Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu components of conveyor system

Components of a Conveyor System

Conveyor systems are essential in various industrial applications, designed to transport materials efficiently from one location to another. Understanding the components of these systems is crucial for optimizing their operation and enhancing productivity in manufacturing and logistics. This article will explore the primary components of a conveyor system, highlighting their functions and importance.

1. Conveyor Belts

The conveyor belt is perhaps the most recognizable component of a conveyor system. It serves as the surface that carries items from one point to another. Conveyor belts can be made from various materials, including rubber, plastic, or metal, depending on the type of material being transported and the environment in which the conveyor operates. The choice of belt material impacts durability, traction, and resistance to wear and tear.

2. Drive Unit

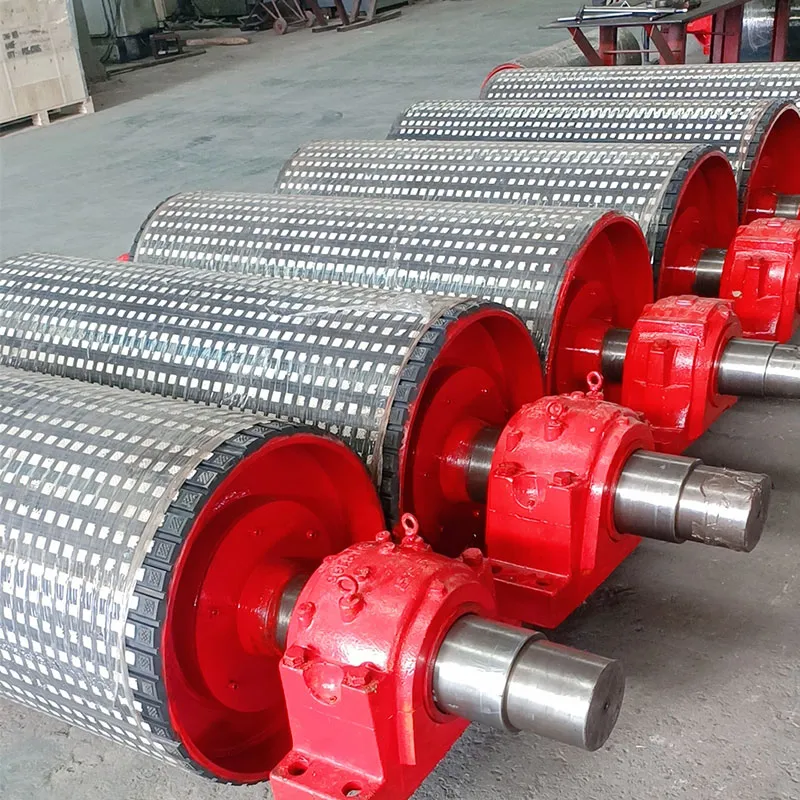

The drive unit is the heart of the conveyor system, providing the necessary power to move the belt. It typically consists of an electric motor, gear reducer, and coupling. The drive unit's design and size depend on the conveyor's length, load capacity, and speed requirements. Proper selection and maintenance of the drive unit are essential to ensure smooth and efficient operation.

Idlers and rollers support the conveyor belt along its length, helping it maintain structure and alignment. Idlers are stationary components that support the belt's weight, while rollers are mounted on the drive unit and help facilitate movement. These components reduce friction and convey the materials smoothly, enhancing efficiency.

components of conveyor system

4. Pulley System

Pulleys are crucial in changing the direction of the conveyor belt and maintaining tension. They are typically found at the drive unit and at the end of the conveyor run, where they help redirect the belt back to its starting point. Properly designed pulleys contribute to the longevity of the belt and the overall efficiency of the system.

5. Controls and Sensors

Modern conveyor systems are often equipped with advanced controls and sensors that monitor performance and ensure safety. Control systems automate the operation of the conveyor, adjusting speed or stopping when necessary. Sensors can detect jams, monitor load weight, and track the position of materials, providing real-time data that enhances efficiency and minimizes downtime.

6. Frames and Supports

The frame serves as the structural backbone of the conveyor system. It supports all other components, ensuring stability and alignment. It is typically made from steel or aluminum and can be customized to fit the specific application and environment. Robust frame design is crucial for accommodating heavy loads and ensuring safety.

Conclusion

In summary, the effectiveness of a conveyor system hinges on the seamless integration of its various components, including conveyor belts, drive units, idlers, pulleys, controls, and frames. Understanding each component's role is vital for maintaining optimal performance, ensuring safety, and achieving high productivity levels in industrial environments. As industries continue to evolve, advancements in conveyor system technology will play an increasingly significant role in shaping efficient manufacturing and logistics processes.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025