Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu जन . 30, 2025 05:59

Back to list

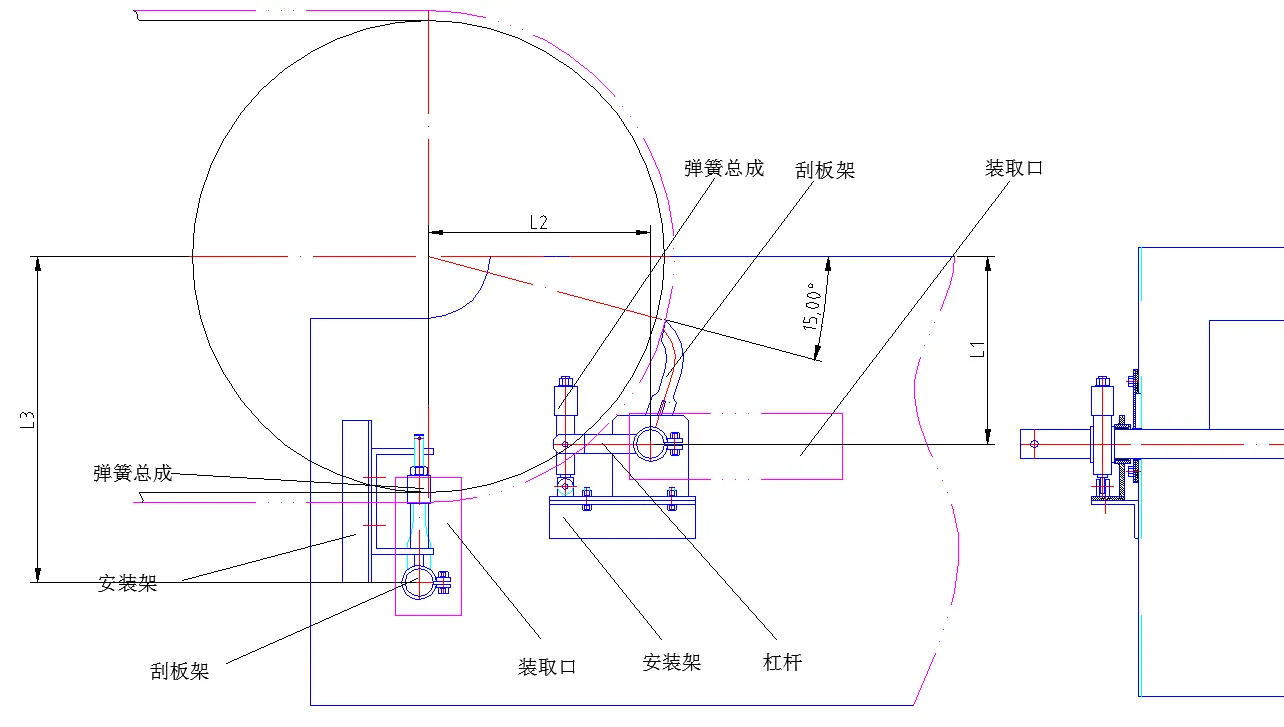

Return Idler Bracket

Navigating the intricate world of hardware components like rollers and brackets might seem a bit daunting at first. However, their significance in both residential and industrial mechanics is paramount. The functionality and durability of machinery, doors, and gates often rest upon these foundational elements. With expertise in this area, I've observed that an understanding of their design, materials, and specific uses can drastically improve efficiency and longevity in their applications.

Another aspect where expertise makes a significant difference is in understanding the specific types of rollers and brackets that suit particular applications. For instance, ball-bearing rollers offer superior motion fluidity and are perfect for precision devices, while flat belt rollers might be apt for bulk material handling. Similarly, adjustable brackets offer flexibility in applications where dimensional changes are anticipated, whereas fixed brackets provide sturdiness and are preferred for permanent structures. Despite the simplicity of rollers and brackets in theory, their impact is profound, influencing everything from operational efficiency to safety standards. Therefore, it's imperative to consider not only the immediate requirements but also long-term sustainability and ease of replacement. Engaging with manufacturers and suppliers known for their quality and innovation can further enhance the reliability and performance of these tools. Having spent years delving into the selection and implementation of these components, I recommend a strategic approach. Begin by assessing specific needs and constraints of your project. Consult industry guidelines and experienced professionals to identify the most suitable materials and design. Additionally, maintain a schedule for inspection and service; this not only assures safety but also enhances the component’s lifecycle. While technology evolves, the fundamental importance of rollers and brackets remains steadfast. Advancements in materials science and engineering continue to offer improved versions, yet the basic rotational and supportive functions are irreplaceable. Mastery over these components, then, equips one to handle a broad spectrum of mechanical and structural challenges with confidence. In conclusion, the efficacious use of rollers and brackets lies in understanding their capabilities and leveraging this knowledge towards creating efficient systems. Comprehensive research, coupled with real-world experience, ensures that these modest yet mighty components perform at their best. As automation progresses, a careful consideration of these elemental parts can yield substantial improvements in productivity and safety.

Another aspect where expertise makes a significant difference is in understanding the specific types of rollers and brackets that suit particular applications. For instance, ball-bearing rollers offer superior motion fluidity and are perfect for precision devices, while flat belt rollers might be apt for bulk material handling. Similarly, adjustable brackets offer flexibility in applications where dimensional changes are anticipated, whereas fixed brackets provide sturdiness and are preferred for permanent structures. Despite the simplicity of rollers and brackets in theory, their impact is profound, influencing everything from operational efficiency to safety standards. Therefore, it's imperative to consider not only the immediate requirements but also long-term sustainability and ease of replacement. Engaging with manufacturers and suppliers known for their quality and innovation can further enhance the reliability and performance of these tools. Having spent years delving into the selection and implementation of these components, I recommend a strategic approach. Begin by assessing specific needs and constraints of your project. Consult industry guidelines and experienced professionals to identify the most suitable materials and design. Additionally, maintain a schedule for inspection and service; this not only assures safety but also enhances the component’s lifecycle. While technology evolves, the fundamental importance of rollers and brackets remains steadfast. Advancements in materials science and engineering continue to offer improved versions, yet the basic rotational and supportive functions are irreplaceable. Mastery over these components, then, equips one to handle a broad spectrum of mechanical and structural challenges with confidence. In conclusion, the efficacious use of rollers and brackets lies in understanding their capabilities and leveraging this knowledge towards creating efficient systems. Comprehensive research, coupled with real-world experience, ensures that these modest yet mighty components perform at their best. As automation progresses, a careful consideration of these elemental parts can yield substantial improvements in productivity and safety.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS