Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu rubber disc return idlers

Rubber Disc Return Idlers Enhancing Conveyor Efficiency

Conveyor systems play a crucial role in various industries, from mining to manufacturing, enabling the efficient transportation of materials over considerable distances. Among the key components that contribute to the performance and longevity of these systems are return idlers. Specifically, rubber disc return idlers are gaining significant traction due to their unique features and advantages, which enhance conveyor efficiency and operational reliability.

What are Rubber Disc Return Idlers?

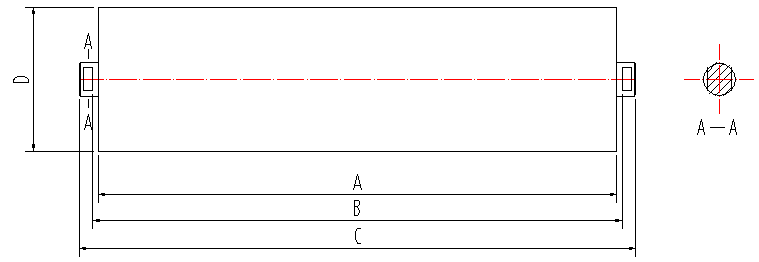

Rubber disc return idlers are specialized components designed to support the return belt of a conveyor system. Unlike conventional idlers that are usually made of steel or plastic, rubber disc idlers feature multiple rubber discs mounted on a rotating shaft. These discs generate a cushioning effect, allowing the belt to return smoothly along its trajectory. The design minimizes friction between the belt and the idler, which not only reduces wear and tear on the belt but also lowers the energy consumption of the system.

Benefits of Using Rubber Disc Return Idlers

1. Reduced Friction and Wear The primary advantage of rubber disc return idlers lies in their ability to minimize friction between the conveyor belt and the idler. This is crucial for prolonging the lifespan of the conveyor belt, as high friction can lead to faster degradation and costly replacements. Reduced wear also contributes to lower maintenance costs, enhancing overall operational efficiency.

2. Noise Reduction The use of rubber as a material significantly dampens vibrations and noise generated during the operation of conveyor systems. This is especially important in industries where noise pollution is a concern. By incorporating rubber disc return idlers, companies can create a quieter working environment, leading to improved worker comfort and satisfaction.

rubber disc return idlers

3. Enhanced Traction The rubber surface of the discs provides better traction for the conveyor belt. This enhances the stability of the belt, especially during the return phase, preventing slippage and ensuring that the materials are transported consistently. Better traction translates to fewer operational disruptions and an overall increase in productivity.

4. Adaptability to Various Conditions Rubber disc return idlers are adaptable to a range of environmental conditions. They can perform well in wet, dry, or even abrasive environments, making them suitable for various applications, including mining, cement, and bulk material handling. Their versatility ensures that they can be deployed in diverse operational settings without compromising performance.

5. Easy Installation and Maintenance These idlers are designed for easy installation and minimal maintenance. The straightforward design allows for quick replacements when necessary, which is essential for reducing downtime in production processes. Moreover, their robust construction means they require less frequent attention than more fragile idler options.

Applications in Various Industries

Rubber disc return idlers can be utilized across multiple industries, demonstrating their versatility and effectiveness. In mining, they are essential for transporting minerals and ores efficiently. In the manufacturing sector, they contribute to the smooth movement of materials, enhancing production lines. Furthermore, in the agriculture industry, they help in the transport of bulk grains, seeds, and fertilizers, directly affecting productivity and profitability.

Conclusion

In summary, rubber disc return idlers are an innovative solution that enhances the efficiency and reliability of conveyor systems. Their ability to reduce friction, noise, and wear makes them an attractive option for various industries seeking to optimize their operations. As businesses continue to strive for greater efficiency and cost-effectiveness, the adoption of advanced components like rubber disc return idlers will likely become increasingly important. By investing in these advanced idlers, companies not only improve their conveyor systems but also contribute to a more sustainable and productive industrial landscape. Whether in mining, manufacturing, or agriculture, rubber disc return idlers are an integral part of a well-functioning conveyor system, leading the way in the transportation of materials effectively and efficiently.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025