead to distractions and decreased productivity.

Enhanced Performance

Polyurethane V rollers exhibit excellent grip and traction, making them ideal for conveyor systems and material handling applications. The unique properties of polyurethane allow these rollers to maintain their shape under pressure, ensuring consistent performance. The design of V rollers helps to stabilize loads and guide materials efficiently along conveyor belts, minimizing the risk of slipping or misalignment. This enhancement in operational performance translates to improved throughput and overall efficiency in industrial processes.

polyurethane v roller

Versatility Across Industries

Polyurethane V rollers find applications in numerous industries, from packaging and logistics to manufacturing and automotive. Their versatility allows them to be used in a range of equipment, including conveyors, sorting systems, and automated guided vehicles (AGVs). As industries continue to evolve, the demand for reliable and efficient components like polyurethane V rollers is only likely to increase.

Customization Options

Another significant benefit of polyurethane V rollers is the availability of customization options. Manufacturers can produce rollers in various sizes, shapes, and hardness levels to meet specific operational requirements. This ability to tailor products ensures that companies can find the perfect roller for their needs, optimizing their processes and enhancing overall equipment performance.

Sustainable Choice

In today's environment-conscious world, the sustainability of materials used in manufacturing is increasingly important. Polyurethane is known for its recyclable properties, making polyurethane V rollers a more sustainable choice compared to other materials. By opting for these rollers, businesses can decrease their environmental footprint while still enjoying the performance benefits they provide.

Conclusion

In summary, polyurethane V rollers offer a range of advantages that make them an essential component in various industrial applications. Their durability, reduced noise levels, enhanced performance, versatility, customization options, and sustainability make them a superior choice for businesses looking to improve efficiency and reduce maintenance costs. As industries continue to evolve, embracing innovative materials like polyurethane will be crucial in driving productivity and sustainability forward.