Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu types of take up pulley

Types of Take-Up Pulleys

Take-up pulleys play a crucial role in various mechanical systems, particularly in conveyor belt applications. By providing tension and allowing for the adjustment of belts, take-up pulleys ensure smooth operation and extend the life of the belt drive. Understanding the different types of take-up pulleys is essential for selecting the right one for a specific application. This article explores the various types of take-up pulleys, their features, and applications.

1. Fixed Take-Up Pulleys

Fixed take-up pulleys are the simplest form of take-up mechanism. They are mounted firmly and do not allow for any adjustment in tension. This type is typically found in systems where the belt length is predetermined and does not require frequent adjustments. Fixed take-up pulleys are often made of durable materials to withstand the operational stresses they encounter.

*Applications* These are commonly used in installations where the operating conditions are stable, such as in assembly lines or other manufacturing processes where the belts maintain a consistent length.

2. Adjustable Take-Up Pulleys

Adjustable take-up pulleys allow for modifications in belt tension through an adjustable mechanism that can accommodate changes in length or sag due to wear and tear. This type is often mounted on a bracket, which can be moved to adjust the tension. Some systems may incorporate a screw mechanism that allows for precise adjustments.

*Features* The ability to adjust tension helps in maintaining optimal performance, reducing the risk of belt slippage, and prolonging belt life.

*Applications* Adjustable take-up pulleys are widely used in industries where changes in load and length are frequent, such as mining, agricultural applications, and material handling.

Automatic take-up pulleys are designed to maintain constant tension in the belt without manual intervention. These systems use a spring-loaded mechanism or a hydraulic system that automatically adjusts the tension as the belt wears or stretches. This type of take-up pulley helps to minimize downtime by reducing the need for regular maintenance and adjustments.

types of take up pulley

*Features* Automatic take-up pulleys contribute to enhanced efficiency and reliability in operations, as they automatically compensate for any variations.

*Applications* They are particularly beneficial in continuous operation applications, such as power plants, where consistent performance is crucial.

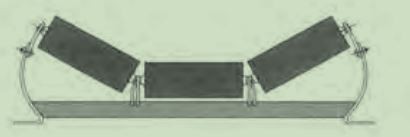

4. Gravity Take-Up Pulleys

Gravity take-up pulleys rely on a weight assembly to create tension in the belt. The pulley is mounted on a frame with a weight that can move vertically, allowing the take-up to adjust as the belt stretches. This type of system is effective in applications where fluctuations in tension occur due to varying loads.

*Features* Gravity take-up solutions are often simpler and cheaper than other automatic systems but require more space due to the need for weight movement.

*Applications* Often found in bulk handling industries, such as quarries and mining, where conveyor belts are subjected to heavy loads.

5. Snub Pulleys

Snub pulleys are not traditional take-up pulleys but are often used in conjunction with them. They help increase the arc of contact between the belt and the driving pulley, enhancing grip and tension. While they don't directly adjust tension, they assist in ensuring that the system operates effectively.

*Applications* Snub pulleys are used in various settings where improved belt stability is necessary, such as in steep incline conveyors or where changes in direction occur.

Conclusion

The choice of the appropriate take-up pulley is vital in ensuring the efficiency, safety, and longevity of any belt-driven system. Factors such as the application, load conditions, and required adjustments dictate the type of take-up pulley that should be used. Fixed, adjustable, automatic, gravity, and snub pulleys all serve unique purposes in enhancing the performance of conveyor systems. Understanding these differences enables engineers and operators to make informed decisions, leading to improved operational efficiency and reduced maintenance costs in the long run. Proper selection and maintenance of take-up pulleys not only optimize the machinery’s performance but also contribute to a safer working environment in various industrial applications.

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025