Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Inggeris

Inggeris  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Importance of Wing Pulley and Bend Pulley in Industrial Applications

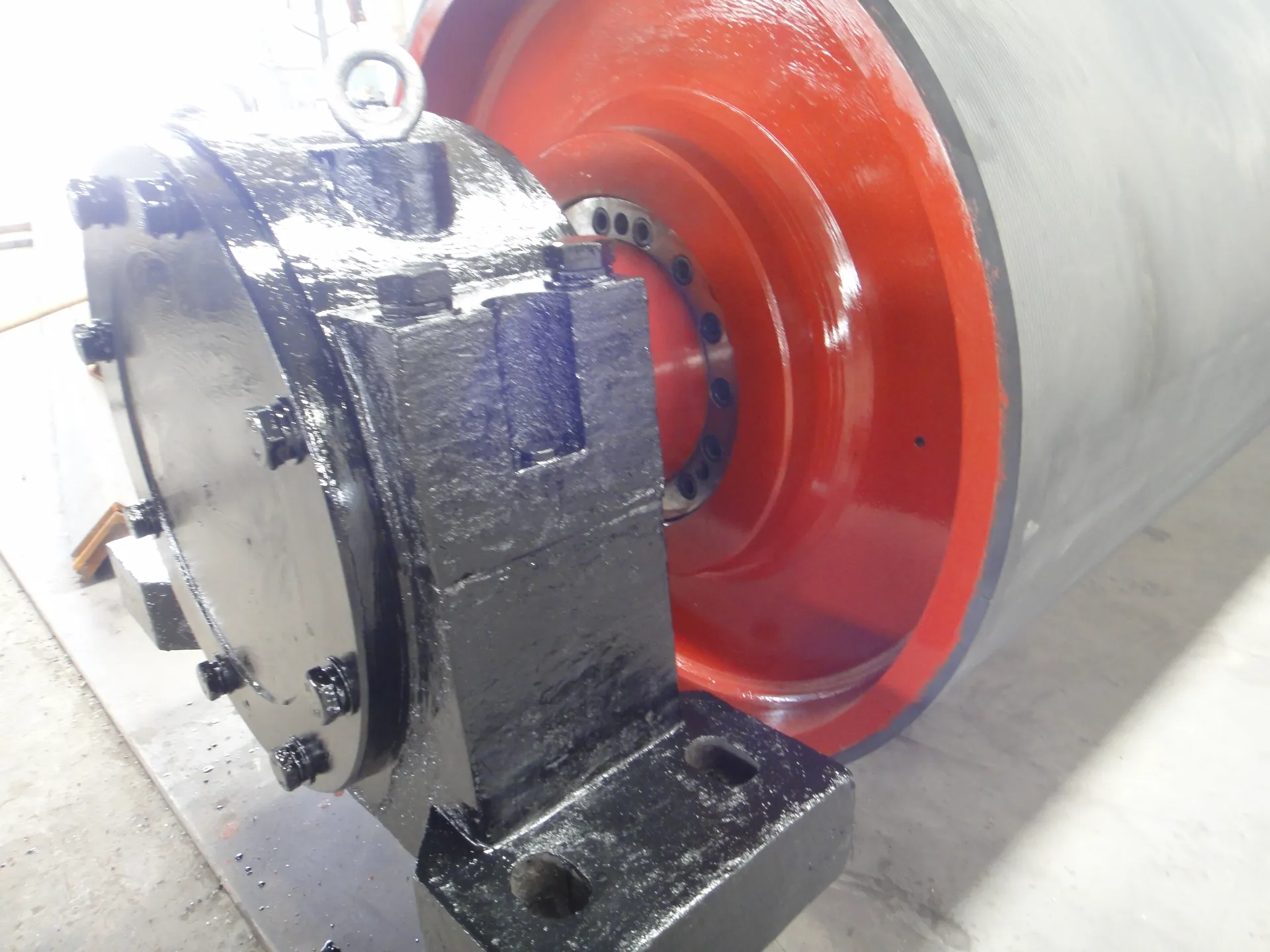

In the world of conveyor systems, both wing pulley and bend pulley play essential roles in enhancing efficiency and maintaining stability. These components ensure that conveyor belts operate smoothly, reducing wear and extending the lifespan of the system. Their application is especially crucial in industries like coal mining, where durable and reliable equipment is paramount. Let’s explore the significance of conveyor wing pulley and bend pulley, as well as compare their benefits and suitability for heavy-duty environments.

The Role of Wing Pulley

A wing pulley is designed to reduce the buildup of material between the pulley and the conveyor belt. By allowing debris and other materials to escape through the gaps in the wings, conveyor wing pulleys minimize wear and tear on both the pulley and the belt. This self-cleaning mechanism not only prevents material from accumulating but also reduces belt slippage, ensuring a more efficient operation.

The unique design of the wing pulley makes it ideal for applications where materials like coal, gravel, or other abrasive substances are handled. The wings of the pulley create channels for the material to exit, preventing damage to the belt and extending its life.

The Role of Bend Pulley

A bend pulley is primarily used to change the direction of the conveyor belt. Positioned at different points along the conveyor system, bend pulleys help to adjust the belt's angle, ensuring smooth transitions between sections. Unlike the wing pulley, the bend pulley is not self-cleaning but plays a critical role in maintaining belt alignment and tension.

In coal mining and other heavy industries, bend pulleys are used to direct conveyor belts around corners or to adjust the belt’s path as needed. This pulley is essential for maintaining the correct tension in the belt, which is crucial for efficient material transport.

Bend Pulley vs. Wing Pulley: Who Is More Suitable for the Coal Mining Industry?

When comparing bend pulley vs. wing pulley for coal mining applications, both have their advantages. However, each type of pulley serves a different purpose, making them suitable for specific tasks within the mining industry.

For example, conveyor wing pulleys are particularly beneficial in environments where debris accumulation is a concern. The self-cleaning design of the wing pulley makes it perfect for coal mining, as it prevents material buildup that could otherwise cause belt slippage or damage. This feature enhances productivity by reducing the need for maintenance and ensuring continuous operation.

On the other hand, bend pulleys are crucial for redirecting the conveyor belt around the mining site. While they don't offer the same self-cleaning properties as wing pulleys, their role in maintaining belt tension and alignment is vital for ensuring smooth transportation of coal.

Bend Pulley vs. Wing Pulley: Various Advantages

When comparing the advantages of bend pulley vs. wing pulley, each offers distinct benefits.

Wing pulleys are known for their ability to handle challenging environments with heavy material loads. The self-cleaning feature ensures minimal maintenance and reduces the risk of belt slippage. This makes them ideal for industries like coal mining, where debris and material accumulation can significantly impact performance.

Bend pulleys, on the other hand, excel in their ability to change the direction of conveyor belts smoothly. They ensure that belts maintain the correct tension and alignment, preventing potential disruptions to the conveyor system. In applications where the conveyor belt needs to navigate tight corners or complex paths, the bend pulley is an indispensable component.

Both pulleys offer unique advantages, and their use depends on the specific needs of the conveyor system. While wing pulleys excel in preventing material buildup, bend pulleys are essential for guiding belts through various angles and maintaining operational efficiency.

Why Choose the Right Pulley for Your Conveyor System?

Selecting the right pulley, whether it’s a conveyor wing pulley or a bend pulley, can significantly impact the overall performance of your conveyor system. For coal mining and other industries that rely heavily on material handling systems, the choice between these pulleys will depend on factors like material type, operational environment, and conveyor design.

By understanding the distinct roles of wing pulley and bend pulley, you can ensure that your conveyor system operates efficiently, reducing downtime and extending the lifespan of the belt. Both pulleys play critical roles in ensuring smooth, reliable operation, but selecting the right one for your specific needs is key to maximizing productivity.

In conclusion, whether you need the self-cleaning properties of a wing pulley or the directional guidance of a bend pulley, both components are vital in enhancing conveyor system performance, especially in demanding industries like coal mining.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysBeritaJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsBeritaJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesBeritaJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysBeritaJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerBeritaJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersBeritaJul.22,2025