Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor belt parts and functions

Conveyor Belt Parts and Functions

Conveyor belts play a critical role in various industries, serving as essential components for material handling and transportation. Understanding the parts of a conveyor belt and their functions can help optimize its performance and improve operational efficiency.

1. Belt Material The conveyor belt itself is typically made from various materials, such as rubber, plastic, metal, or fabric, depending on the specific application. Each material has distinct properties that affect flexibility, durability, and resistance to wear and abrasion.

2. Pulleys Pulleys are cylindrical components located at both ends of the conveyor belt. They serve to drive the belt and help to redirect it. The drive pulley is powered by a motor, creating movement, while the return pulley allows the belt to return to its starting position. Pulleys are essential for maintaining the tension and alignment of the belt.

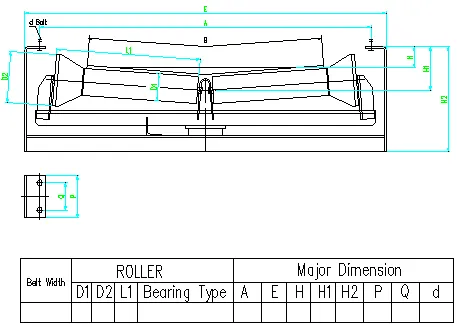

3. Idlers Idlers are rollers that support the conveyor belt along its path. They are strategically placed to minimize sagging and friction, ensuring smooth movement. There are various types of idlers, including trough, flat, and return idlers, each designed to cater to specific load and operational conditions.

conveyor belt parts and functions

4. Conveyor Frame The conveyor frame provides the structural support needed to hold the entire system together. It is usually made from steel or aluminum, and its design must accommodate the weight of materials being transported while maintaining stability.

5. Drive System The drive system is integral to conveyor belt operations, typically consisting of an electric motor, gearbox, and associated components that deliver power to the drive pulley. This system determines the speed and efficiency of the belt's movement.

6. Belt Fasteners To connect the ends of the conveyor belt, fasteners are used. These can be mechanical, such as clips, or adhesive. Proper fastening is crucial to prevent slippage and ensure the belt operates correctly.

7. Sensors and Controls Modern conveyor systems often incorporate sensors and automated controls to monitor performance and adjust speed or direction as needed. These additions enhance safety and efficiency, allowing for real-time troubleshooting and monitoring.

In conclusion, each part of a conveyor belt system plays a vital role in its overall functionality. Understanding these components and their functions is essential for maintaining and optimizing conveyor systems in various industrial applications, from manufacturing to logistics. By ensuring that all parts are in good working order, businesses can enhance productivity and minimize downtime.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025