Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jun . 27, 2024 01:00

Back to list

Industrial Equipment Conveyor Belt Scrapers for Material Handling

Conveyor Belt Scrapers Essential for Efficient Material Handling

In the vast world of material handling, conveyor belts play a crucial role in transporting goods from one place to another. However, over time, these belts can accumulate debris and materials, leading to reduced efficiency and potential damage to the belt itself. This is where conveyor belt scrapers come into play, serving as an indispensable tool for maintaining optimal performance and extending the life of conveyor systems.

Conveyor belt scrapers are designed to remove adhering materials from the belt surface with precision and efficiency. These scrapers are typically made of high-quality materials such as rubber or polyurethane, which provide durability and resistance to wear and tear. They are mounted on a bracket or frame and positioned strategically along the belt path to ensure maximum contact with the belt surface.

One of the key benefits of using conveyor belt scrapers is their ability to improve the overall efficiency of material handling operations. By removing debris and materials that can cause slippage and jammed belts, scrapers help maintain consistent belt speed and reduce downtime. This, in turn, leads to increased productivity and cost savings for businesses.

Another important aspect of conveyor belt scrapers is their ability to extend the life of conveyor belts

Another important aspect of conveyor belt scrapers is their ability to extend the life of conveyor belts Another important aspect of conveyor belt scrapers is their ability to extend the life of conveyor belts

Another important aspect of conveyor belt scrapers is their ability to extend the life of conveyor belts

Another important aspect of conveyor belt scrapers is their ability to extend the life of conveyor belts

Another important aspect of conveyor belt scrapers is their ability to extend the life of conveyor belts conveyor belt scraper. Over time, accumulated debris and materials can cause wear and tear on the belt, leading to premature failure. By regularly removing these materials, scrapers help prevent damage and extend the life of the belt, reducing replacement costs and maintenance downtime.

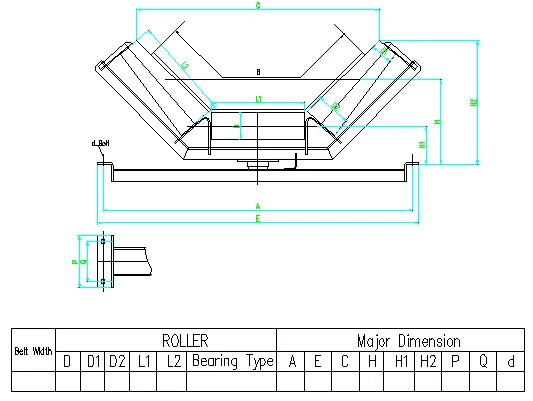

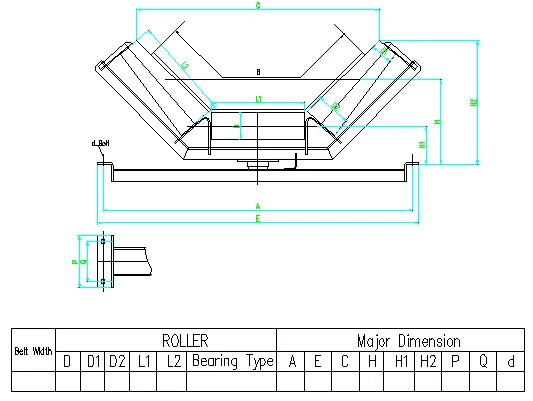

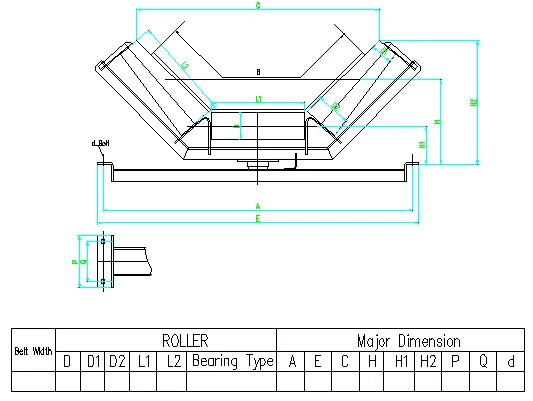

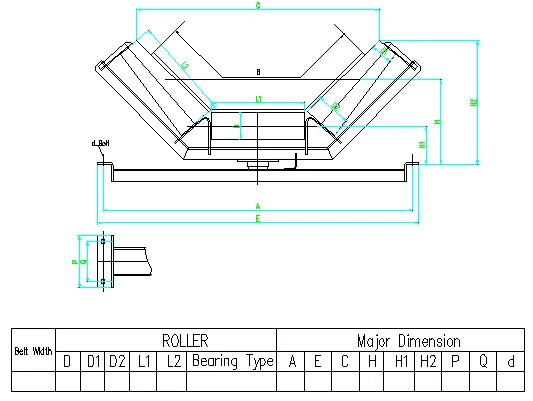

Moreover, conveyor belt scrapers can be customized to fit various conveyor systems and applications. Different types of scrapers are available for different belt widths, speeds, and materials being transported. This flexibility allows businesses to select the most suitable scraper for their specific needs, ensuring optimal performance and reliability.

In conclusion, conveyor belt scrapers are a vital component of any material handling system. Their ability to remove adhering materials, improve efficiency, extend belt life, and customize to suit various applications make them an essential investment for businesses seeking to optimize their material handling operations. By incorporating scrapers into their conveyor systems, businesses can enjoy increased productivity, reduced downtime, and lower maintenance costs, resulting in a more efficient and profitable operation.

conveyor belt scraper. Over time, accumulated debris and materials can cause wear and tear on the belt, leading to premature failure. By regularly removing these materials, scrapers help prevent damage and extend the life of the belt, reducing replacement costs and maintenance downtime.

Moreover, conveyor belt scrapers can be customized to fit various conveyor systems and applications. Different types of scrapers are available for different belt widths, speeds, and materials being transported. This flexibility allows businesses to select the most suitable scraper for their specific needs, ensuring optimal performance and reliability.

In conclusion, conveyor belt scrapers are a vital component of any material handling system. Their ability to remove adhering materials, improve efficiency, extend belt life, and customize to suit various applications make them an essential investment for businesses seeking to optimize their material handling operations. By incorporating scrapers into their conveyor systems, businesses can enjoy increased productivity, reduced downtime, and lower maintenance costs, resulting in a more efficient and profitable operation.

Another important aspect of conveyor belt scrapers is their ability to extend the life of conveyor belts

Another important aspect of conveyor belt scrapers is their ability to extend the life of conveyor belts

Another important aspect of conveyor belt scrapers is their ability to extend the life of conveyor belts

Another important aspect of conveyor belt scrapers is their ability to extend the life of conveyor belts conveyor belt scraper. Over time, accumulated debris and materials can cause wear and tear on the belt, leading to premature failure. By regularly removing these materials, scrapers help prevent damage and extend the life of the belt, reducing replacement costs and maintenance downtime.

Moreover, conveyor belt scrapers can be customized to fit various conveyor systems and applications. Different types of scrapers are available for different belt widths, speeds, and materials being transported. This flexibility allows businesses to select the most suitable scraper for their specific needs, ensuring optimal performance and reliability.

In conclusion, conveyor belt scrapers are a vital component of any material handling system. Their ability to remove adhering materials, improve efficiency, extend belt life, and customize to suit various applications make them an essential investment for businesses seeking to optimize their material handling operations. By incorporating scrapers into their conveyor systems, businesses can enjoy increased productivity, reduced downtime, and lower maintenance costs, resulting in a more efficient and profitable operation.

conveyor belt scraper. Over time, accumulated debris and materials can cause wear and tear on the belt, leading to premature failure. By regularly removing these materials, scrapers help prevent damage and extend the life of the belt, reducing replacement costs and maintenance downtime.

Moreover, conveyor belt scrapers can be customized to fit various conveyor systems and applications. Different types of scrapers are available for different belt widths, speeds, and materials being transported. This flexibility allows businesses to select the most suitable scraper for their specific needs, ensuring optimal performance and reliability.

In conclusion, conveyor belt scrapers are a vital component of any material handling system. Their ability to remove adhering materials, improve efficiency, extend belt life, and customize to suit various applications make them an essential investment for businesses seeking to optimize their material handling operations. By incorporating scrapers into their conveyor systems, businesses can enjoy increased productivity, reduced downtime, and lower maintenance costs, resulting in a more efficient and profitable operation. Next:

Latest news

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025

OUR PRODUCTS