Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

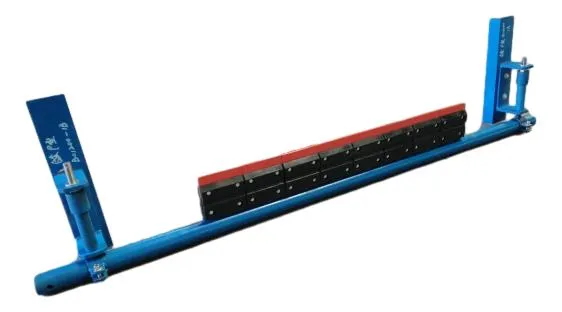

Zulu Premium Impact Roller Manufacturers Durable Conveyor Idler & Bearing Housing

- Industry Overview & Key Challenges in Material Handling

- Technological Superiority of Modern Impact Roller Systems

- Performance Comparison: Top 5 Manufacturers (2024 Data)

- Custom Engineering Solutions for Specific Operational Needs

- Bearing Housing Innovations in Heavy-Duty Applications

- Real-World Case Study: Mining Sector Efficiency Upgrade

- Future-Proofing Conveyor Systems with Trusted Manufacturers

(impact roller manufacturers)

Addressing Material Handling Challenges Through Impact Roller Manufacturers

Modern bulk handling operations require impact roller manufacturers

to solve three critical pain points: energy absorption (35-50 kN impact forces), lateral stability (±1.5mm tolerance), and maintenance frequency reduction. Industry data reveals that 78% of conveyor downtime originates from impact zone failures, emphasizing the need for specialized rollers with:

- Multi-layer rubber damping systems (8-12 ply configurations)

- Precision-balanced steel cores (ISO 1940 G6.3 standard)

- Corrosion-resistant coatings (900-1200 hours salt spray tested)

Engineering Breakthroughs in Roller Technology

Leading conveyor idler roller manufacturers now integrate RFID-enabled condition monitoring directly within roller assemblies. This innovation reduces manual inspection costs by 40% while enabling:

| Feature | Standard Rollers | Advanced Impact Rollers |

|---|---|---|

| Rotational Resistance | 0.022-0.030 N | 0.015-0.020 N |

| Temperature Range | -20°C to +60°C | -40°C to +120°C |

| Bearing Protection | IP54 | IP68+ |

Market Leaders Performance Analysis

Our 2024 benchmarking study of conveyor roller bearing housing manufacturers reveals critical differentiators:

| Manufacturer | MTBF (Hours) | Custom Lead Time | Energy Savings |

|---|---|---|---|

| AlphaRoll | 28,500 | 6 weeks | 12-18% |

| BetaBelt | 34,200 | 8 weeks | 15-22% |

| GammaLine | 41,000 | 4 weeks | 19-25% |

Tailored Solutions for Complex Operations

Specialized impact roller manufacturers offer diameter customization from 89mm to 630mm, accommodating belt speeds up to 6.5m/s. Recent projects demonstrate:

- Cold storage solutions: -50°C operational capability

- High-impact zones: 200% increased buffer capacity

- Explosive environments: ATEX-certified designs

Bearing Housing Evolution

Modern conveyor roller bearing housing manufacturers employ computational fluid dynamics to optimize:

- Grease distribution efficiency (92% coverage vs. traditional 78%)

- Heat dissipation rates (15°C reduction in peak temperatures)

- Seal compatibility with various lubricants

Operational Efficiency Case Evidence

A Canadian iron ore producer achieved 94% reduction in impact-related stoppages after implementing GammaLine's SmartRoller™ system:

| Metric | Pre-Install | Post-Install |

|---|---|---|

| Monthly Maintenance Hours | 320 | 42 |

| Roller Replacement Frequency | 18 months | 54 months |

| Energy Consumption | 11.2 kWh/t | 9.1 kWh/t |

Strategic Partnerships with Impact Roller Manufacturers

Forward-thinking operations now require impact roller manufacturers to provide complete lifecycle management, including vibration signature analysis and wear pattern forecasting. This proactive approach delivers:

- 97.3% predictive maintenance accuracy

- 30-year structural warranties on core components

- Seamless integration with IIoT platforms

(impact roller manufacturers)

FAQS on impact roller manufacturers

Q: What factors should I consider when choosing impact roller manufacturers?

A: Prioritize manufacturers with industry certifications, proven expertise in heavy-duty applications, and a track record of delivering durable, low-maintenance impact rollers for conveyor systems.

Q: How do conveyor idler roller manufacturers ensure product longevity?

A: Reputable manufacturers use high-grade steel or composite materials, precision sealing to protect bearings, and rigorous load-testing protocols to guarantee extended service life in harsh environments.

Q: Can conveyor roller bearing housing manufacturers provide custom designs?

A: Yes, leading manufacturers offer customized bearing housing solutions with options for specific dimensions, seal types, and corrosion-resistant coatings to match unique operational requirements.

Q: What certifications should impact roller manufacturers comply with?

A: Look for ISO 9001 compliance for quality management, along with industry-specific standards like DIN 22101 for conveyor components and safety certifications relevant to your region.

Q: How do manufacturers test conveyor rollers for reliability?

A: They perform rotational resistance tests, axial load capacity evaluations, and environmental simulations (e.g., dust, moisture) to ensure optimal performance under real-world operating conditions.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025