Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Durable Support Bracket for Conveyor Rollers Ideal for Heavy Load Conveying Applications

Understanding Conveyor Roller Brackets Key Components in Material Handling Systems

In the realm of material handling systems, conveyor belts play a crucial role in automating the movement of goods and materials across various industries. At the heart of these conveyor systems are several pivotal components, one of which is the conveyor roller bracket. This article aims to explore the significance, design, and various applications of conveyor roller brackets, highlighting their essential role in ensuring efficient and reliable conveyor operations.

What is a Conveyor Roller Bracket?

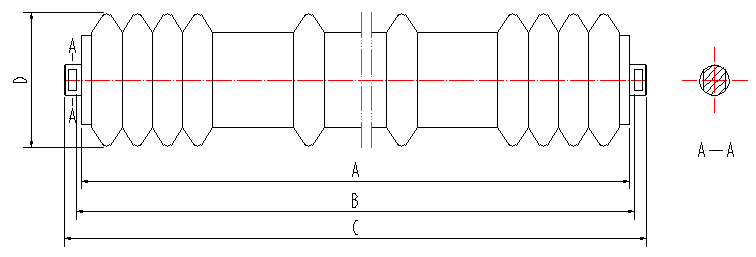

A conveyor roller bracket is a structural element that supports the conveyor rollers, which are the cylindrical components that facilitate the movement of materials along the conveyor belt. These brackets are designed to hold the rollers securely in place while allowing them to rotate freely. Proper alignment and stability provided by the roller brackets are crucial for the smooth operation of any conveyor system.

Importance of Conveyor Roller Brackets

1. Stability and Support Conveyor roller brackets are engineered to provide maximum stability to the rollers. Stable roller positions prevent roller misalignment that can lead to increased wear and tear on the conveyor system, inefficient operation, and potentially costly downtime.

2. Load Distribution The brackets play a vital role in the load distribution on conveyor systems. They help in evenly spreading the weight of the materials being transported across the rollers, which is essential for preventing overload on individual rollers and extending the lifespan of both rollers and brackets.

3. Ease of Maintenance Many brackets are designed for easy installation and maintenance, allowing for quick replacement or adjustment of rollers. This feature is particularly valuable in industrial settings, where downtime can have significant financial consequences.

4. Adaptability and Versatility Conveyor roller brackets come in various designs to accommodate different roller sizes, types, and conveyor configurations. This versatility ensures that they can be adapted for numerous applications across different industries, including agriculture, manufacturing, and logistics.

Design Considerations

When designing or selecting conveyor roller brackets, several factors come into play

conveyor roller bracket

1. Material Selection Brackets are usually made from robust materials such as steel or aluminum, which provide the necessary strength to withstand the harsh conditions often found in industrial environments.

2. Weight Capacity It's crucial to choose roller brackets that can handle the specific load capacity required for the materials being conveyed. Failing to do so could lead to bracket failure and disrupt operations.

3. Environmental Factors In environments where exposure to moisture, chemicals, or extreme temperatures is common, selecting corrosion-resistant materials or coatings for the roller brackets is essential to enhance their longevity.

4. Installation and Adjustment Some roller brackets feature adjustable designs, enabling operators to modify their height or angle to align with the conveyor’s operational requirements. This adjustability can significantly enhance overall system performance.

Applications Across Industries

Conveyor roller brackets are utilized in a variety of applications across numerous industries

- Manufacturing In manufacturing plants, these brackets support conveyors that transport components from one assembly station to another, ensuring a steady flow of materials. - Logistics and Warehousing In distribution centers, conveyor systems equipped with roller brackets facilitate the efficient movement of goods from storage to shipping areas, streamlining order fulfillment processes.

- Mining and Agriculture In sectors such as mining and agriculture, robust roller brackets support severe-duty conveyors that transport bulk materials, ensuring efficiency even in the most challenging conditions.

Conclusion

In conclusion, conveyor roller brackets serve as an integral component in the functionality and efficiency of conveyor systems. Their importance cannot be overstated, as they contribute to the stability, load distribution, and adaptability of conveyor operations. By understanding the significance of these brackets, industries can make informed decisions about their material handling systems, ultimately optimizing productivity and ensuring smooth operations. Investing in high-quality roller brackets is not just a matter of maintenance; it's a strategic decision that can lead to substantial long-term benefits for any organization reliant on conveyor systems.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025