Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

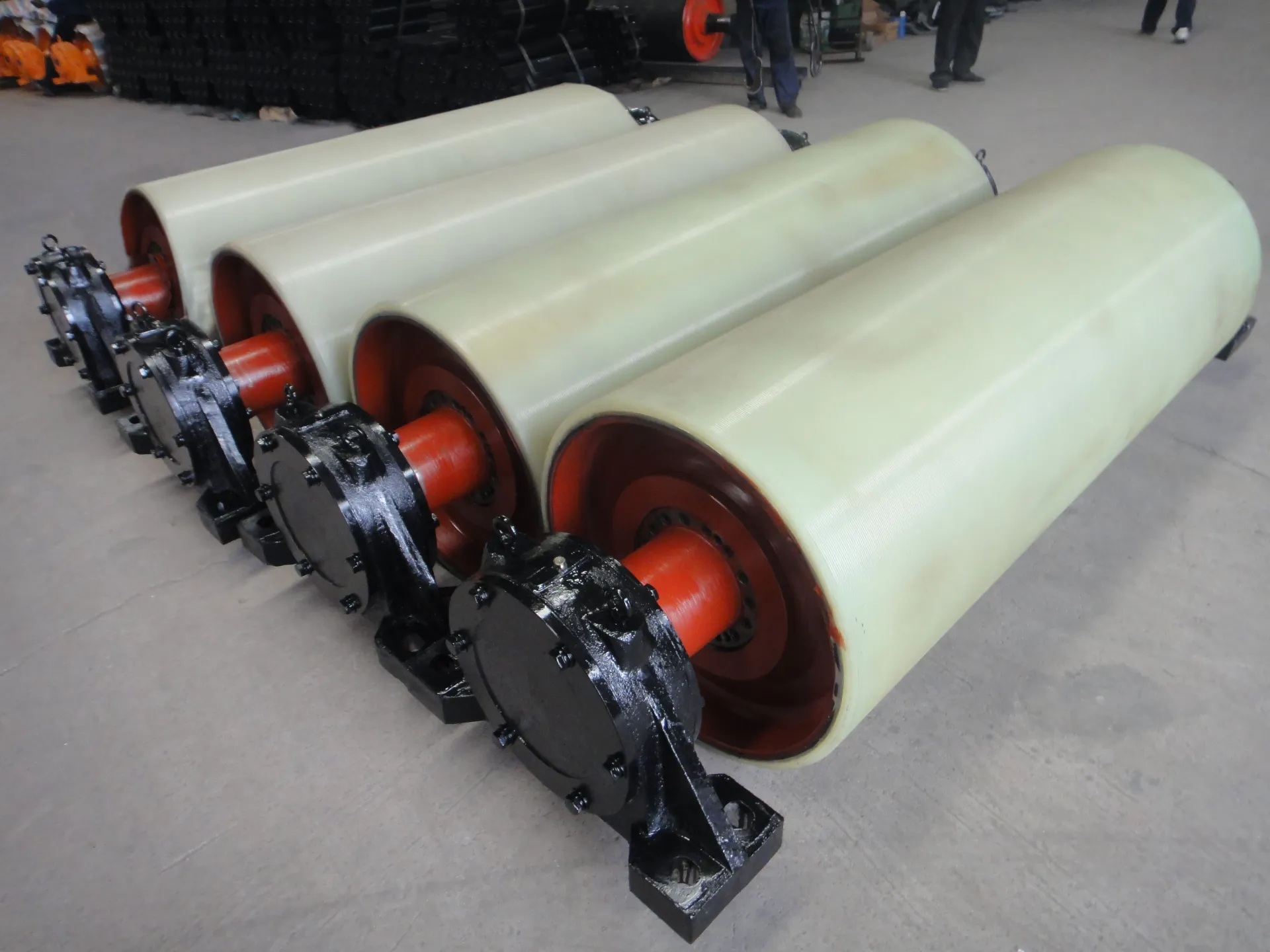

Zulu urethane coated rollers

The Advantages of Urethane Coated Rollers in Various Industries

Urethane coated rollers have become a crucial component across various industries, offering durability, flexibility, and performance that other coatings simply cannot match. As manufacturing processes evolve to meet ever-increasing demands for quality and efficiency, urethane coated rollers have emerged as an optimal solution. This article explores the properties, benefits, and applications of urethane coated rollers, demonstrating why they are a preferred choice in many sectors.

What are Urethane Coated Rollers?

Urethane coated rollers are cylindrical devices that are covered with a layer of polyurethane, a synthetic polymer. The coating process involves pouring or applying polyurethane onto a metal or composite base roller. Once cured, the urethane forms a robust and resilient barrier that enhances the roller's characteristics. The final product exhibits excellent resistance to wear and tear, making it suitable for various industrial applications.

Key Properties of Urethane Coated Rollers

1. Durability Urethane is well-known for its extraordinary resistance to abrasion and impact. This makes urethane coated rollers an ideal solution for high-traffic environments where equipment is prone to wear.

2. Chemical Resistance Urethane provides protection against a wide range of chemicals, oils, and solvents. This property is particularly beneficial in industries such as food processing and pharmaceuticals, where contamination control is paramount.

3. Flexibility and Elasticity The inherent flexibility of urethane allows for shock absorption and noise reduction during operation. This characteristic minimizes vibration and stress on machinery, extending the lifespan of both the roller and the equipment in which it is used.

4. Customization Urethane coatings can be tailored to meet specific application requirements, including hardness, thickness, and color. This level of customization makes urethane coated rollers suitable for various uses, from gentle handling of delicate materials to more robust applications.

5. Low Friction Coefficient Urethane surfaces have a relatively low friction coefficient, reducing the energy required for movement and enhancing efficiency in operations.

urethane coated rollers

Applications of Urethane Coated Rollers

Urethane coated rollers find applications in a multitude of industries due to their versatility

1. Printing Industry Rollers in printing presses often face harsh conditions, including high speeds and chemical exposure. Urethane coated rollers provide the durability needed to maintain printing quality while ensuring a longer service life.

2. Food and Beverage In food processing, hygiene and resistance to contamination are critical. Urethane's chemical and abrasion resistance make it an ideal choice for rollers used in processing and transporting food products.

3. Conveyor Systems In material handling systems, urethane coated rollers reduce wear on both the rollers and the materials being transported. The flexibility and shock-absorbing properties also contribute to smoother operations and enhanced product integrity.

4. Textile Industry Urethane rollers are used in weaving and finishing operations. Their ability to handle delicate fabrics without causing damage makes them essential in textile manufacturing.

5. Automotive In automotive manufacturing, urethane coated rollers play a significant role in the assembly and transportation of components, ensuring that parts are handled carefully and efficiently.

Conclusion

The incorporation of urethane coated rollers into industrial processes offers numerous advantages that enhance productivity, reduce costs, and improve product quality. Their unique properties make them a superior choice over traditional roller materials, particularly in demanding environments. As industries continue to seek innovative solutions to improve efficiency and performance, urethane coated rollers will undoubtedly remain at the forefront, catering to the evolving needs of various sectors.

In summary, whether in printing, food processing, material handling, textiles, or automotive applications, the benefits of urethane coated rollers are clear. Their durability, flexibility, chemical resistance, and customizability not only streamline operations but also contribute to long-term savings and operational excellence. As technology advances, we can expect the role of urethane coated rollers to expand, solidifying their place as an essential component in modern manufacturing processes.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025